Single Layer Homogenizer Mixing Tanks | YUANYANG

# Single Layer Homogenizer Mixing Tanks for Sale

High-Quality Mixing Solutions from YUANYANG

YUANYANG, a leading China-based manufacturer, offers superior single layer homogenizer mixing tanks designed for efficiency and reliability. Our tanks are built to exacting standards, using High Quality materials for long-lasting performance in various industries. We provide complete production line solutions, including supporting equipment.

Features & Benefits of Our Tanks

Our single layer homogenizer mixing tanks incorporate advanced homogenization technology to ensure thorough mixing and consistent product quality. Benefits include improved product texture, enhanced stability, and increased efficiency in your production process. Choose from various sizes to match your specific needs.

Why Choose YUANYANG?

With over 15 years of experience, YUANYANG is a trusted name in industrial mixing and blending equipment. We provide comprehensive support, including free technical training and turnkey installation services. Our CE certification assures compliance with stringent safety and health standards.

Complete Turnkey Solutions

Beyond our single layer homogenizer mixing tanks, YUANYANG offers a wide range of equipment including vacuum homogenizer mixers, emulsifying mixers, high shear mixers, filling and packaging machines, and water treatment systems. We handle everything from design to installation, providing a seamless and stress-free experience.

Contact Us Today

Ready to improve your production process? Contact YUANYANG today to discuss your specific requirements and receive a customized quote for a single layer homogenizer mixing tank. We are dedicated to providing top-tier equipment and unparalleled customer support.

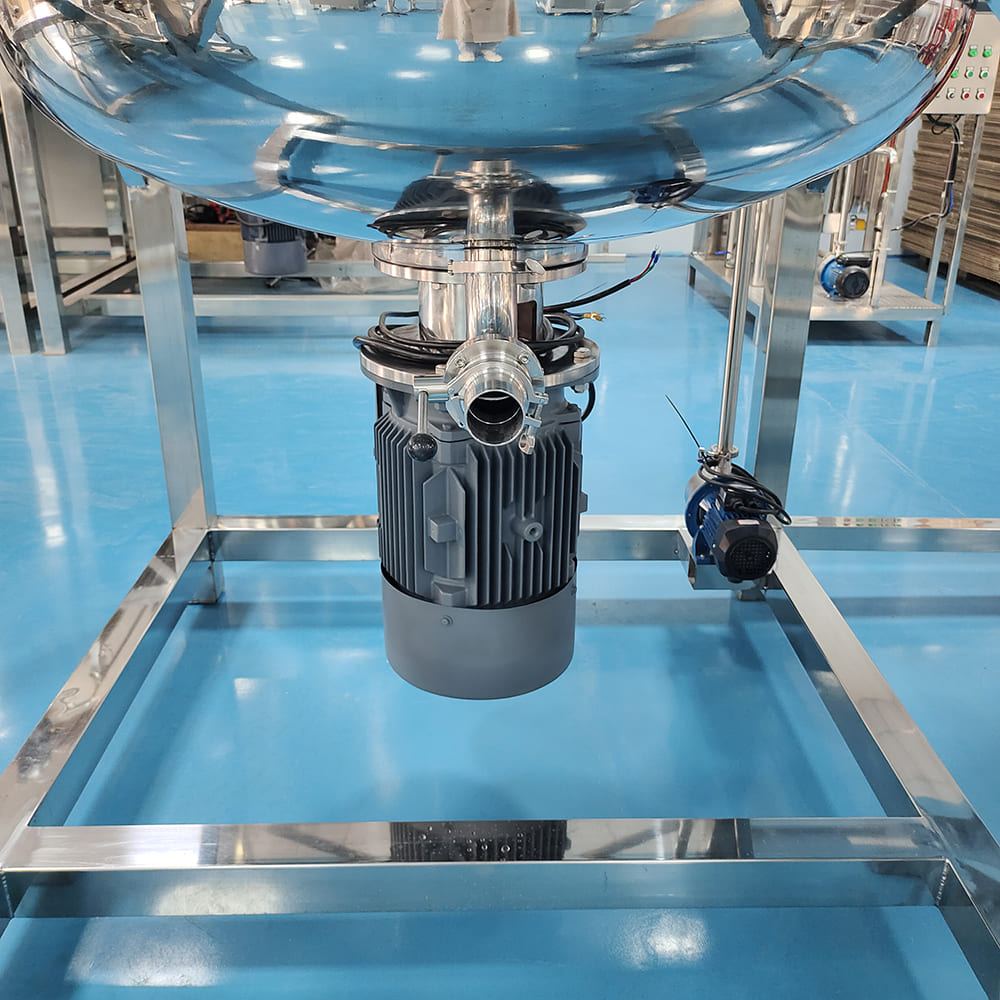

Single Layer Homogenizer Mixing Tank for sale Display

Is the servo capper be compatible for different bottle size and shapes?

Yes, the capping wheels can be adjusted higher or lower for different bottle height. The distance between wheels can be wider or closer for different cap diameter.

Can I use city water to produce liquid detergent?

As you know, water takes 70-99% proportion of raw materials for liquid detergent production. So the quality of water is quite important to produce qualified liquid cleaning products. The raw water should be treated before taking into tank.

How is installation and commissioning done?

We provide detailed written manuals and remote video guidance, or on-site installation and commissioning services to ensure the equipment is quickly operational.

Do you have temperature control system for the shampoo making machine?

Yes, there is temperature probe into tank at bottom. It detects temperature and display on the control panel. What’s more, the target temperature can be set.

Can this capping machine for bottles be connected with filling machine,or labeling machine?

Yes, if client already has an old automatic labeling machine, just tell the conveyor height, we will customize our capping machine height.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery