Inline Homogenizer Pumps | High-Performance Mixing Solutions by YUANYANG

Inline Homogenizer Pumps for Industrial Excellence

What Is an Inline Homogenizer Pump?

An inline homogenizer pump is a high-shear mixing device designed for continuous processing of liquids, emulsions, and suspensions. YUANYANG's pumps ensure uniform particle size reduction and superior product consistency, ideal for industries like pharmaceuticals, cosmetics, and food processing.

Why Choose YUANYANG’s Inline Homogenizer Pumps?

YUANYANG delivers cutting-edge inline homogenizer pumps with CE certification, ensuring safety and compliance. Our pumps feature robust construction, energy efficiency, and easy integration into production lines, backed by free technical training and turnkey services.

Applications of Inline Homogenizer Pumps

From emulsifying creams to dispersing nanoparticles, YUANYANG’s inline homogenizer pumps excel in diverse applications. They are widely used in chemical processing, dairy production, and cosmetic manufacturing for seamless, high-quality mixing.

Custom Solutions and Support

YUANYANG offers tailored inline homogenizer pump solutions to meet specific production needs. Our team provides one-stop installation, maintenance, and 24/7 support to maximize uptime and performance.

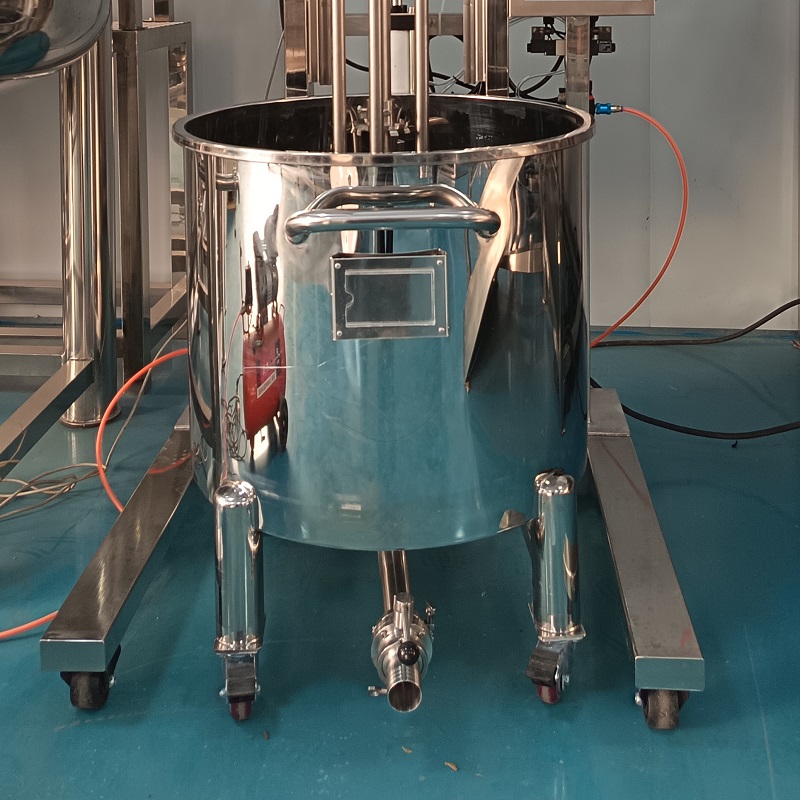

inline homogenizer pump Display

Is there any safety devices for the homogenizer tank?

Yes,there are safety valves for jacket pressure and vacuum pressure. When the pressure reaches the designed margin point, the safety valves can protect the machine by releasing the gas.

And circuit protection device is equipped in the control box, when the power supply of the factory is beyond the designed voltage of the machine, or occurs short circuit, it will operate self-protection system.

Do you also have conveyor for the bottle lid sealing machine?

Yes, we can add a conveyor for the bottle sealing machine. And customize the conveyor height according to requirement if need.

How do I know the water conductivity?

The reverse osmosis water filter machine can display both raw water conductivity and output water conductivity.

What types of chemical components does the equipment support?

The equipment can handle liquids, powders, granules, and other components, depending on the equipment model.

Can you provide custom service?

Definitely we offer customization service. For example, the thickness of layers, the brand of motor, the mixing types, the power of motor, power supply.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery