Bottle Labeling Machines

Bottle Labeling Machine Solutions for Streamlined Production

Precision and Efficiency for Every Bottle

Ensure your products stand out on the shelves with YUANYANG's high-performance bottle labeling machines. Designed for optimal efficiency, our label applicators guarantee fast, precise label placement on bottles of all shapes and sizes, helping YUANYANG maintain a professional and consistent image.

Features of YUANYANG Bottle Labeling Machines

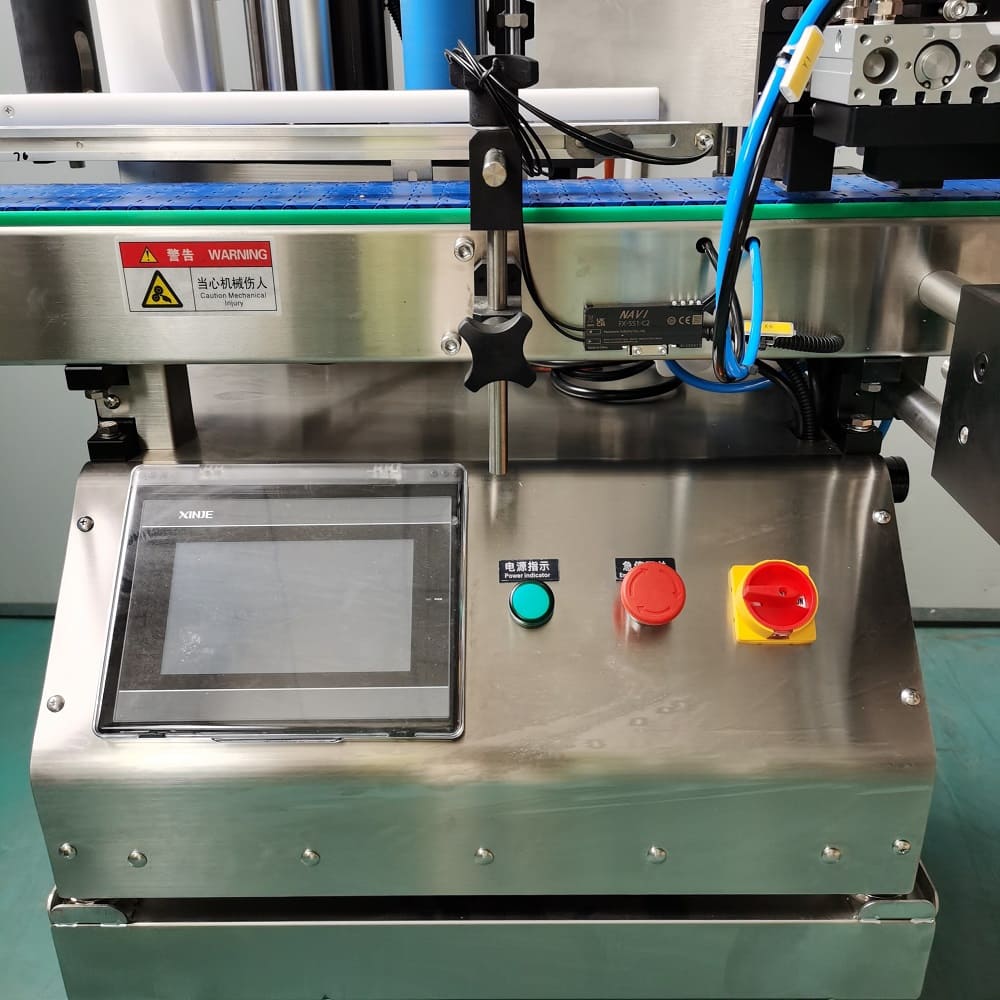

Our bottle labeling machines offer a range of advanced features, including automatic alignment, high-speed operation, and compatibility with different label types and bottle materials. The intuitive interface makes setup and operation easy for any production line, minimizing downtime and boosting productivity.

Seamless Integration with Turnkey Production Lines

As a leading China-based manufacturer, YUANYANG provides complete support for integrating our bottle labeling machines into your existing production line. Our comprehensive turnkey services include free technical training and expert installation, ensuring your facility operates at peak efficiency from day one.

Reliability and CE-Certified Quality

All YUANYANG machines, including our bottle labeling equipment, are built to the highest safety and reliability standards. With multiple CE certifications, you can trust that our solutions meet stringent European requirements, ensuring operational safety and compliance.

Choose YUANYANG for Your Bottle Labeling Needs

Since 2008, YUANYANG has been committed to supporting diverse industries with reliable mixing and packaging solutions, including bottle labeling machines. Trust our expertise to deliver equipment that enhances your product’s appeal, streamlines labeling, and grows your bottom line.

*Upgrade your production with YUANYANG bottle labeling machines—where quality, efficiency, and support come standard.*

bottle labeling machine Display

Can you customized contact materials stainless steel 316L for the detergent powder making machine ?

Yes, we provide customization service upon requirements. The contact parts can be SUS304 or SUS316L. But the cost will be more.

How to adjust the filling weight?

There is weight regulator for client to refer. Just adjust several times until you get the accurate filling weight. Remember the reference number, next time directly use for the same materials and bottles.

How extensive is your global after-sales support network?

We have a global after-sales support network that covers multiple regions to ensure that customers can receive quick responses no matter where they are located.

Does Yuanyang’s pharmaceutical equipment comply with GMP standards?

Yes, all of Yuanyang’s pharmaceutical equipment complies with Good Manufacturing Practice (GMP) standards, ensuring quality and hygiene at every production stage, meeting the requirements of global pharmaceutical regulatory agencies.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery