YUANYANG Omni Homogenizers: Mastering Precision Blending for Industrial Excellence

YUANYANG Omni Homogenizers: Mastering Precision Blending for Industrial Excellence

At YUANYANG, a leading manufacturer of industrial mixers and agitators since 2008, we understand that achieving perfect product consistency is paramount in today's competitive markets. Our advanced range of industrial mixers includes the innovative omni homogenizer, engineered to deliver unparalleled performance in homogenization, emulsification, and dispersion processes across diverse industries. With our commitment to quality, backed by multiple CE certifications, YUANYANG stands as your trusted partner for high-performance mixing solutions.

Unveiling the Power of Omni Homogenizers

An omni homogenizer is a versatile and robust industrial mixer designed for high-shear mixing, crucial for creating stable emulsions, fine dispersions, and uniform product textures. Unlike standard mixers, an omni homogenizer ensures intense shear forces, effectively reducing particle size, dissolving solids, and blending immiscible liquids into a homogeneous mixture. This capability is vital for products requiring a smooth consistency, extended shelf life, and enhanced aesthetic appeal, from pharmaceuticals and cosmetics to food and chemicals. YUANYANG's designs prioritize efficiency, reliability, and easy maintenance.

Why YUANYANG Leads in Homogenizer Technology

YUANYANG’s expertise in industrial mixers, including vacuum homogenizers and high shear mixers, translates directly into the superior performance of our omni homogenizer line. We leverage over a decade of experience to design equipment that not only meets but exceeds industry standards. Our products are crafted from High Quality materials, ensuring durability and compliance with strict hygiene regulations where applicable. Choosing YUANYANG means opting for precision engineering, energy efficiency, and a partner dedicated to your production success. Our CE certifications further underline our adherence to European safety, health, and environmental protection requirements, giving you peace of mind.

Applications Across Critical Industries

The versatility of YUANYANG’s omni homogenizer makes it an indispensable asset across a multitude of sectors. In the cosmetic industry, it's perfect for creating smooth creams, lotions, and makeup. For pharmaceuticals, it ensures uniform distribution of active ingredients in suspensions and emulsions. The food industry benefits from its ability to produce consistent sauces, dairy products, and beverages. Furthermore, our homogenizers are ideal for chemical processes requiring stable dispersions and precise particle size control, showcasing their adaptability and robust design for various challenging applications.

Comprehensive Support and Turnkey Solutions

At YUANYANG, we go beyond supplying world-class industrial mixers. We are committed to providing complete production line equipment, including mixing equipment, storage tanks, filling machines, and more. Our unique offering includes free technical training and one-stop installation support, delivering a full set of turnkey services. This comprehensive approach ensures seamless integration and optimal performance of your new omni homogenizer and related machinery, helping you achieve efficient and reliable production processes. Our vision is clear: to become the best industrial mixer and agitator manufacturer in the world, achieved by consistently delivering excellence and unparalleled customer support.

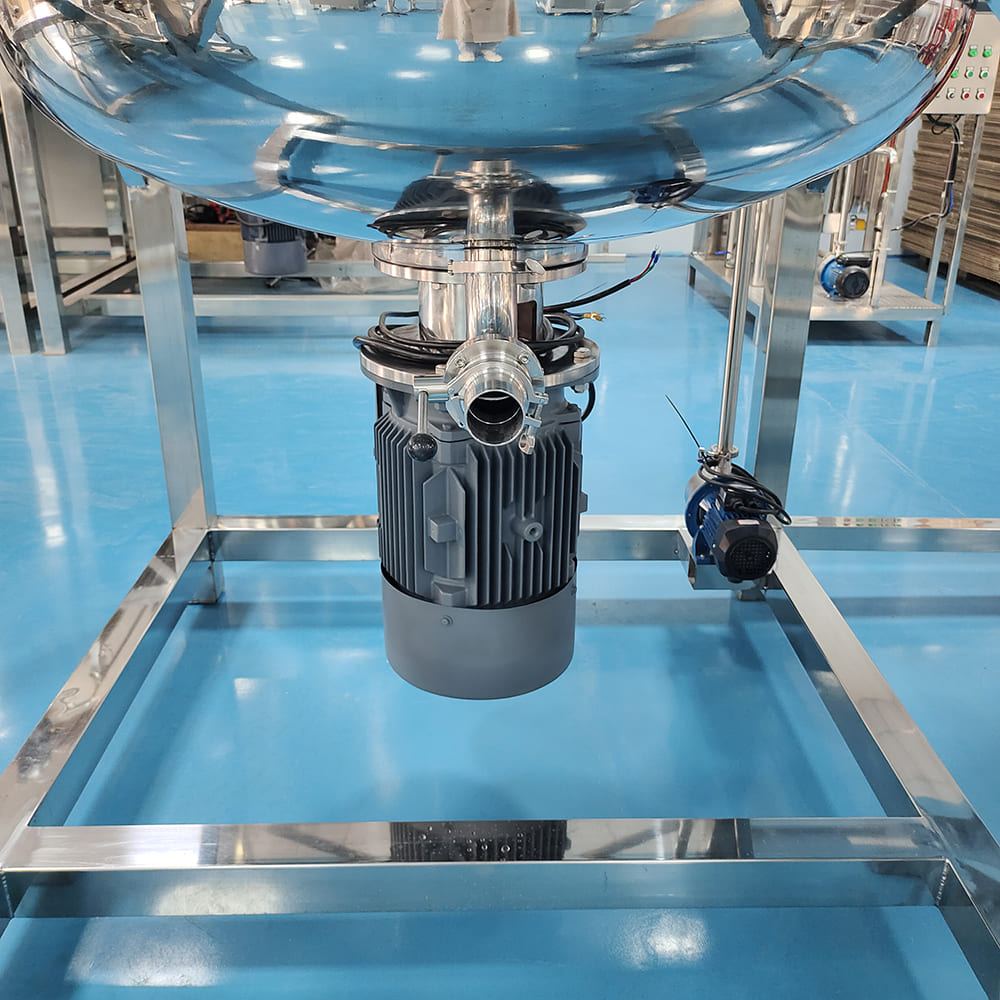

omni homogenizer Display

Can you make a bigger material hopper for the screw feeder machine?

Yes, the hopper capacity can be customized bigger according to needs.

How does the rotor and stator work?

When the equipment is running, the rotor drives the blade to rotate at a high speed, generating a strong centrifugal force field, and forming a negative pressure zone in the center of the rotor, which inhales the material liquid. Under the action of centrifugal force, the material spreads from the center to the four sides, and is subjected to the stirring and shearing action of the blades during the diffusion process. The material is subjected to further shearing action in the narrow gap between the end face of the blade and the inner side of the stator tooth ring, and then enters the narrow gap between the rotating tooth and the fixed tooth of the inner ring, and is affected by mechanical force and hydrodynamics effect, resulting in shearing, friction and impact, so that dispersed phase particles or droplets are broken. As the linear speed of the tooth is gradually increased from the inner ring to the outer ring, the crushing environment of the material is continuously improved, and the purpose of homogenizing emulsification is finally achieved.

Will do test for the machine I order before production?

Yes, every machine will be test and are assured without problems before packing. Therefore, clients will never worry about the quality. Only when clients are satisfied with the finished machine can we pack and ship.

Can you make the leg longer, I need a higher discharge outlet?

Yes, the tank legs length is customized as well as the discharge outlet height.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery