YUANYANG Cup Sealing Machines: Precision & Reliability for Perfect Packaging

YUANYANG Cup Sealing Machines: Precision & Reliability for Perfect Packaging

In today's fast-paced market, the integrity and presentation of your products are paramount. For items packaged in cups, a reliable and hygienic seal is not just an advantage—it's a necessity. At YUANYANG, while we are renowned as a leading manufacturer of industrial mixers and agitators, our expertise extends to providing comprehensive, end-to-end production line equipment, including state-of-the-art cup sealing machines. We understand that a seamless packaging process is crucial for product quality and consumer trust.

Why Choose YUANYANG Cup Sealing Machines?

YUANYANG's commitment to excellence, honed since 2008, is reflected in every piece of equipment we offer. Our cup sealing machines are engineered for precision, efficiency, and durability, ensuring your products are perfectly sealed every time. Here's what sets us apart:

- Uncompromising Quality & Hygiene: Designed with food-grade materials and meticulous engineering, our sealers ensure optimal hygiene, protecting your products from contamination.

- Robust Performance: Built to withstand continuous industrial operation, YUANYANG cup sealers deliver consistent, high-speed performance, minimizing downtime and maximizing output.

- Versatility: Whether you're sealing liquids, semi-solids, or granular products, our machines are adaptable to various cup sizes, materials, and sealing films, offering flexible packaging solutions.

- CE Certified: Adhering to strict European safety and health standards, our CE-certified equipment provides peace of mind regarding operational safety and compliance.

Diverse Solutions for Every Need

At YUANYANG, we offer a range of cup sealing machine models to perfectly match your production scale and specific requirements. From compact units ideal for smaller operations to fully automatic systems integrated into large-scale production lines, we have a solution for you. Our range includes:

- Manual Cup Sealing Machines: Perfect for small businesses, cafes, and testing environments, offering ease of use and cost-effectiveness.

- Semi-Automatic Cup Sealing Machines: A step up in automation, ideal for growing businesses seeking higher output with operator assistance.

- Automatic Cup Sealing Machines: Designed for high-volume production, these machines integrate seamlessly into complete packaging lines, providing maximum efficiency and minimal human intervention.

Our packaging solutions are trusted across various industries, including dairy, beverages, desserts, sauces, and more, ensuring secure sealing that preserves freshness and extends shelf life.

Seamless Integration & high quality Support

Choosing YUANYANG means opting for more than just a machine; it means partnering with a provider of complete production line equipment. Our cup sealing machines are designed to integrate flawlessly with other components of your line, from filling machines to labeling and inkjet printers. We pride ourselves on offering:

- Turnkey Services: From initial consultation to final commissioning, we provide a full suite of services, simplifying your procurement process.

- Free Technical Training: Ensure your team is proficient with our equipment through complimentary, expert-led training.

- One-Stop Installation Support: Our dedicated technicians provide seamless installation, getting your operations up and running efficiently.

Partner with YUANYANG for Packaging Excellence

As we strive to become the best industrial mixer and agitator manufacturer in the world, our dedication to quality and customer satisfaction extends to all our product offerings, including our advanced cup sealing machines. Partner with YUANYANG for reliable, efficient, and hygienic packaging solutions that elevate YUANYANG. Explore our full range of industrial equipment and discover how we can optimize your production line.

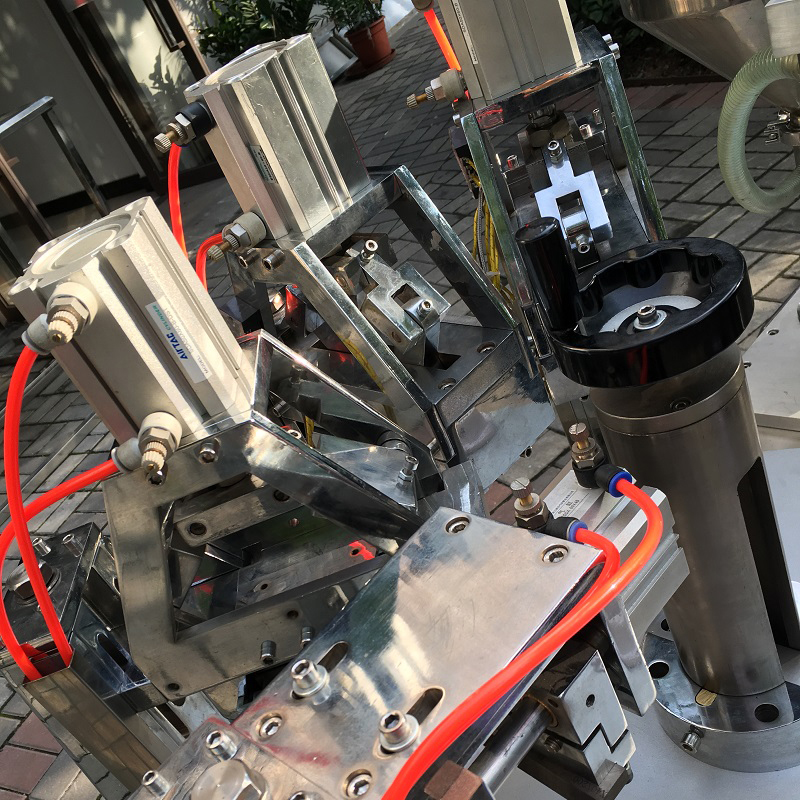

cup sealing machine Display

How to cool down fast? When the products is finished,the temperature is high, it takes a long time to get back to room temperature!

⦁The fast way is by using an external chiller to convey the cooling medium (usually cold water) through the pipe into the inner jacket,through water-circulation system to cool;

⦁Another way is directly continuously taking cooling medium (usually tap water) into the inner jacket of the agitator tank from inlet, and drain it from outlet to take away the heat.

What types of packaging does the equipment support?

Our machines accommodate various packaging formats, including bottles, bags, and small packs, to meet diverse market demands.

Can you explain the difference between homogenizer mixing tank and agitator mixing tank?

Homogenizer mixer is also called high shear mixer, whose core function is micronization and homogenization. The homogenization process enables the dispersion size in the suspension or emulsion to be micron fine particles by mechanical force of rotor and stator, thereby improving the stability and uniformity of the product.

The agitator mixing tank is just with normal blending function, just mix different materials together, but can’t mix two incompatible liquids together.

Is the powder packing machine suitable for different film size?

The standard sachet packing machine for powders is only suitable for one film size, and module must be customized according to the film width. But client can require more set of module to replace for different film width.

Is the complete set with a conveyor for finished packages?

Yes, the standard auger packing machine is equipped with a conveyor to convey finished packages to other machines?

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery