High Quality Can Sealing Machines

# High-Quality Can Sealing Machines for Industrial Efficiency

Why Choose YUANYANG Can Sealing Machines?

YUANYANG is a trusted manufacturer of industrial sealing solutions, including can sealing machines designed for durability and precision. Our machines ensure airtight seals, extending product shelf life while maintaining hygiene and safety standards. With CE certification, our equipment meets EU regulatory requirements, making them ideal for food, beverage, and chemical industries.

Key Features of Our Can Sealing Machines

- Robust Construction: Made from high-grade stainless steel for corrosion resistance.

- High-Speed Sealing: Optimized for production lines, ensuring efficiency.

- Adjustable Settings: Customizable for different can sizes and materials.

- Easy Maintenance: User-friendly design for quick cleaning and servicing.

Applications Across Industries

Our can sealing machines are widely used in:

- Food & Beverage: Ensures freshness and compliance with safety standards.

- Pharmaceuticals: Maintains sterility for sensitive products.

- Chemicals: Prevents leaks and contamination in hazardous materials.

One-Stop Industrial Sealing Solutions

YUANYANG provides complete production line integration, including mixing, filling, capping, and sealing machines. Our turnkey services include free technical training and installation support, ensuring seamless operation.

Global Standards, Reliable Performance

With CE certification, our can sealing machines meet international safety and efficiency benchmarks. Trust YUANYANG for high-performance sealing solutions that enhance productivity.

Upgrade your production line today—(https://www.yuanymachinery.com/) for a customized quote!

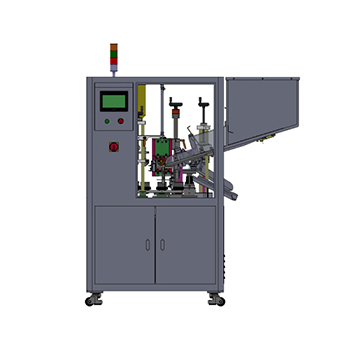

can sealing machine Display

Can I buy spare parts of heater tubes in case the heater burns?

Yes, we supply spare heating tubes. Client just remember the heater can not be operated without liquids in the jacket, otherwise, the heating tube will burn.

What’s the weight range can the automatic liquid packing machine pack?

Filling weight of this auto plastic packing machine should be less than 100g for this model. There will be different model for 100-500g or 500-1000g.

Can you also provide the related production machines?

Yes, we supply the complete set of liquid soap production machines, such as filling machine,capping machine,labeling machine,sealing machine, and coding machine.

Can the packaging machine for powder pack different weight in one machine?

Yes, the filling weight is adjustable with certain range. Client should tell the estimated filling weight to confirm. Different filling range may require different auger size.

Is the sachet packing machine equipped with a feeder also?

The standard quote is not included with a feeder, but we can add a feeder especially for the bag packaging machine if client need.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery