Top Capping Machine Manufacturers

# High Quality Capping Machine Manufacturers for Industrial Efficiency

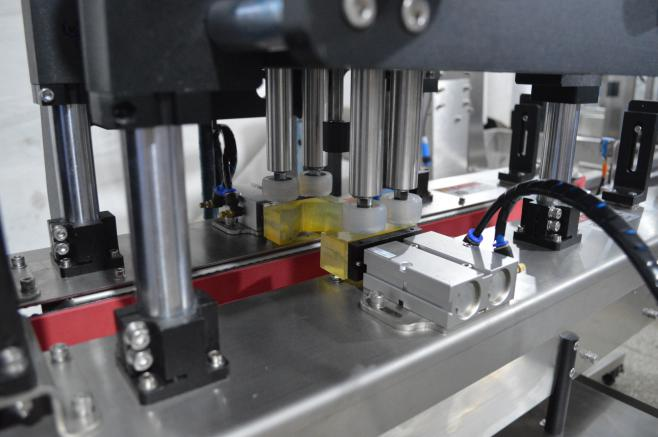

Why Choose YUANYANG Capping Machines?

YUANYANG is a trusted name among capping machine manufacturers, delivering precision-engineered solutions for diverse industries. Our machines ensure airtight sealing, durability, and high-speed performance, enhancing your production line’s efficiency. With CE certification, we guarantee compliance with EU safety standards, making us a reliable global partner.

Advanced Capping Solutions for Every Need

From automatic capping machines to semi-automatic models, YUANYANG offers versatile options tailored to your production requirements. Our portfolio includes:

- Rotary capping machines for high-volume packaging

- Spindle cappers for precise torque control

- Snap cappers for seamless bottle sealing

Each machine integrates seamlessly with filling and labeling systems, ensuring a smooth workflow.

Turnkey Production Line Support

YUANYANG provides end-to-end solutions, from capping machines to complete packaging lines. Our experts offer free technical training and one-stop installation support, minimizing downtime and maximizing productivity. Partner with us for a hassle-free, fully automated production setup.

Global Standards, Unmatched Reliability

As a leading capping machine manufacturer, we adhere to stringent quality controls. Our CE-certified machines meet international safety benchmarks, ensuring long-term performance. Whether for pharmaceuticals, cosmetics, or food packaging, YUANYANG delivers durable, high-speed capping solutions.

Your Trusted Partner in Packaging Innovation

With over 15 years of expertise, YUANYANG combines innovation with reliability. Explore our range of industrial capping machines and elevate your production efficiency. (https://www.yuanymachinery.com/) for a customized quote today!

*Optimized for SEO with targeted keywords: capping machine manufacturers, automatic capping machines, CE-certified capping solutions.*

capping machine manufacturers Display

Do you have a platform for the ribbon mixing machine?

Yes, we the platform is an optional choice, we will confirm with client before offering a quote.

Can this label dispenser stick transparent labels?

Yes, if client’s label is transparent, we will add an electric eye for the automatic labeler machine.

What capacity do you recommend for a new factory?

Vacuum homogenizer is a little expensive, and the dimension is big,compared with non-vacuum type. As a start, small capacity from 50-500L is recommended if client has limit budget. Later bigger capacity 500-5000L is considered to expand business.

For easy shipment,50-1000L is often recommended for vacuum type.

Are the machines easy to clean and maintain?

Absolutely, our equipment is designed for easy disassembly and cleaning, ideal for frequent maintenance.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery