High Quality Beer Bottle Capping Machines

# High-Quality Beer Bottle Capping Machines for Efficient Production

Why Choose YUANYANG’s Beer Bottle Capping Machines?

YUANYANG delivers precision-engineered beer bottle capping machines designed for durability and efficiency. Our machines ensure airtight seals, reducing spillage and preserving beverage quality. Ideal for breweries and beverage producers, our solutions enhance productivity while maintaining industry-leading safety standards.

Key Features of Our Capping Machines

Reliable & Fast Operation

Our beer bottle capping machines feature high-speed capping with adjustable torque control, ensuring consistent performance for various bottle sizes and cap types.

CE-Certified for Safety

All YUANYANG machines comply with CE certification, guaranteeing adherence to European safety and health regulations for industrial equipment.

Durable & Low-Maintenance Design

Built with stainless steel components, our cappers resist corrosion and require minimal upkeep, reducing long-term operational costs.

Applications in the Beverage Industry

Perfect for Breweries & Bottling Lines

From craft breweries to large-scale beverage producers, our beer bottle capping machines integrate seamlessly into automated production lines, ensuring smooth, uninterrupted operations.

Customizable Solutions

YUANYANG offers tailored capping solutions, including semi-automatic and fully automatic models, to match your production volume and workflow needs.

Expert Support & Turnkey Services

Free Technical Training

We provide hands-on training to ensure your team operates our machines efficiently, maximizing uptime and performance.

Complete Production Line Integration

Beyond capping, YUANYANG supplies mixing, filling, labeling, and packaging equipment, offering a one-stop solution for beverage production lines.

Trust YUANYANG for High Quality Beverage Machinery

With over 15 years of expertise, YUANYANG is a trusted name in industrial mixing and packaging solutions. Our beer bottle capping machines combine innovation, reliability, and compliance—ensuring your business stays ahead.

Contact us today for a customized quote and elevate your bottling efficiency!

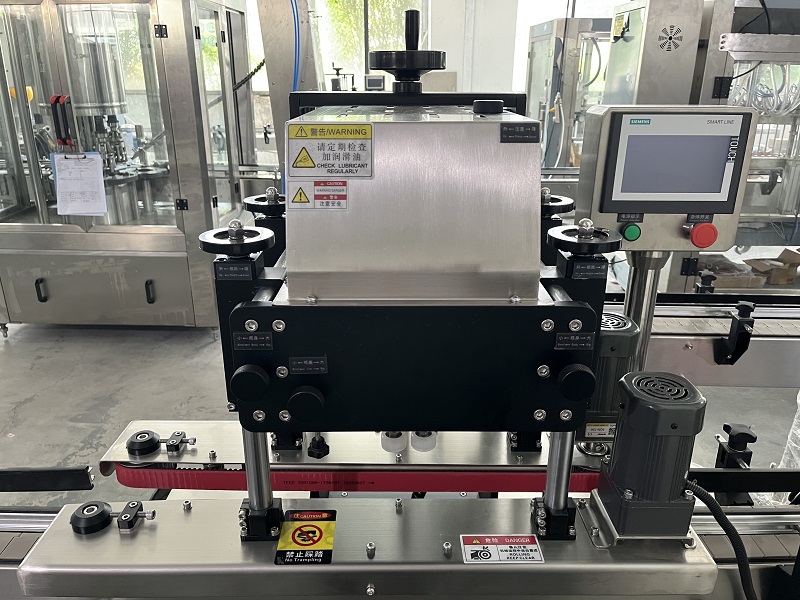

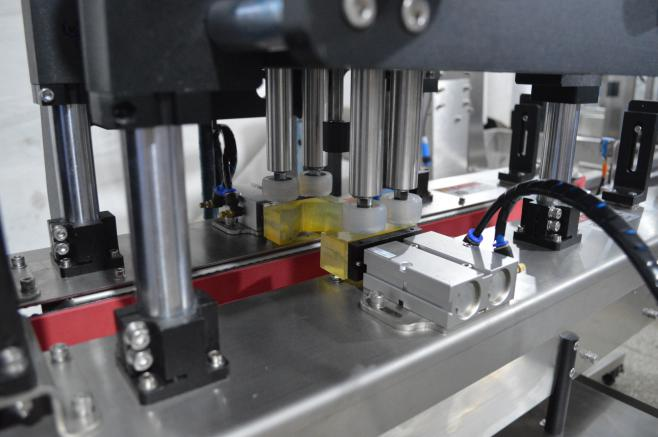

beer bottle capping machine Display

What capacity do you provide for the mixing tank with agitator?

The steel tank with agitator has different capacity from 50L to 5000L.

Is the length of bag-forming adjustable for this automatic packing machine?

Yes, the bag-forming length can be adjusted on the control panel within certain range of the model.

Is the powder screening machine used for detergent powder?

Yes, this can be used for detergent powder. It is a detergent powder screening machine.

How to clean the inside tank?

There will be installed with rotary ball and valves on the lid, client uses high pressure water to clean or a high pressure gun to wash. Load tap water into tank, add some cleaning liquids, operate heating function and mixing function for better cleaning.

Will do test for the machine I order before production?

Yes, every machine will be test and are assured without problems before packing. Therefore, clients will never worry about the quality. Only when clients are satisfied with the finished machine can we pack and ship.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery