Achieve Unmatched Precision & Efficiency with YUANYANG High Shear Mixers & Homogenizers

In today's competitive manufacturing landscape, achieving perfect product consistency, stability, and texture is paramount. For industries ranging from pharmaceuticals and cosmetics to food and chemicals, this precision is often delivered by advanced mixing technology. YUANYANG, a leading manufacturer of industrial mixers and agitators in China since 2008, proudly presents its state-of-the-art high shear mixers and homogenizers – engineered to meet and exceed these demanding requirements.

Achieve Unmatched Precision & Efficiency with YUANYANG High Shear Mixers & Homogenizers

Understanding High Shear Mixing & Homogenization

High shear mixers and homogenizers are critical tools designed to rapidly blend, emulsify, disperse, and dissolve ingredients with unparalleled intensity. Unlike conventional agitators, these sophisticated machines employ a rotor-stator mechanism that generates high shear forces, hydraulic shear, and cavitation. This powerful action effectively reduces particle sizes, creates stable emulsions, and ensures uniform ingredient distribution, leading to a superior, consistent, and aesthetically pleasing final product. From creating stable lotions and creams to perfectly smooth sauces or consistent chemical suspensions, their ability to transform raw materials into high-quality finished goods is indispensable.

YUANYANG's Superior High Shear Technology

At YUANYANG, our commitment to innovation and quality is reflected in every high shear mixer and homogenizer we produce. As one of China's premier manufacturers, our expertise since 2008 has been focused on delivering robust, efficient, and reliable mixing solutions. Our range includes advanced vacuum homogenizers and high shear mixers, all meticulously designed to provide exceptional performance and longevity. We understand the nuances of various applications, ensuring our equipment precisely meets your process needs. Furthermore, YUANYANG's products proudly carry CE certification, a testament to our adherence to stringent European safety and health standards, giving you peace of mind regarding operational reliability.

Versatile Applications Across Diverse Industries

The versatility of YUANYANG's high shear mixers and homogenizers makes them indispensable across a multitude of sectors. In the cosmetic industry, they create stable emulsions for creams, lotions, and makeup. For pharmaceuticals, they ensure uniform dispersion of active ingredients in suspensions and ointments. The food and beverage sector relies on them for smooth sauces, dressings, dairy products, and fruit purees. Even in the chemical industry, our mixers are vital for producing consistent paints, coatings, and adhesives. Whatever your specific application, YUANYANG has the expertise and equipment to elevate your production quality.

The YUANYANG Advantage: Complete Turnkey Solutions

Beyond our advanced high shear mixers, YUANYANG distinguishes itself by offering comprehensive, end-to-end production line equipment. Since 2008, our focus has been on providing a seamless experience, from mixing equipment and storage tanks to filling, capping, labeling, and sealing machines, even including water treatment. We offer free technical training and one-stop installation support, ensuring a full set of turnkey services. This integrated approach not only simplifies your procurement process but also guarantees optimal compatibility and efficiency across your entire manufacturing operation.

Partner with YUANYANG for Future-Proof Mixing Solutions

YUANYANG's vision is to become the best industrial mixer and agitator manufacturer in the world. By choosing YUANYANG, you are partnering with a company dedicated to delivering excellence, innovation, and unparalleled customer support. Experience the difference that precision engineering and a complete solution provider can make to your production line. Explore our full range of high shear mixers and homogenizers and other industrial equipment on our website today.

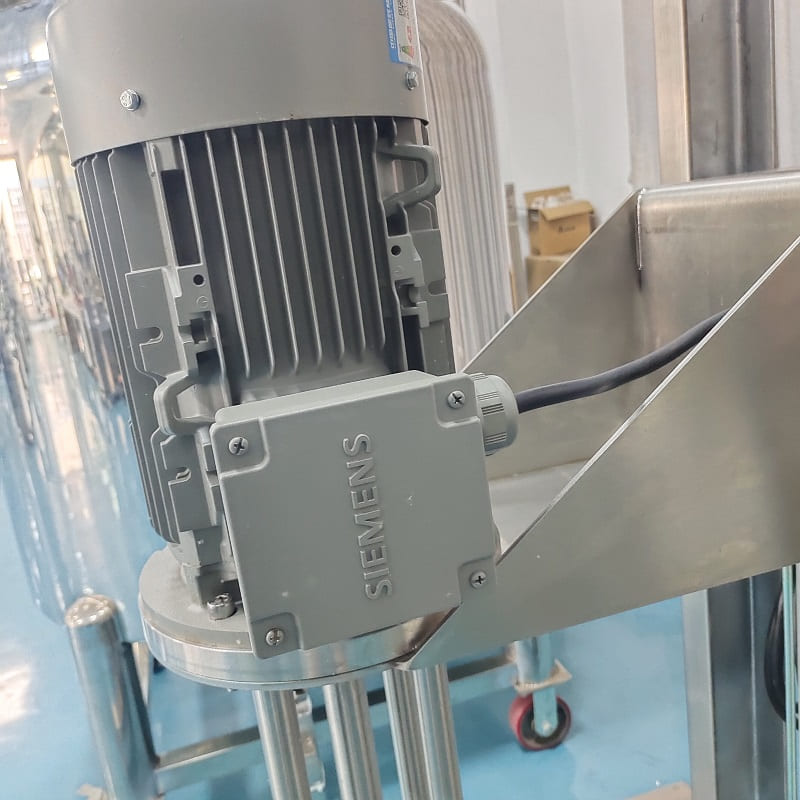

high shear mixer and homogenizer Display

What’s the feature of water tank and oil tank?

The water tank and oil tank are for pre-treatment for better mixing efficient when sucked into main emulsifying tank. The two tanks are often equipped with bottom dispersing plate or top mixing and double jackets for heating and insulation.

How to dry the mixed powder?

If the raw powder is not dry, and client wants to dry it during mixing, a jacket will be added with heater to achieve drying purpose.

Can each nozzle be controlled separately?

Yes, each nozzle can be controlled separately.

Do you have installation videos for the auger feeding machine?

Yes, we have installation videos for client to refer, which is quite easy to install.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery