High-Quality Reverse Osmosis Water Treatment Equipment

Reverse Osmosis Water Treatment Equipment from YUANYANG

Efficient Water Purification for Every Industry

YUANYANG's reverse osmosis water treatment equipment delivers superior water purification, efficiently removing dissolved solids, contaminants, and impurities. Our advanced systems are designed for industrial applications, using cutting-edge reverse osmosis technology to ensure reliable, clean, and safe water.

Complete Selection of Reverse Osmosis Solutions

We provide a comprehensive range of reverse osmosis water treatment machines, custom-designed to meet different capacity needs and water quality standards. Whether you require a compact unit or a full-scale industrial system, YUANYANG offers tailored solutions for diverse water treatment challenges.

Outstanding Performance and Durability

Our RO equipment stands out for its exceptional durability and consistent performance. Constructed with high-grade materials and state-of-the-art membranes, YUANYANG's reverse osmosis water treatment plants are engineered for maximum efficiency and long-lasting use, minimizing maintenance needs and operational costs.

Professional Support and Turnkey Services

From system selection and installation to operation and technical support, YUANYANG provides complete, one-stop services, including free technical training. Our experienced team ensures smooth integration and optimal performance of your industrial water treatment system, enabling you to focus on your business goals.

Why Choose YUANYANG's Reverse Osmosis Water Treatment Equipment?

- CE-certified for safety and reliability

- Customizable solutions for any industry

- Outstanding after-sales support and training

- Over 15 years of industry expertise

Choose YUANYANG for high-quality reverse osmosis water treatment equipment that boosts productivity and guarantees water purity. Contact us today to discover the ideal solution for your water treatment requirements.

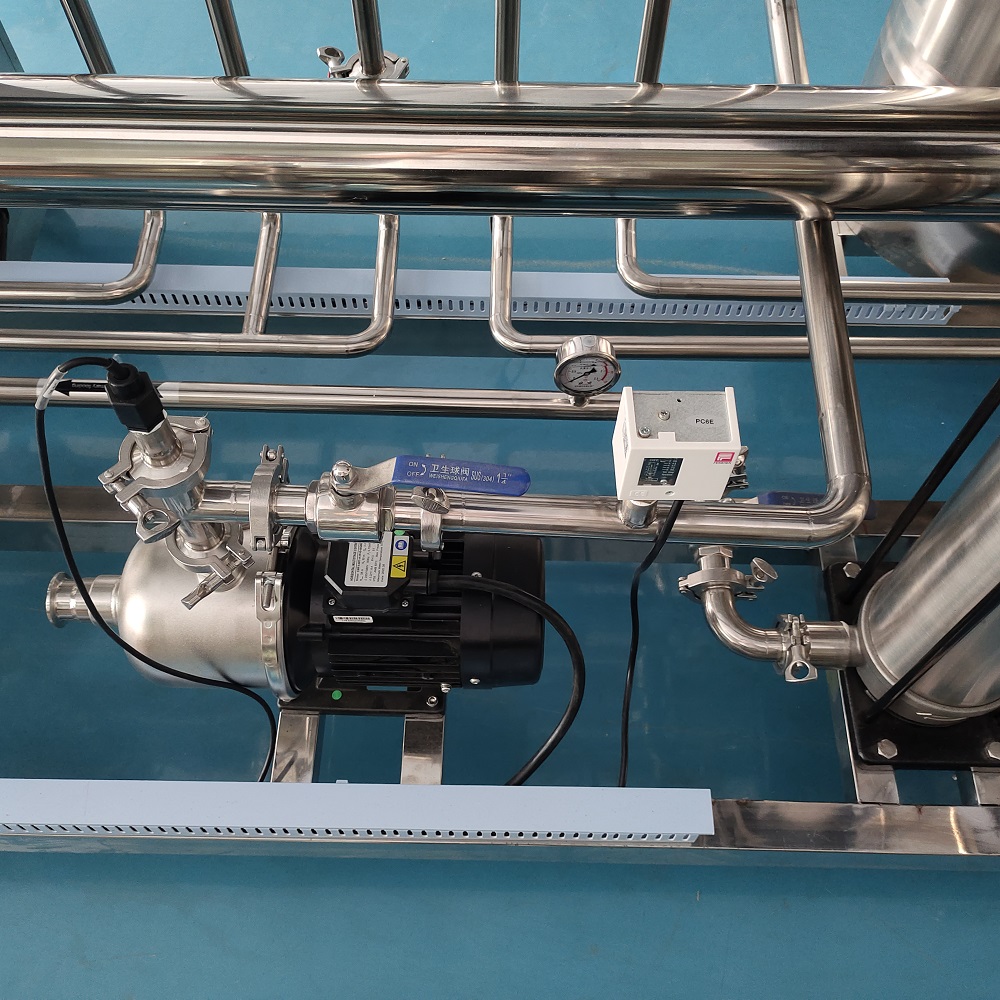

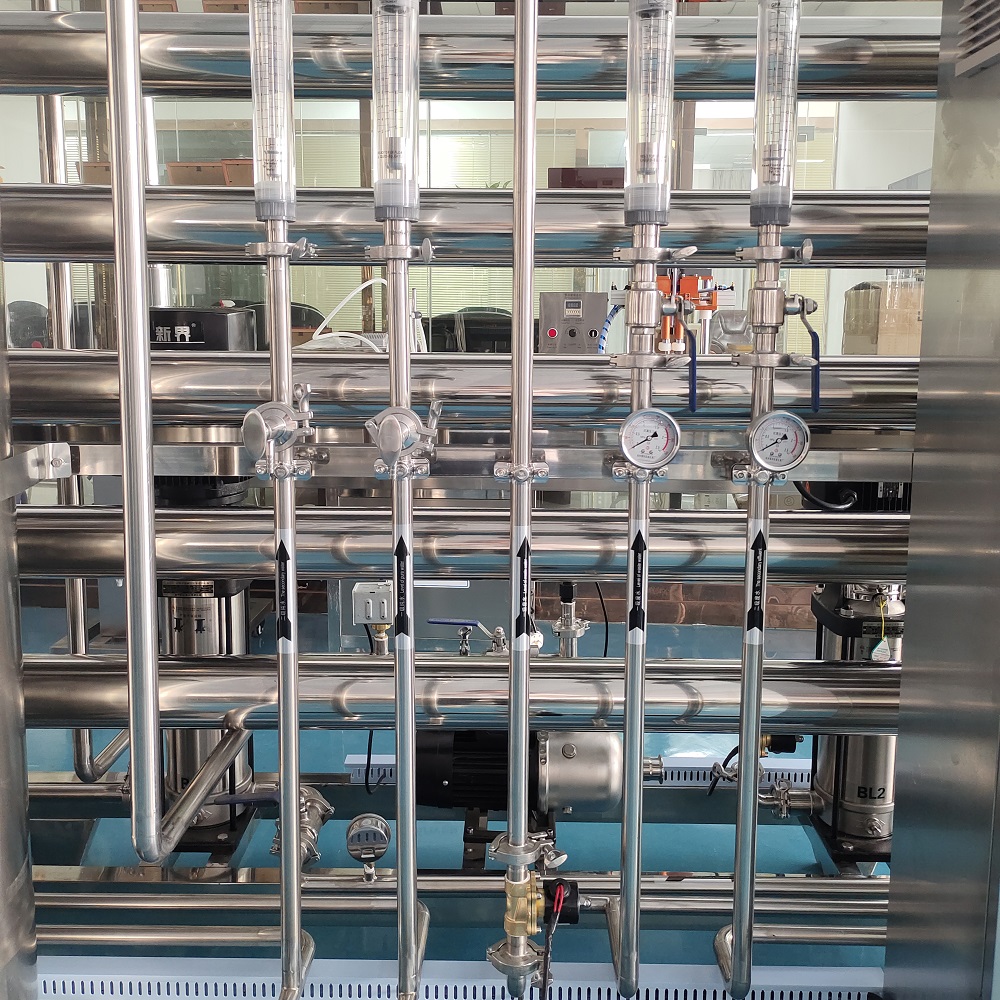

reverse osmosis water treatment equipment Display

What is the production capacity of the equipment?

Our equipment supports both small-batch and large-batch production, depending on customer needs. The equipment is highly scalable and can be adjusted according to your production scale.

Is the equipment compliant with environmental standards?

Yes, all our machines meet international environmental standards, reducing emissions and supporting sustainable production.

The power supply in my country is different, can you customize?

Yes, the power supply will be customized according to country. Clients should confirm with us before production.

What’s the distance between the bottle neck and sealing head for the best sealing effect?

Generally, the distance between cap and sealing device is no more than 5 mm, and for large diameter bottle,make the distance 8 mm. The longer distance, the weaker power becomes, the larger bottle,requires larger working power.

How is the quality?

We provide high-standard equipment. Quality is priority. People from Yuany always attach great importance to quality control from the beginning to the end. We support production inspection before shipment. And all machines will be tested and send you videos. You can also send your own packages/materials for rest-run after the machines are finished. Our factory has gained GMP,ISO,and CE Certificates.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery