Elevate Your Cosmetic Production with YUANYANG Cosmetic Mixing Heating Tanks

Elevate Your Cosmetic Production with YUANYANG Cosmetic Mixing Heating Tanks

In the dynamic world of cosmetics, precision, purity, and consistency are paramount. To achieve the silky textures, stable emulsions, and perfect blends that captivate consumers, an advanced cosmetic mixing heating tank is indispensable. YUANYANG, a leading manufacturer of industrial mixers and agitators in China since 2008, offers cutting-edge solutions designed to optimize your cosmetic production processes, ensuring superior product quality and operational efficiency.

The Core of Quality Cosmetic Manufacturing

A high-performance cosmetic mixing heating tank is more than just a container; it's the heart of your product formulation. These specialized tanks provide precise temperature control and powerful mixing capabilities, crucial for dissolving ingredients, creating stable emulsions, and maintaining product integrity. Whether you're producing lotions, creams, shampoos, or serums, our tanks facilitate homogeneous blending, preventing separation and ensuring a consistent user experience batch after batch.

YUANYANG's Unmatched Expertise in Mixing Solutions

With over a decade of experience, YUANYANG stands as a trusted name in industrial mixing. Our expertise extends beyond individual machines; we provide complete production line equipment, including mixing, storage, filling, capping, and labeling solutions. Leveraging our core strength in vacuum homogenizers, vacuum emulsifying mixers, and high shear mixers, our cosmetic mixing heating tanks are engineered to seamlessly integrate into your workflow, from ingredient preparation to final product storage. We understand the nuances of cosmetic chemistry and engineer our tanks to meet the highest industry standards.

Advanced Features for Superior Performance

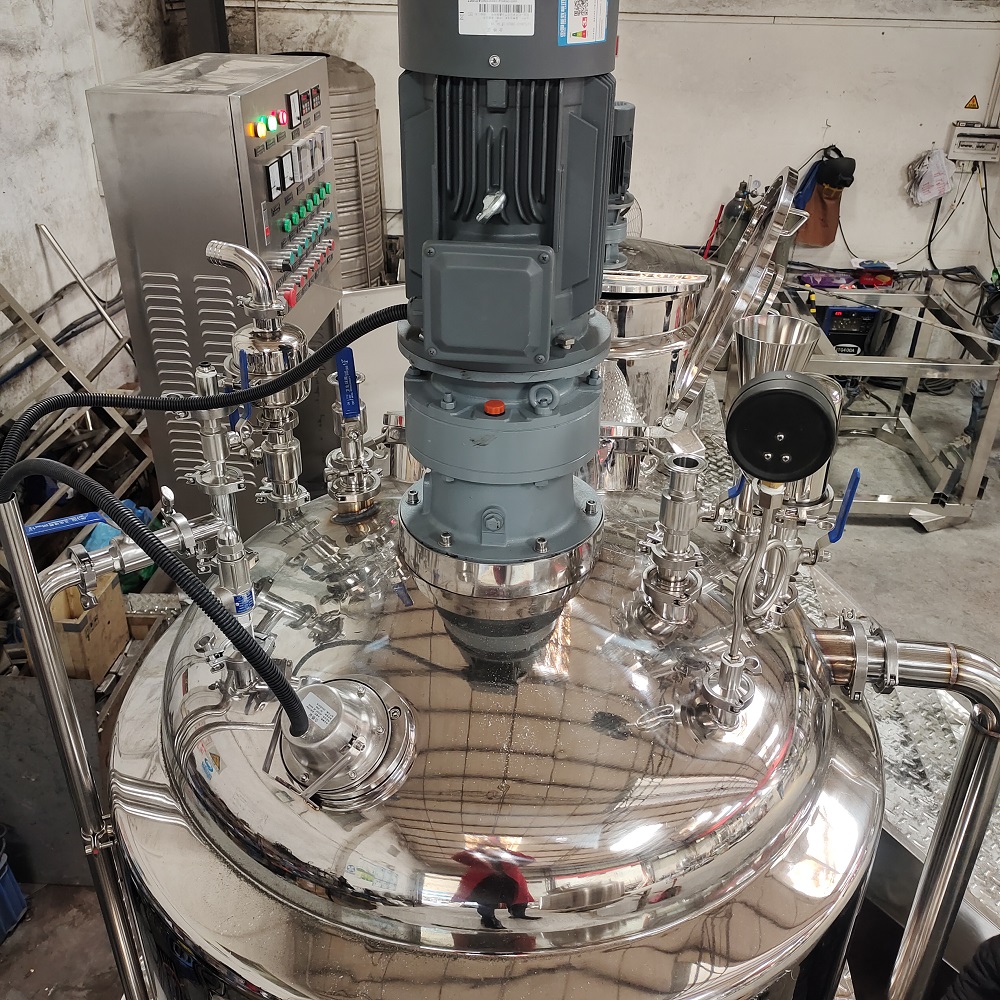

YUANYANG's cosmetic mixing heating tanks are meticulously designed with your needs in mind. Each tank boasts robust construction, ensuring durability and longevity. Equipped with precise heating and cooling systems, advanced agitation mechanisms, and intuitive controls, they provide the flexibility required for diverse cosmetic formulations. Our commitment to quality is underscored by our multiple CE certifications, signifying adherence to European safety and health standards. When you choose YUANYANG, you invest in reliability and performance.

Comprehensive Support and Turnkey Solutions

At YUANYANG, we believe in empowering our clients. Beyond delivering world-class equipment, we offer unparalleled support. From free technical training to one-stop installation assistance, our dedicated team ensures a smooth setup and operation. Our comprehensive full set of turnkey services means we handle every detail, allowing you to focus on innovation and market growth.

Partner with YUANYANG for Cosmetic Manufacturing Excellence

Our vision is clear: to become the best industrial mixer and agitator manufacturer in the world. By choosing YUANYANG for your cosmetic mixing heating tank needs, you are partnering with a company committed to engineering excellence, operational efficiency, and unwavering customer support. Discover how our solutions can transform your cosmetic production. Visit www.yuanymachinery.com to explore our full range of innovative equipment.

cosmetic mixing heating tank Display

Can I use city water to produce liquid detergent?

As you know, water takes 70-99% proportion of raw materials for liquid detergent production. So the quality of water is quite important to produce qualified liquid cleaning products. The raw water should be treated before taking into tank.

Can the pipe of the powder feeding machine be customized

Yes, the pipe size can be customized according to materials.

What material can the piston filling machine fill?

The piston filler can fill a variety of viscous liquids and pastes, such as laundry detergent, shampoo, hair conditioner, toothpaste, gel water, aloe vera gel, lotion and other washing and care products, honey, loquat paste, mother-herb paste, ketchup, salad dressing and other food.

What product can it produce?

The liquid mixer with homogenizer is mainly used for the production of liquid soap, shampoo, laundry detergent, shower gel, hand wash, sauce, ketchup, dish washing soap,body wash...

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery