300 Gallon Mixing Tank | High-Capacity Industrial Mixing Solutions

300 Gallon Mixing Tank – Industrial-Grade Mixing Solutions

Durable & High-Capacity Design

YUANYANG's 300-gallon mixing tanks are built for heavy-duty industrial use, offering robust construction and high-capacity performance. Ideal for chemicals, food processing, and pharmaceuticals, these tanks ensure consistent mixing with minimal downtime.

Precision Mixing Technology

Equipped with advanced agitators and homogenizers, our 300-gallon tanks deliver uniform blending for viscous and non-viscous materials. Customizable options available to meet specific production needs.

Safety & Compliance

CE-certified for EU market compliance, our mixing tanks adhere to strict safety and health standards. Trust YUANYANG for reliable, regulation-compliant industrial equipment.

Turnkey Solutions & Support

From installation to technical training, YUANYANG provides full turnkey services. Our experts ensure seamless integration with your production line for optimal efficiency.

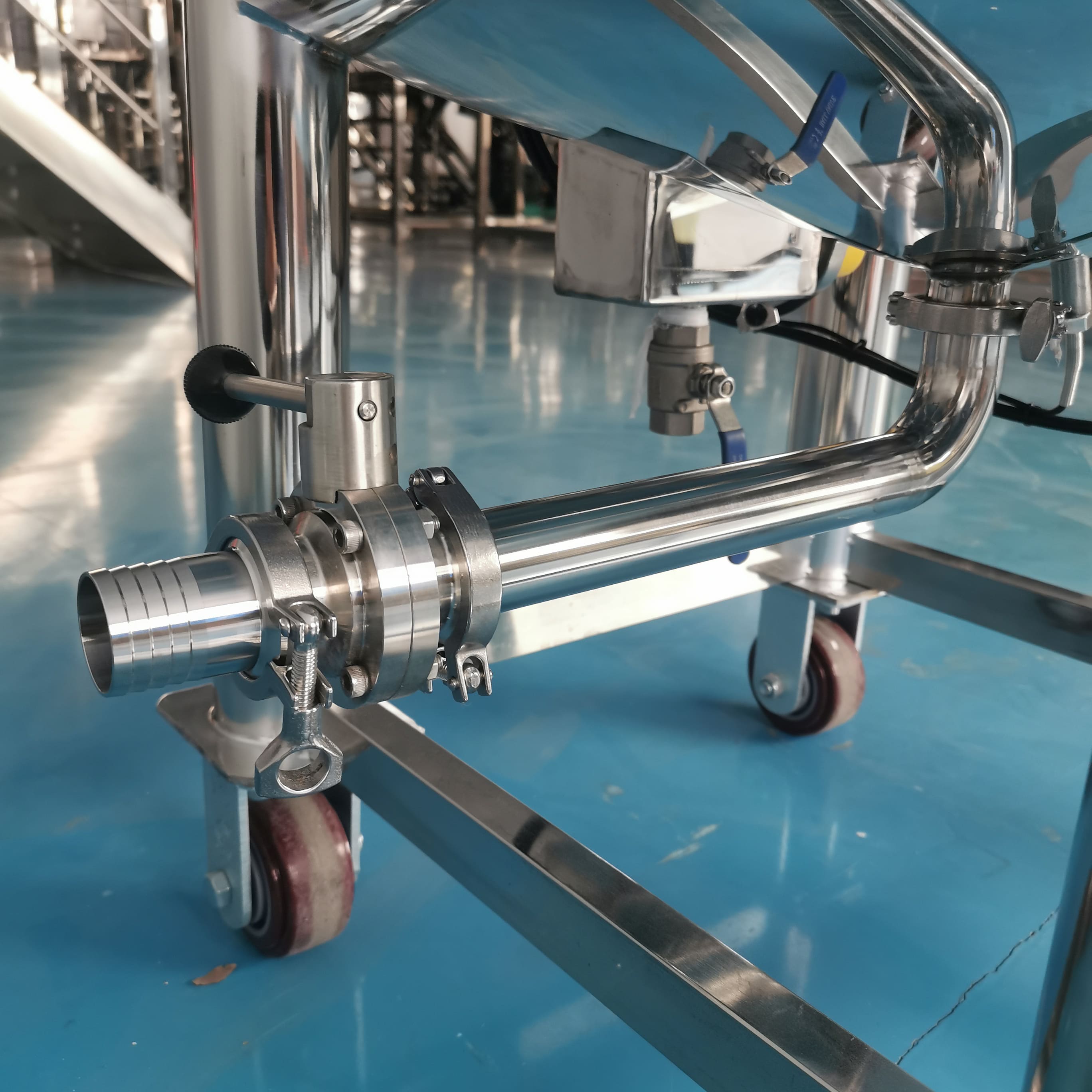

300 gallon mixing tank Display

Can the upper smaller blade move up or down?

Yes, the extra blades can be flexible fixed higher or lower based on materials depth.

Why vacuum system is necessary?

In the mixing process of cosmetic emulsifier, it is necessary to eliminate bubbles and prevent oxidation to ensure the quality of the mixture.

In a vacuum environment, there are following advantages:

⦁ Improve mixing efficiency

In a vacuum environment, the surface area of the mixture increases, and the interaction force between the substances will also increase, thus speeding up the mixing speed.

⦁ Prevent oxidation

In a vacuum environment, oxygen cannot enter the mixture, so it can effectively prevent the oxidation of the mixture.

⦁ Reduce bubbles

In a vacuum environment, the bubbles in the mixture will be drawn out, so that you can get a bubble-free mixture.

Can I use this liquid packing machine to pack if my product is like paste which is quite thick and viscous?

Yes, heating function and mixing function can be added based on materials.

Can I customize stainless steel 316 materials for the dispersing machine?

Yes, we customize materials upon requirement.

What cutting method does the granules packaging machine have?

There are in-line cutting, pattern cutting, and in-line continuous bag cutting.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery