Vacuum Cosmetic Mixers | YUANYANG

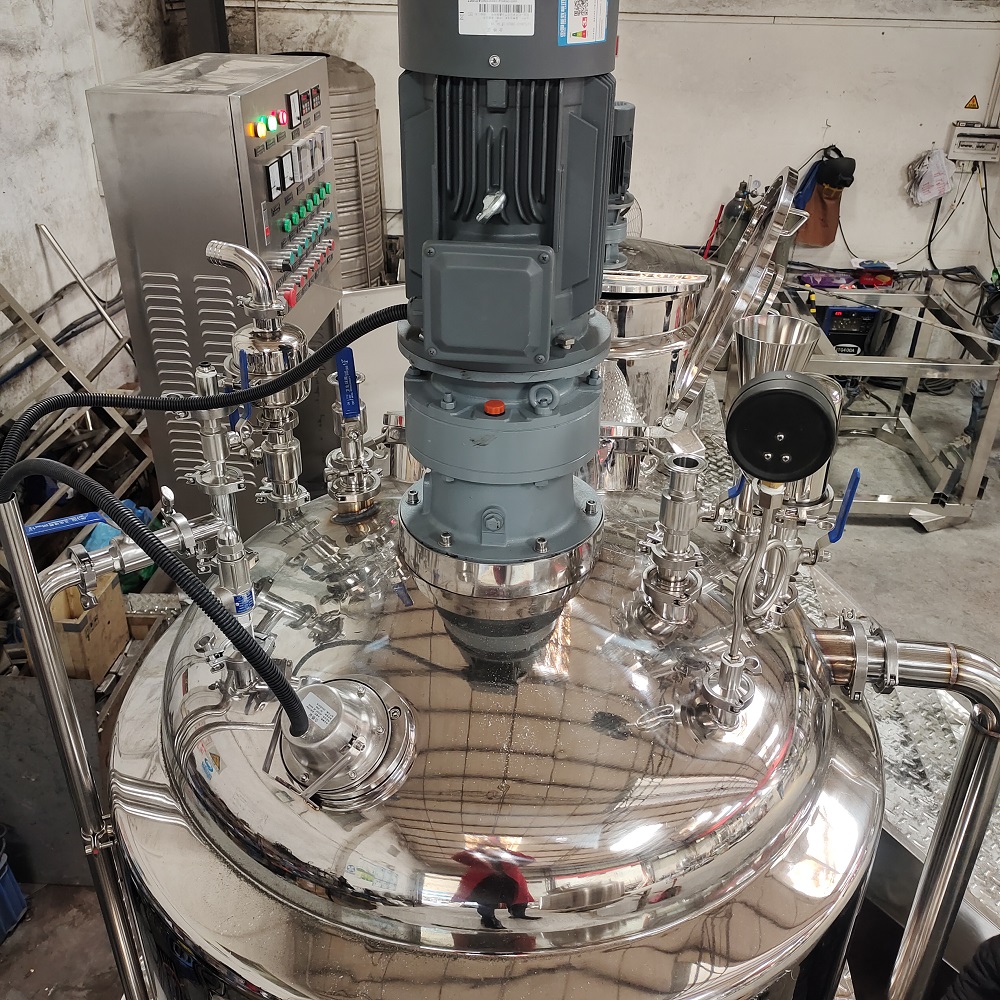

Vacuum Cosmetic Mixer with Water & Oil Tank

Superior Mixing & Blending

YUANYANG's Vacuum Cosmetic Mixers provide unparalleled performance for mixing water-based and oil-based cosmetic ingredients. Our mixers are designed for precise emulsion creation, ensuring a smooth, consistent final product. The integrated water and oil tanks streamline your production process, improving efficiency and reducing downtime.

Robust Construction & Reliability

Built to endure rigorous industrial use, our mixers boast robust construction using high-grade materials. This ensures longevity and minimal maintenance, maximizing your return on investment. Our commitment to quality is reflected in our CE certification, guaranteeing adherence to stringent European safety and health standards.

Complete Turnkey Solutions

YUANYANG offers more than just mixers. We provide complete turnkey solutions, encompassing everything from mixing equipment to packaging machinery. Benefit from our extensive experience and one-stop support, simplifying your production setup and ensuring a seamless workflow. Our free technical training ensures your team is well-equipped to operate and maintain your new equipment.

About YUANYANG: Your Trusted Partner

Established in 2008, YUANYANG is a leading China-based manufacturer of industrial mixers and blenders. We specialize in providing high-quality vacuum homogenizers, emulsifiers, and high-shear mixers, catering to diverse industries. Our dedication to customer satisfaction is evidenced by our comprehensive support services and commitment to delivering exceptional products. Contact us today to discuss your specific requirements.

Vacuum Cosmetic Mixer with Water and Oil Tank for sale Display

I don’t need homogenizer, can you reduce it?

Yes, the homogenizer is an optional function, whether clients need it depends on your own products.

What’s the production time?

Normally, the production time of the high speed dispersing mixer is 10-15 days. It depends on manufacture’s order tightness.

What’s the working principle of high shear homogenizer?

The shear mixer mainly through the high-speed relative rotation of the rotor and the stator to produce a strong shear force to achieve the refinement and homogenization of the material.

What’s the rotation speed of the top stirrer?

The standard speed of our liquid mixer machine is 60rpm. If add with speed regulator (frequency converter), the speed is variable from 0-60 rotation per minute.

Do you have in-stock or do you produce machines upon order?

Most of our products equipment are non-standard type,which should be made according to requirements,and power supply needs to be customized according to country. Therefore,we normally start to produce the products after you confirm the order.

We also have some standard machines in stock. Just contact us to confirm.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery