Two-Stage Water Treatment

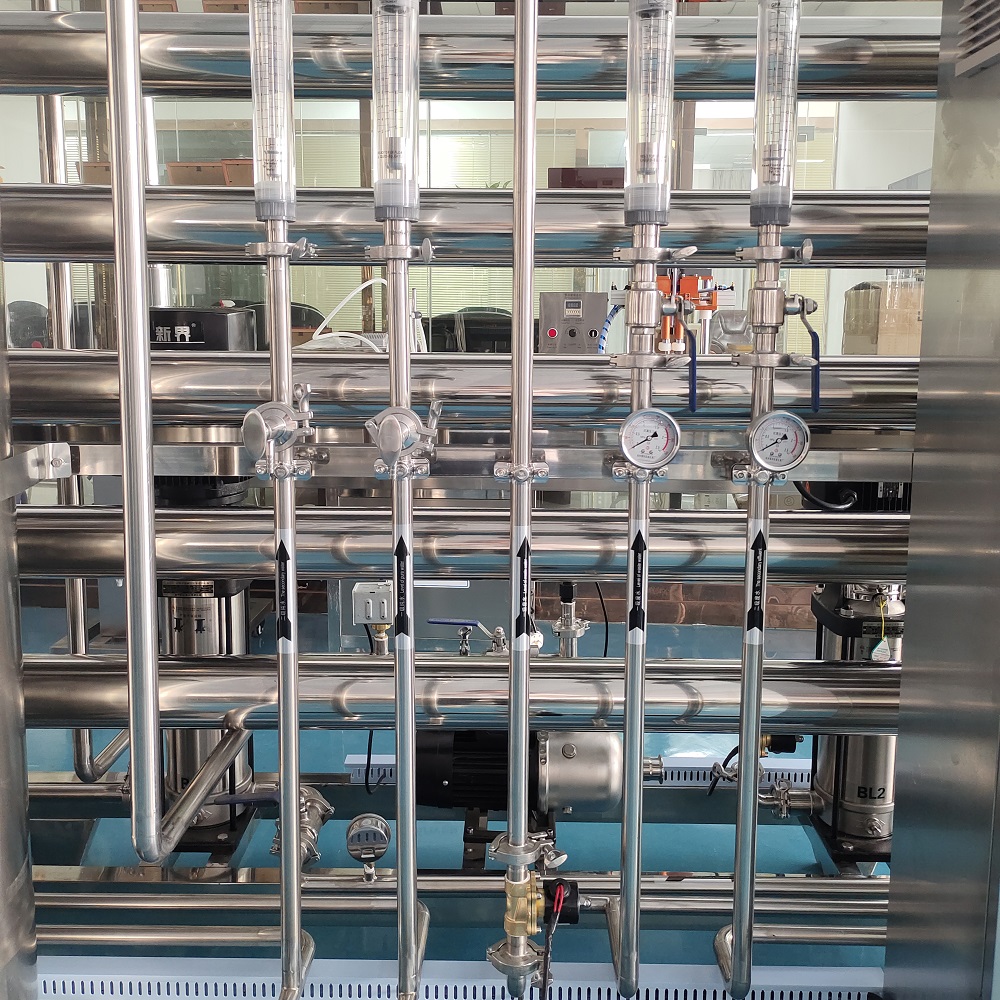

Two-Stage Stainless Steel Water Treatment Systems

Superior Water Purification

YUANYANG provides advanced two-stage stainless steel water treatment systems designed for optimal performance and longevity. Our systems utilize high-quality stainless steel construction, ensuring durability and resistance to corrosion. This ensures the highest standards of hygiene and water purity. We offer various configurations to suit your specific needs and water quality challenges.

Two-Stage Process Explained

Our two-stage process ensures thorough water purification. The first stage typically involves pre-filtration, removing larger particles and sediment. The second stage utilizes advanced filtration methods, such as reverse osmosis or ultrafiltration, to eliminate contaminants and impurities, producing clean, potable water. This two-stage approach ensures efficient and effective water treatment.

Benefits of Stainless Steel

Choosing stainless steel for your water treatment system offers significant advantages. Stainless steel is highly resistant to corrosion, ensuring the system's longevity and preventing contamination. It is also easy to clean and maintain, minimizing downtime and operational costs. Its robust construction ensures reliable performance for years to come.

YUANYANG: Your Water Treatment Partner

YUANYANG, a leading manufacturer of industrial mixing and blending equipment, also offers comprehensive water treatment solutions. With our expertise and commitment to quality, we provide reliable, high-performance systems backed by excellent customer support and free technical training. Our CE certification assures safety and compliance with European standards. Contact us to discuss your water treatment needs.

Two-Stage Stainless Steel Water Treatment for sale Display

Is this lid capping machine suitable for different shapes and sizes of bottles/jars?

Yes, the capping wheels can be adjusted higher or lower for different bottle height. The distance between wheels can be wider or closer for different cap diameter.

Can it print date on the bags, by ink or steel?

Yes, the standard machine is usually added with a ribbon coding machine to print date by ink.

Is this storage tank food grade?

Yes, the liquid tank is made of stainless steel 304 or 316L, can store food sauce, mayonnaise, cosmetic cream, lotion, pharmaceutical ointment, other liquids and paste...

Do your equipment meet GMP and other industry standards?

Yes. Our equipment fully complies with GMP, ISO, and other international industry standards and can be customized to meet specific regulatory requirements based on different markets and customers.

Do you offer customization services?

Yes, we support personalized design of equipment and adjustments based on specific customer needs.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery