YUANYANG Boba Tea Sealing Machines: Precision & Efficiency for Your Beverage Business

YUANYANG Boba Tea Sealing Machines: Precision, Efficiency, and Reliability for Your Beverage Production

Elevate your boba tea and beverage operations with YUANYANG's cutting-edge sealing machines. In the fast-paced world of cafes, restaurants, and beverage production, a perfect seal is paramount for maintaining product freshness, preventing spills, and enhancing customer satisfaction. YUANYANG, a trusted name in industrial machinery since 2008, brings its expertise in complete production line solutions to deliver high-performance boba tea sealing machines designed for precision, hygiene, and seamless integration into your workflow.

Why Choose YUANYANG Boba Tea Sealing Machines?

YUANYANG is renowned not just for our industrial mixers and agitators, but also for our comprehensive range of production line equipment, including state-of-the-art sealing machines. Our boba tea sealing machines are engineered to meet the demanding needs of modern beverage businesses. Whether you require a semi-automatic model for smaller operations or a fully automatic system for high-volume production, YUANYANG offers robust, user-friendly solutions that ensure consistent, air-tight seals every time. Experience reduced waste, increased efficiency, and a professional finish that sets your products apart.

Precision Sealing for Perfect Boba Tea

Our boba tea cup sealing machines are built with advanced technology to guarantee optimal performance. Key features include precise temperature control for various film types, rapid sealing cycles, and durable construction for long-term reliability. From milk tea and fruit tea to smoothies and juices, our machines provide a secure, tamper-evident seal that preserves flavor, hygiene, and extends shelf life. Ease of operation and quick film changes minimize downtime, allowing your team to focus on serving delicious beverages efficiently.

Integrating into Your Complete Production Line

At YUANYANG, our commitment extends beyond individual machines. Since 2008, we have specialized in providing complete production line equipment, including mixing equipment, storage tanks, filling machines, capping machines, labeling machines, and sealing machines. This holistic approach means our boba tea sealing machines are designed for effortless integration with other YUANYANG equipment, ensuring a smooth, cohesive production process. We offer free technical training and one-stop installation support, providing full turnkey services to get your entire line up and running efficiently.

YUANYANG: Your Trusted Partner for Beverage Production

As a leading manufacturer, YUANYANG is dedicated to quality and customer success. Our products, including our boba tea sealing machines, proudly carry multiple CE certifications, affirming our adherence to high safety and health standards required for the European market and beyond. Our vision is to become the best industrial mixer and agitator manufacturer in the world, and this commitment to excellence permeates every product we build. Partner with YUANYANG for reliable equipment, unparalleled support, and a pathway to optimized beverage production. Visit https://www.yuanymachinery.com/ to explore our solutions.

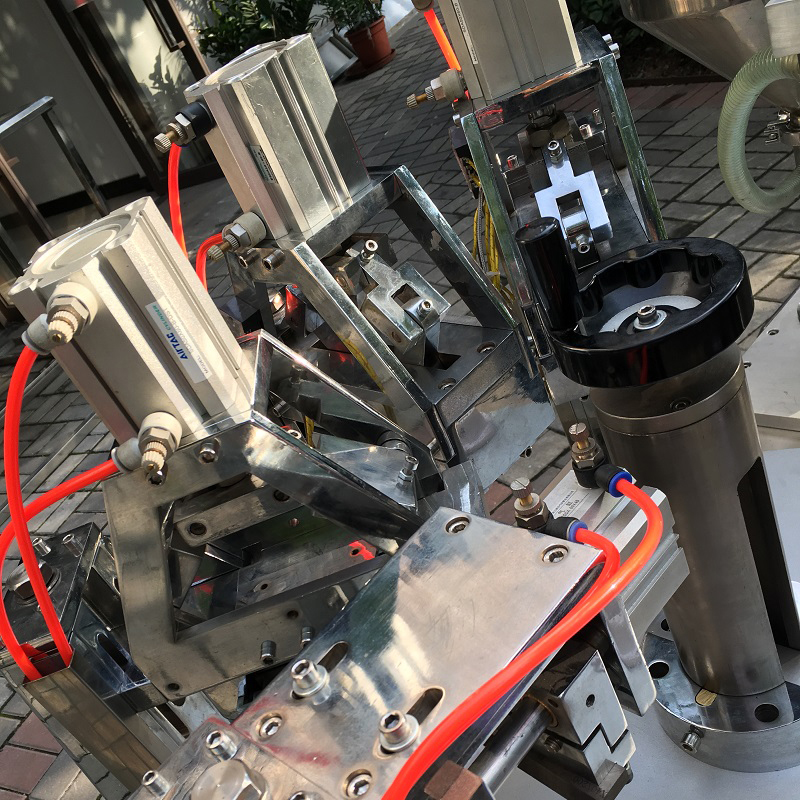

boba tea sealing machine Display

Do you provide operational training?

Yes, we provide detailed operational manuals and comprehensive training to ensure safe and efficient operation of the equipment.

Can the upper smaller blade move up or down?

Yes, the extra blades can be flexible fixed higher or lower based on materials depth.

Can your equipment integrate with existing production lines?

Yes. Our equipment can seamlessly integrate with your existing production lines, ensuring smooth operation without disruptions.

Can this capping machine for bottles be connected with filling machine,or labeling machine?

Yes, if client already has an old automatic labeling machine, just tell the conveyor height, we will customize our capping machine height.

Do you have a platform for the ribbon mixing machine?

Yes, we the platform is an optional choice, we will confirm with client before offering a quote.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery