Sachet Packaging Machines for Sale | YUANYANG

# High-Quality Sachet Packaging Machines

Reliable & Efficient Packaging Solutions: YUANYANG offers a range of durable and efficient sachet packaging machines designed for various industries. Our machines ensure precise filling and sealing, minimizing waste and maximizing output. We offer customized solutions to meet your specific production needs.

Turnkey Solutions for Your Business: Looking for a complete packaging line? YUANYANG provides comprehensive turnkey solutions. From mixing and blending (using our renowned vacuum homogenizers and emulsifiers) to filling, capping, labeling, and sealing, we handle it all.

Complete Production Line Equipment: Beyond sachet packaging machines, YUANYANG supplies a wide array of equipment for complete production lines. This includes storage tanks, filling machines, capping machines, labeling machines, sealing machines, coding machines, and water treatment systems. We streamline your entire process.

Exceptional Support and Training: We're committed to your success. Our team offers free technical training and on-site installation support for seamless integration of your new equipment. We're dedicated to providing comprehensive one-stop service.

Why Choose YUANYANG Sachet Packaging Machines?

* CE Certified: Ensuring safety and compliance within European Union standards.

* Proven Track Record: Years of experience supplying industrial mixing and packaging solutions globally.

* Customizable Solutions: We tailor our machines to your specific product and production requirements.

* Excellent Customer Support: We're dedicated to providing exceptional service and technical assistance.

Contact Us Today: Invest in reliable and efficient sachet packaging solutions. Contact YUANYANG today to discuss your needs and request a quote. Let us help you optimize your packaging process.

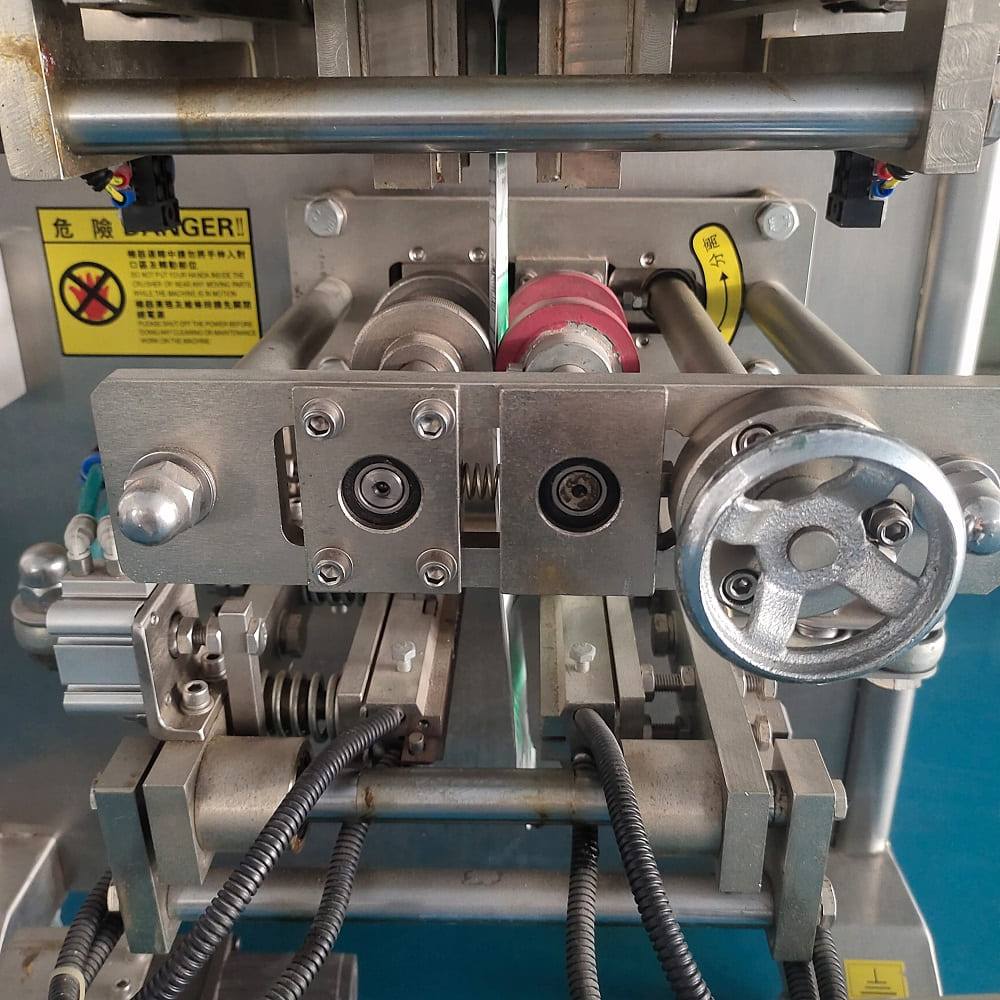

Sachet Packaging Machine for sale Display

What’s the pressure it requires?

This semi automatic filling machine is full pneumatic drive, need an air compressor. The working pressure is 0.4-0.6Mpa.

Do you have CE certificate for the homogenizing mixer, which is a must of custom clearance for goods imported to European countries?

Yes, we have applied CE for the homogenizing mixers, all the mixers are manufactured according to the standard of CE.

How extensive is your global after-sales support network?

We have a global after-sales support network that covers multiple regions to ensure that customers can receive quick responses no matter where they are located.

Is the equipment compliant with environmental standards?

Yes, all our machines meet international environmental standards, reducing emissions and supporting sustainable production.

How can you guarantee the bottom homogenizer will not leak liquids?

The bottom homogenizer adopts German mechanical sealing, As long as clients operate correctly, follow the instructions, this leakage is hardly to happen for over tens years or longer. But once the leakage accrues, just contact us to get a mechanical sealing to replace it.

Machine seal, as an indispensable sealing element in mechanical equipment, its core function is reflected in many aspects. First of all, it effectively prevents the leakage of liquid, gas or solid particles inside the machine through a tight sealing effect, as well as the intrusion of external impurities, so as to ensure that the internal environment of the machine is dry and clean.

This function is essential for extending the service life of machine equipment. Secondly, when the machine is sealed at high speed, it can prevent the condensation of water vapor caused by the heat generated by friction and play an anti-fog role. At the same time, it can effectively isolate the dust, particles and impurities generated during the work process to protect the equipment from damage.

In addition, the seal can also play an excellent waterproof role in wet environments, ensuring that the inside of the equipment is not affected by water erosion. In summary, the seal not only protects the normal operation of the mechanical equipment, but also provides a strong guarantee for the production and family life of all walks of life through its excellent sealing performance.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery