YUANYANG Lab Vacuum Emulsifying Mixer – Precision and Efficiency in One Solution

YUANYANG Lab Vacuum Emulsifying Mixer – Unmatched Quality and Performance

Advanced Technology for Laboratory Applications

The YUANYANG lab vacuum emulsifying mixer is engineered to deliver precise blending and emulsification for demanding laboratory processes. By integrating vacuum technology with high-shear mixing, it ensures uniform particle size reduction, enhanced product stability, and prevention of air entrapment, essential for cosmetics, pharmaceuticals, and chemical formulations.

Comprehensive Features Ensuring Superior Results

This mixer features a robust vacuum system combined with a high-speed homogenizer, enabling efficient mixing under reduced pressure. The multifunctional design allows emulsification, homogenization, dispersion, and mixing in a single unit, saving time and improving product quality. User-friendly controls and durable components make it an industry favorite for research and small batch production.

YUANYANG’s Commitment to Customer Success

As a leading industrial mixer manufacturer since 2008, YUANYANG offers free technical training, professional installation support, and complete turnkey solutions. Our equipment complies with CE safety standards, guaranteeing reliable and safe operation. We aim to empower your production with cutting-edge technology and expert service backed by years of experience.

Why Choose YUANYANG Lab Vacuum Emulsifying Mixer?

- Precision vacuum homogenization and emulsification

- High shear mixing for consistent particle size

- CE certified for safety and compliance

- One-stop turnkey support including training and installation

- Ideal for pharmaceuticals, cosmetics, and chemical labs

Explore more about our lab vacuum emulsifying mixers and other industrial mixing solutions at YUANYANG official website.

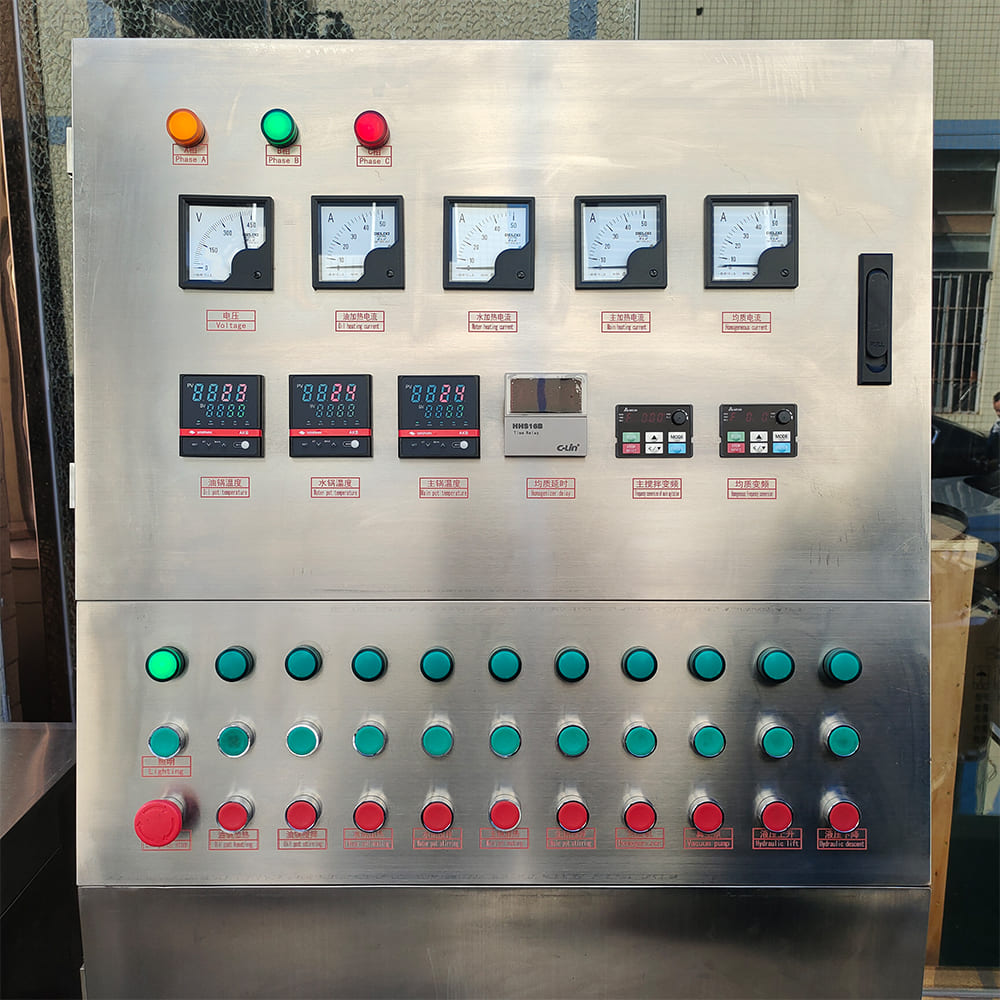

lab vacuum emulsifying mixer Display

Can you customize the nozzle size to fit my different container?

Yes, we customize nozzle for clients according specific packages.

I want to connect the melting tank with my filling machine, can you help to customize the height to 70cm and provide adapters?

Yes, we would like to help give solutions according to actual situation. Yuany is a professional solution provider. Purchasing machines from Yuany not only saves cost but also saves energy and time.

What’s the maximum and minimum height can the automatic sealing machine lift up and go down?

The maximum height for the sealing head to the floor is 75-120cm.

What material can the piston filling machine fill?

The piston filler can fill a variety of viscous liquids and pastes, such as laundry detergent, shampoo, hair conditioner, toothpaste, gel water, aloe vera gel, lotion and other washing and care products, honey, loquat paste, mother-herb paste, ketchup, salad dressing and other food.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery