YUANYANG Vacuum Homogeneous Mixers: Precision Blending for Superior Products

YUANYANG Vacuum Homogeneous Mixers: Precision Blending for Superior Products

In demanding industries such as pharmaceuticals, cosmetics, and food, achieving perfect product consistency and stability is paramount. Air entrapment and inadequate mixing can lead to compromised quality, reduced shelf life, and aesthetic imperfections. The solution lies in precision engineering and advanced technology. YUANYANG, a leading manufacturer of industrial mixers and agitators in China since 2008, offers state-of-the-art vacuum homogeneous mixers engineered to deliver unparalleled consistency and stability for your most critical formulations.

Why Choose YUANYANG Vacuum Homogeneous Mixers?

YUANYANG's vacuum homogeneous mixers stand at the forefront of mixing technology, designed to overcome common production challenges. By combining powerful high shear mixing with a controlled vacuum environment, our machines effectively eliminate air bubbles, preventing oxidation and ensuring a perfectly smooth, uniform product. This results in enhanced stability, extended shelf life, and superior aesthetic appeal for your emulsions, suspensions, and gels. Each YUANYANG mixer is built for robust performance and adheres to the highest quality standards, proudly backed by multiple CE certifications – a testament to our unwavering commitment to safety and health for the European market.

Unmatched Performance Across Diverse Industries

From delicate pharmaceutical compounds and rich cosmetic creams to viscous food products and fine chemicals, YUANYANG's vacuum homogeneous mixers are versatile workhorses. They excel in creating stable emulsions, fine dispersions, and uniform suspensions required in industries where product integrity is non-negotiable. Our specialized designs, including vacuum emulsifying mixers, ensure optimal particle size reduction and thorough mixing, crucial for achieving critical product specifications every time. Whether you need to process lotions, sauces, ointments, or chemical slurries, our mixers provide the precision and reliability you can depend on.

Comprehensive Solutions & Unwavering Support

At YUANYANG, we understand that a mixer is often part of a larger ecosystem. That's why, since 2008, we've focused on providing complete production line equipment. Beyond our cutting-edge vacuum homogeneous mixers, we offer integrated solutions including storage tanks, filling machines, capping machines, labeling machines, and water treatment equipment. Our commitment extends beyond machinery; we offer free technical training and one-stop installation support, providing a full set of turnkey services to ensure your operations run seamlessly from day one. Partner with YUANYANG, a brand driven by the vision to become the best industrial mixer and agitator manufacturer in the world, and experience the pinnacle of mixing technology and support. Visit www.yuanymachinery.com to explore our comprehensive range of industrial mixing equipment.

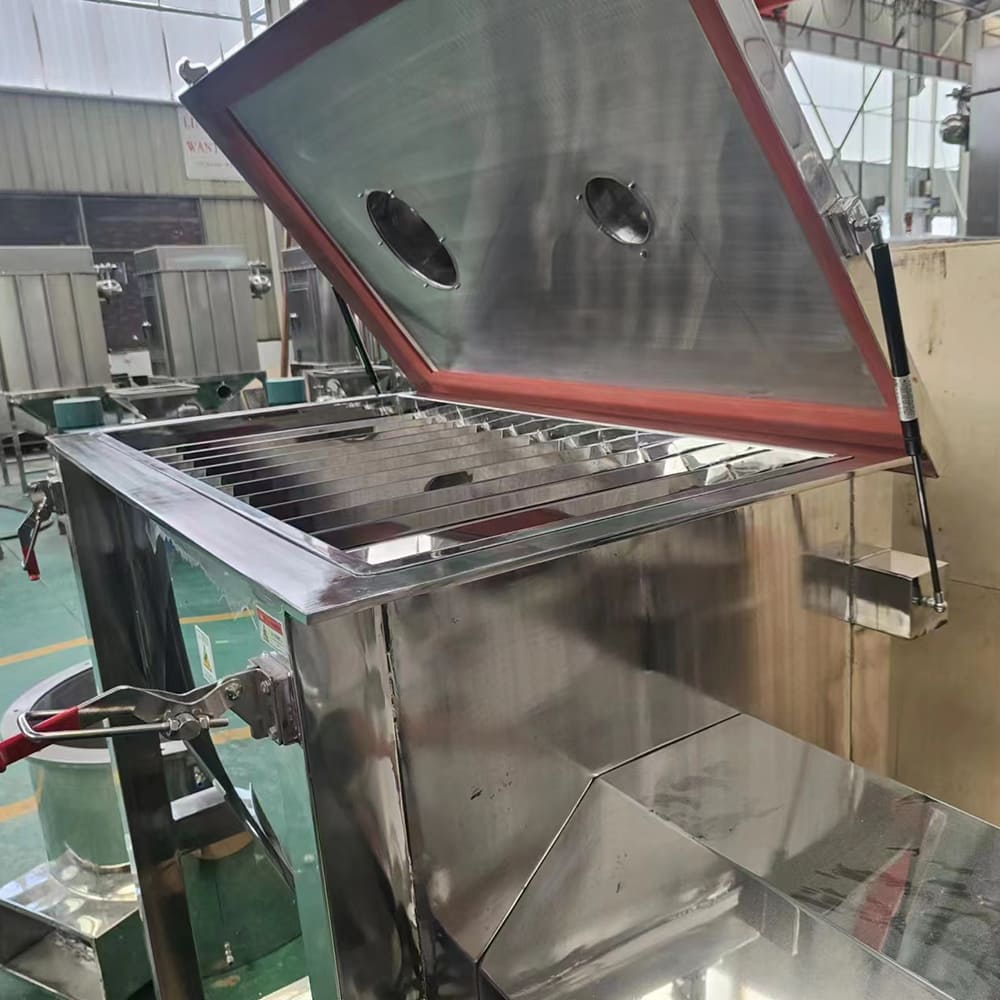

vacuum homogeneous mixer Display

Does your equipment support automated production?

Yes. Our equipment is highly automated, capable of full automation from ingredient preparation, mixing, emulsifying to filling and sealing, greatly reducing manual intervention and increasing production efficiency.

What capacity do you have about liquid tanks?

The capacity is from 50L - 5000L, can be customized according to space.

I want to connect the melting tank with my filling machine, can you help to customize the height to 70cm and provide adapters?

Yes, we would like to help give solutions according to actual situation. Yuany is a professional solution provider. Purchasing machines from Yuany not only saves cost but also saves energy and time.

Can you add load cell for material weighing for the ribbon mixer machine?

Yes, load cell is an optional choice. It is usually installed on feet. And there will be indicator on the control panel.

Can I customize the equipment to meet specific production needs?

Absolutely. Yuanyang offers customized equipment solutions, adjusting the functionality, size, or processes based on your production requirements to meet your unique needs.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery