High Shear Homogenizer Mixer

# High Shear Homogenizer Mixer – Precision Mixing Solutions

What Is a High Shear Homogenizer Mixer?

A high shear homogenizer mixer is a powerful industrial mixing device designed to emulsify, disperse, and homogenize materials efficiently. Using high-speed rotors and stators, it ensures uniform particle size reduction, ideal for industries like pharmaceuticals, cosmetics, and food processing.

Key Benefits of YUANYANG High Shear Mixers

- Superior Homogenization: Achieves fine, consistent textures with rapid shear force.

- High Efficiency: Reduces processing time while improving product quality.

- Durable Construction: Made from high-grade stainless steel for longevity.

- CE-Certified: Compliant with EU safety and health standards.

Applications Across Industries

Pharmaceutical & Cosmetics

Ensures smooth, uniform formulations for creams, ointments, and lotions.

Food & Beverage

Perfect for sauces, dressings, and dairy products requiring fine emulsification.

Chemicals & Paints

Delivers stable suspensions and dispersions in coatings and adhesives.

Why Choose YUANYANG?

As a leading industrial mixer manufacturer since 2008, YUANYANG provides:

- Turnkey Solutions: Full production line support, from mixing to packaging.

- Free Technical Training: Expert guidance for seamless operation.

- Global Compliance: CE-certified equipment for international markets.

Upgrade Your Mixing Process Today

Explore YUANYANG’s high shear homogenizer mixers—engineered for performance, reliability, and efficiency. (https://www.yuanymachinery.com/) for more details!

This content is optimized for SEO with targeted keywords, clear s, and concise yet informative descriptions to enhance search rankings while maintaining readability.

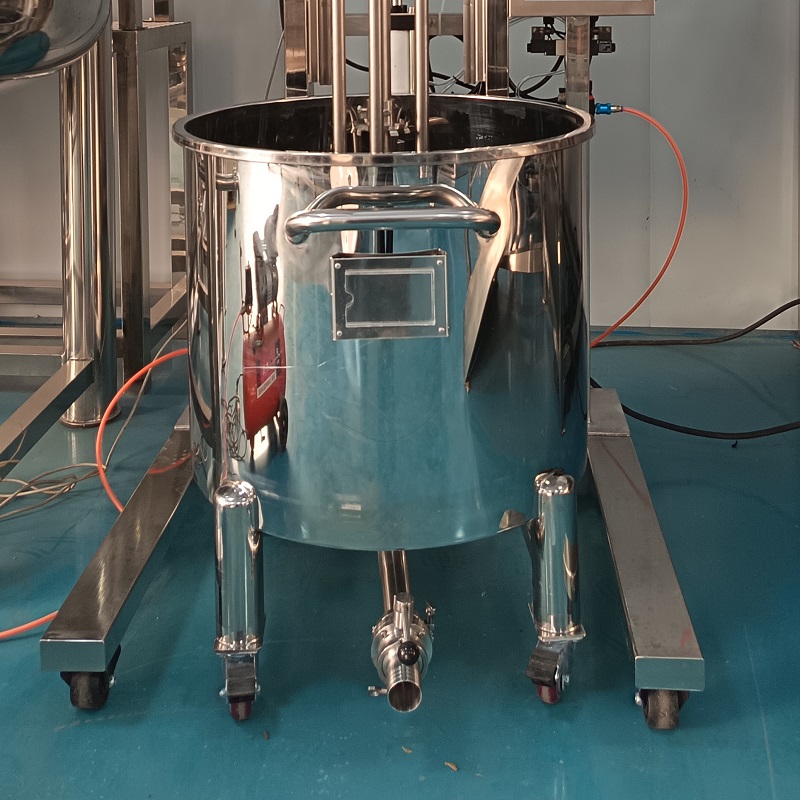

high shear homogenizer mixer Display

Does Yuanyang's equipment meet food hygiene standards?

Yes, all our equipment is made with materials that comply with food hygiene standards, ensuring the parts in contact with food are hygienic and prevent contamination.

Do you also have a machine for powder feeding?

Yes, we also manufacture powder feeder machine for the horizontal mixer machine. It is usually recommended the screw powder feeder type.

Can you add a mixing function for the tank with heater?

Sure, the cooling tank or heating tank can be customized with top mixing such as paddle, or frame, or scrapers. And client can choose a fixed speed 60rpm, or standard 0-60 rpm with speed adjustment, or customize other speed.

What’s the filling range of the powder dosing machine?

The filling range of the semi auto powder filling machines is: 10-5000g. But we need to customize according to specific weight that clients plan to pack. The screw model will be different.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery