Labeling Machine for Bottles

Labeling Machine for Bottles: Boost Your Packaging Line with YUANYANG

Precision Labeling for All Bottle Types

YUANYANG’s labeling machines for bottles are engineered for versatility and accuracy. Whether you’re labeling round, square, or uniquely shaped bottles, our equipment ensures consistent and professional results. Designed to handle glass, plastic, or metal bottles, our machines keep your production running smoothly and efficiently.

Automatic Solutions for Enhanced Efficiency

Streamline your operations with our automatic labeling machines for bottles. Equipped with advanced sensors and user-friendly controls, YUANYANG labelers dramatically reduce manual labor and minimize labeling errors. Integrate seamlessly into your existing production line for maximum automation and productivity.

Customizable and Easy to Operate

Choose from a range of configurations, including single-side, double-side, or wrap-around labeling. Our bottle labelers are customizable to suit your unique packaging needs and accommodate different bottle sizes. Easy-to-use touch screens allow for quick setup and adjustment, helping operators save time and reduce downtime.

Reliable Performance, Certified Safety

Since 2008, YUANYANG has built a reputation for reliable and durable machinery. Our labeling machines arrive CE-certified for operator safety and comply with international standards—providing peace of mind while you grow YUANYANG globally.

Complete Turnkey Support

As a customer-focused manufacturer, YUANYANG delivers more than quality equipment. We offer free technical training and comprehensive installation support for a hassle-free experience—making us your trusted partner from purchase to production.

Optimize your packaging and elevate YUANYANG with YUANYANG’s state-of-the-art labeling machine for bottles. Request your solution today!

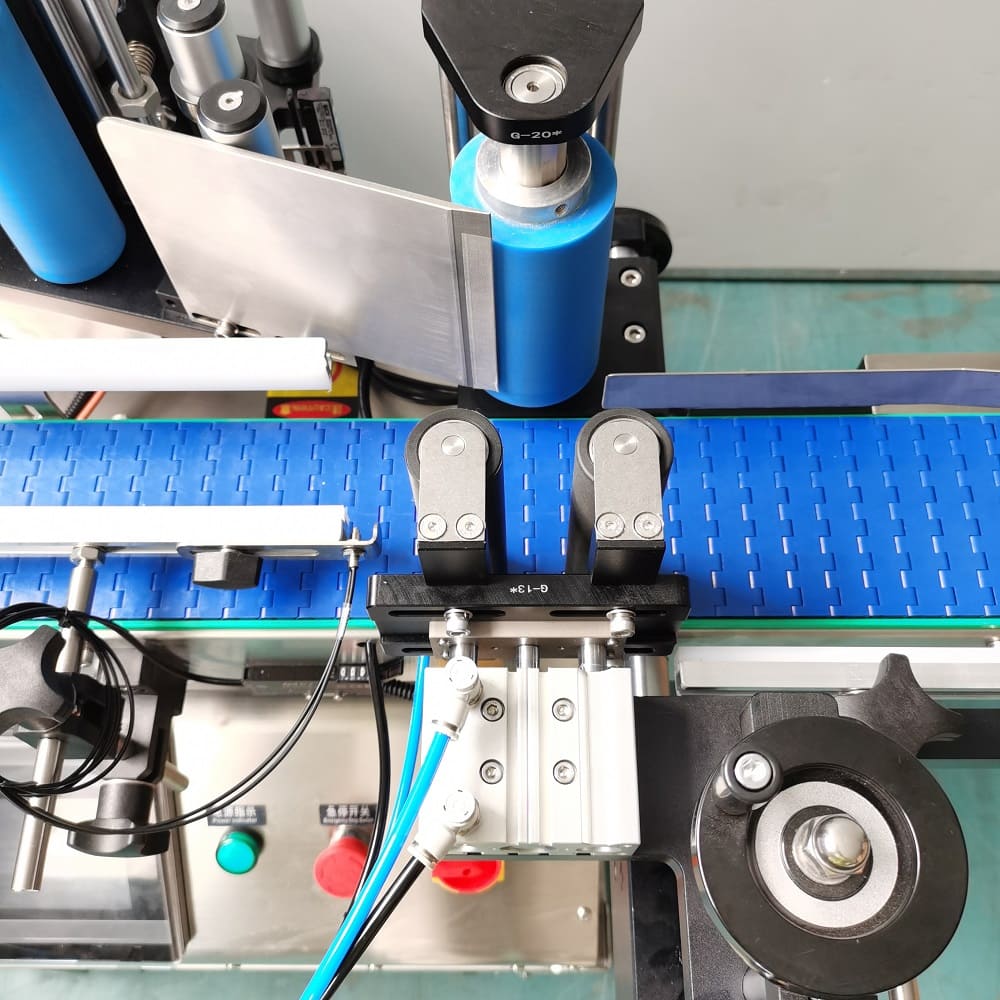

labeling machine for bottles Display

Why vacuum system is necessary?

In the mixing process of cosmetic emulsifier, it is necessary to eliminate bubbles and prevent oxidation to ensure the quality of the mixture.

In a vacuum environment, there are following advantages:

⦁ Improve mixing efficiency

In a vacuum environment, the surface area of the mixture increases, and the interaction force between the substances will also increase, thus speeding up the mixing speed.

⦁ Prevent oxidation

In a vacuum environment, oxygen cannot enter the mixture, so it can effectively prevent the oxidation of the mixture.

⦁ Reduce bubbles

In a vacuum environment, the bubbles in the mixture will be drawn out, so that you can get a bubble-free mixture.

Does Yuanyang’s pharmaceutical equipment comply with GMP standards?

Yes, all of Yuanyang’s pharmaceutical equipment complies with Good Manufacturing Practice (GMP) standards, ensuring quality and hygiene at every production stage, meeting the requirements of global pharmaceutical regulatory agencies.

Do you have PLC control panel for the soap mixing tank?

Yes, the control panel can be button control or with PLC touch screen. The standard is with button control, clients choose based on budget. we will customize upon requirements.

Do you have manual instructions for powder mixers?

Yes, we provide manual instruction of English version for clients as well as video test and operations for better understanding.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery