Industrial Reverse Osmosis Water Treatment Solutions

Industrial Reverse Osmosis Water Treatment Solutions

Reliable Purification for Industrial Applications

YUANYANG offers advanced reverse osmosis industrial water treatment systems designed to deliver dependable and high-purity water for a variety of industrial uses. Our tailored solutions help manufacturers meet strict quality standards, reduce operational costs, and safeguard their equipment from scaling and corrosion.

Efficiency and Scalability for Every Project

Our reverse osmosis industrial water treatment solutions are engineered for maximum efficiency and scalability. Whether you require water purification for a single production line or an entire facility, YUANYANG provides systems that adapt to your growth and changing requirements, ensuring consistent water quality at every stage.

Advanced Technology for Superior Results

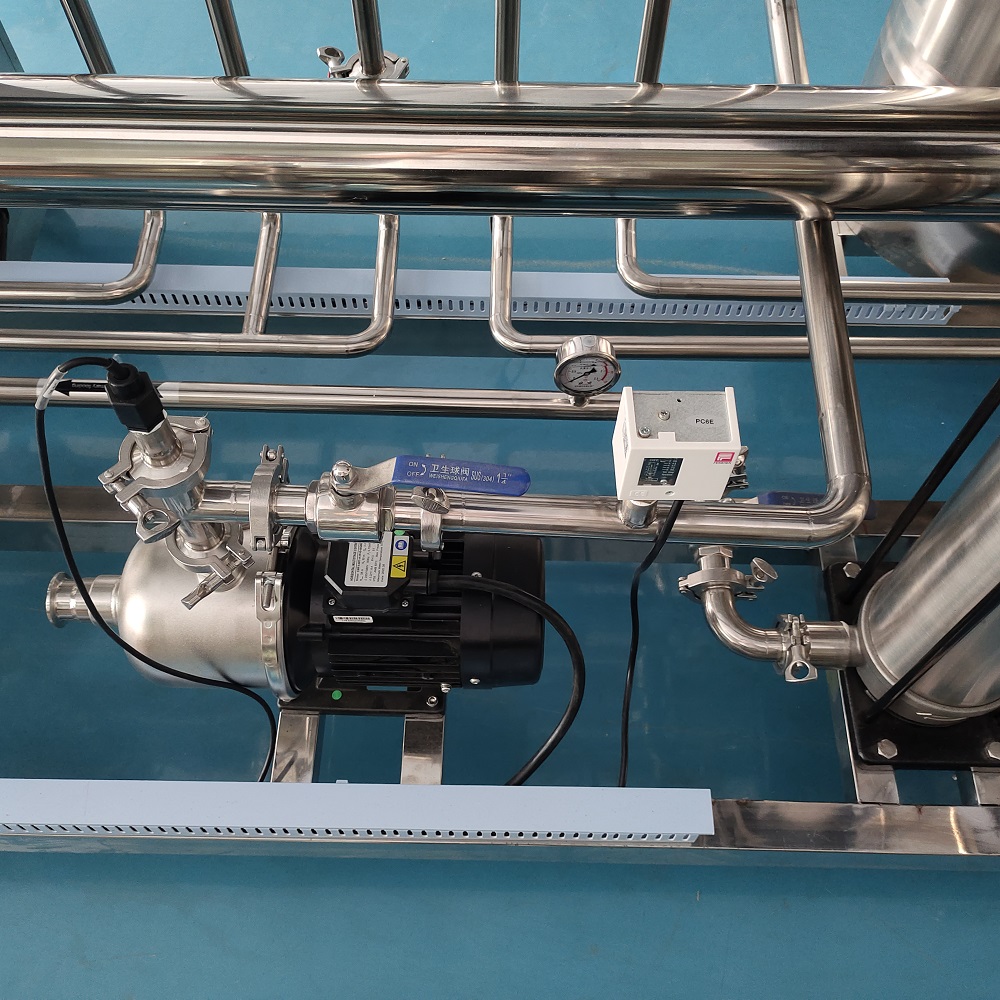

YUANYANG utilizes the latest membrane filtration and automation technologies to remove dissolved solids, bacteria, and other contaminants effectively. This guarantees water that not only meets but exceeds industry standards, improving production processes and end-product consistency.

One-Stop Service and Comprehensive Support

From selecting the right reverse osmosis system to installation, commissioning, and ongoing maintenance, YUANYANG delivers one-stop, turnkey water treatment solutions. Our experts provide free technical training and lifelong support, ensuring long-term reliability of your water treatment operation.

Certified Quality and Global Trust

Since 2008, YUANYANG has helped international manufacturers achieve outstanding water purity with CE-certified equipment and professional support. Our solutions are trusted by global brands across food, cosmetics, pharmaceuticals, and chemical industries.

Choose YUANYANG for reverse osmosis industrial water treatment and experience efficiency, reliability, and comprehensive lifelong support from China’s leading factory.

reverse osmosis industrial water treatment Display

How long does it take to produce the ribbon blender powder machines?

The leading time is about 20-30 days. To ensure quality, the ribbon powder mixer is worth the wait.

Do you offer customization services?

Yes, we support personalized design of equipment and adjustments based on specific customer needs.

Will do test for the machine I order before production?

Yes, every machine will be test and are assured without problems before packing. Therefore, clients will never worry about the quality. Only when clients are satisfied with the finished machine can we pack and ship.

Do you supply steam generator and provide steam and cooling pipes together for the mixing tank with homogenizer machine?

If the mixing tank is with steam heating, we will help to supply steam generator and provide steam and cooling pipes. But this is an optional choice. Client can prepare by steam generator by himself. The steam pipe is usually quoted separately.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery