Bag Labeling Machine for Efficient Packaging

Bag Labeling Machine Category Overview

Streamline Your Packaging with YUANYANG Bag Labeling Machines

YUANYANG offers high-performance bag labeling machines designed to boost productivity and accuracy in your packaging line. Engineered for various industries, our machines deliver precise and rapid label application, ensuring each product adheres to stringent quality standards. Choose YUANYANG for a cost-effective, reliable solution that streamlines operations and enhances YUANYANG presentation.

Key Features of YUANYANG Bag Labeling Machines

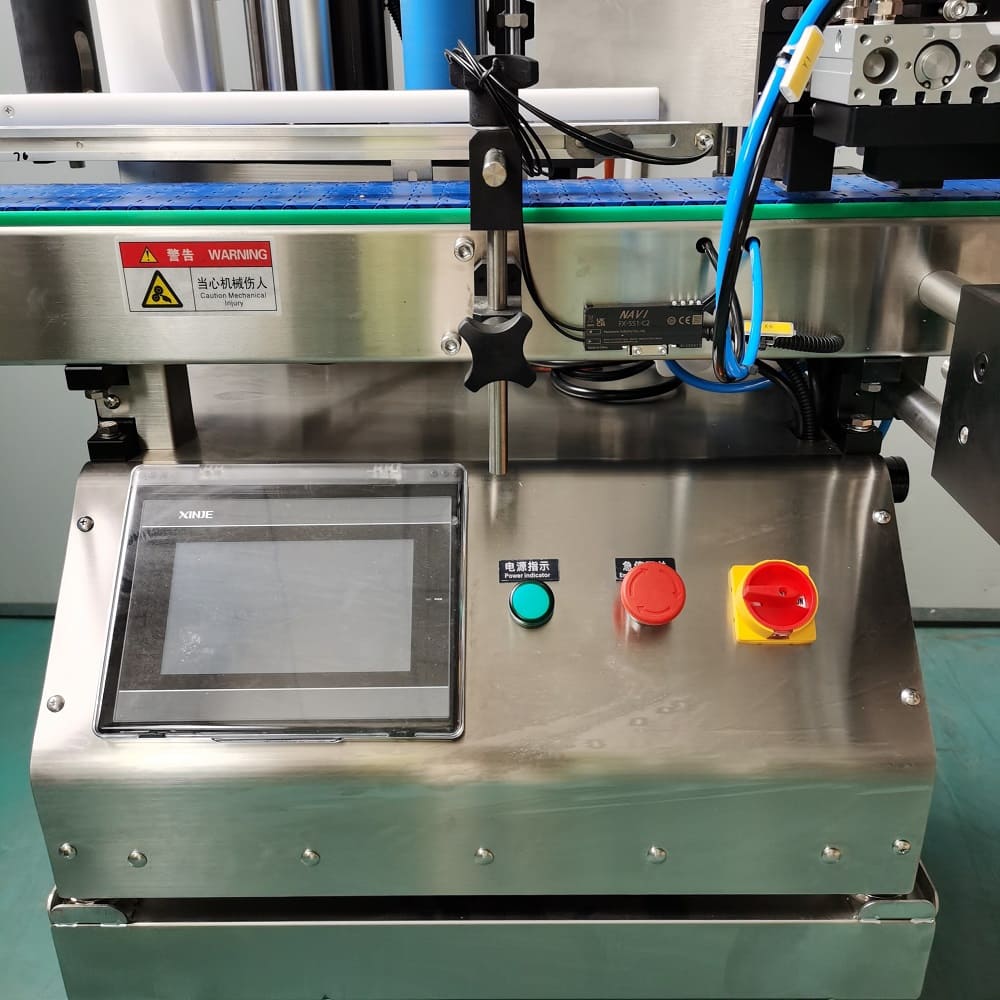

Our bag labeling machines feature smart sensors, adjustable speed controls, and robust labeling mechanisms. Compatible with different bag materials and sizes, they guarantee smooth, wrinkle-free application. Enhanced with intuitive touch-screen interfaces, our machines are user-friendly and allow quick setup for new production runs, reducing downtime and human error.

Wide Application and Industry Versatility

YUANYANG’s bag labeling machines are suitable for industries ranging from food and beverage to pharmaceuticals, cosmetics, and chemicals. Whether labeling pouches, sachets, or larger bags, our solutions ensure perfectly aligned, durable labels every time. Enhance shelf appeal and comply with regulatory requirements easily with YUANYANG’s advanced technology.

Reliable After-Sales Service and CE Certification

Benefit from free technical training and comprehensive support for turnkey production lines. All YUANYANG equipment, including our bag labeling machines, comes with CE certification, assuring you of compliance with European safety and health standards. Rely on our experienced team for seamless installation and maintenance worldwide.

Why Choose YUANYANG Bag Labeling Machine?

With over 15 years of expertise, YUANYANG stands out as a trusted partner for industrial automation. Our bag labeling machines are engineered to maximize efficiency, accuracy, and ROI. Invest in YUANYANG for unwavering performance and collaborative support at every step of your packaging journey.

bag labeling machine Display

What’s the maximum and minimum height can the automatic sealing machine lift up and go down?

The maximum height for the sealing head to the floor is 75-120cm.

What type of water can we use for this pure water filter ?

The raw quality (conductivity) should be ≤300μs/cm), such as city tap water, lake water, underground water, river water...

Does Yuanyang’s pharmaceutical equipment comply with GMP standards?

Yes, all of Yuanyang’s pharmaceutical equipment complies with Good Manufacturing Practice (GMP) standards, ensuring quality and hygiene at every production stage, meeting the requirements of global pharmaceutical regulatory agencies.

Does the stainless steel mixing tank for liquid soap has jacket?

The mixing tank can be customized single layer, double layers, or three layers. The double layers type has one jacket for cooling purpose. The three layers type has double jacket, inner jacket for heating/cooling, outer jacket for insulation and protection purpose.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery