Reverse Osmosis Water Treatment Plant Supplier

Reverse Osmosis Water Treatment Plant Solutions for Every Industry

Reliable Purification with Reverse Osmosis Technology

YUANYANG’s reverse osmosis water treatment plants provide your business with consistently pure water, removing up to 99% of contaminants. Whether you operate in food and beverage, pharmaceuticals, cosmetics, or manufacturing, our advanced RO systems ensure your processes benefit from the highest quality water, improving product safety and efficiency.

Complete Turnkey Water Treatment Services

From design and manufacturing to seamless installation and free technical training, YUANYANG delivers complete support at every step. Our reverse osmosis water treatment plant solutions are fully customizable, integrating perfectly with your production line — including mixing, filling, capping, and packaging equipment. We help you save time and reduce costs with our one-stop service commitment.

Superior Quality and Compliance

YUANYANG reverse osmosis water treatment plants are built using High Quality, CE-certified components under rigorous industry standards. Our solutions guarantee reliable operation, low maintenance, and full compliance with local and international safety regulations. Trust YUANYANG to keep your production running smoothly and safely.

Why Choose YUANYANG for Your RO Water Treatment Needs?

- Expertly engineered solutions since 2008

- Specialized in turnkey water treatment systems

- Comprehensive after-sales and technical support

- Proven installations across multiple industries

- Recognized with CE safety certifications

Enhance your manufacturing capabilities with clean, high-purity water. Contact YUANYANG today to learn more about our reverse osmosis water treatment plant solutions and request your free technical consultation!

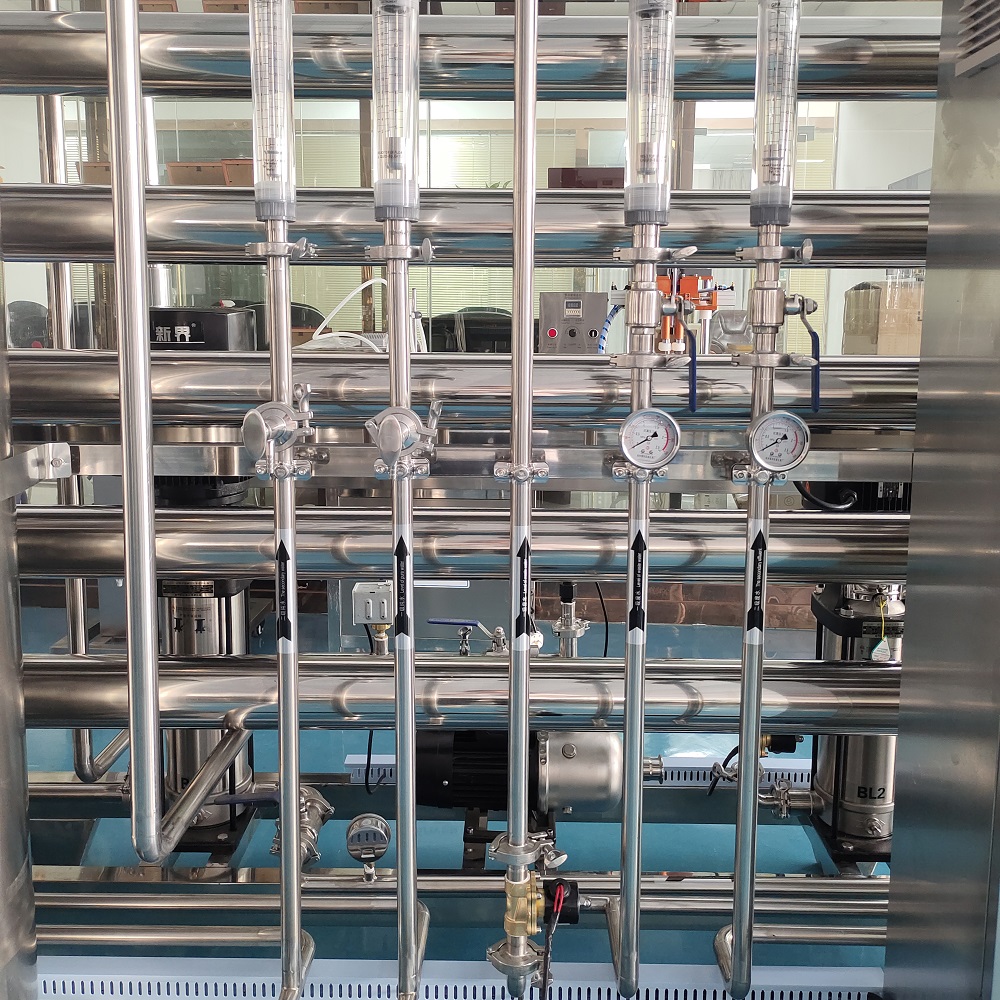

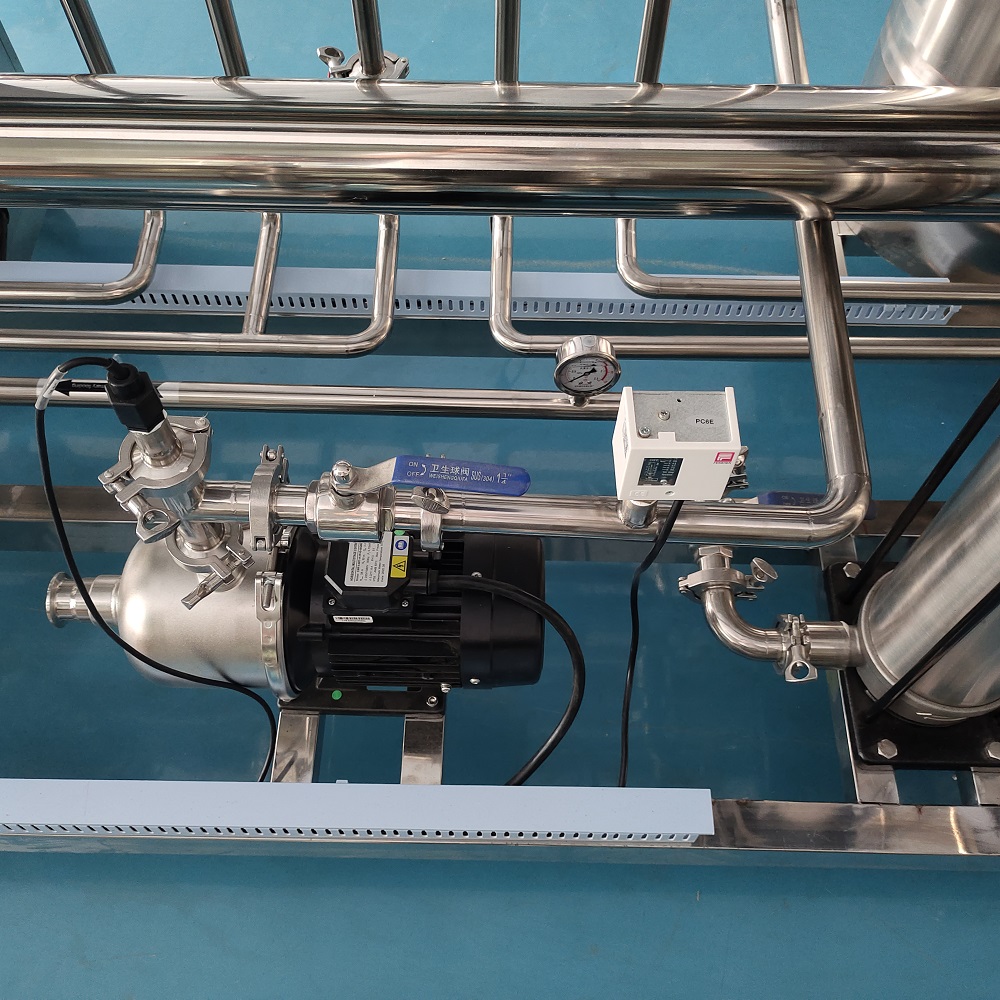

reverse osmosis water treatment plant Display

How long is the suction hose?

This hose is about 1.3 meters long. Can be longer upon requirements.

What’s the spraying system of the powder machine used for?

The spraying system is an optional function for adding liquid materials during mixing, such as perfume, essence...

What is the production capacity range of the equipment?

Our equipment has a wide range of production capacity options, which can be customized according to specific requirements.

What types labels are suitable for this jar labeling machine?

Self-adhesive label, non-adhesive film label, electronic supervision code label, bar code label, paper label, etc. However, the label paper will affect the quality of the labeling machine, so try to choose a better raw material.

Can the equipment handle various materials?

Yes, our equipment can handle a wide range of materials, including liquids, powders, pastes, and high-viscosity substances.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery