Emulsifier Mixer Product Category - YUANYANG Industrial Mixers

Emulsifier Mixer Solutions by YUANYANG

YUANYANG offers a complete range of emulsifier mixer equipment designed for reliable, repeatable and scalable mixing. Our product family includes vacuum homogenizers, vacuum emulsifying mixers and high shear mixers engineered to produce stable emulsions, creams, lotions and chemical dispersions. With over a decade of industry experience since 2008, YUANYANG combines manufacturing expertise and modern design to meet demanding production standards.

Key Features and Design Benefits

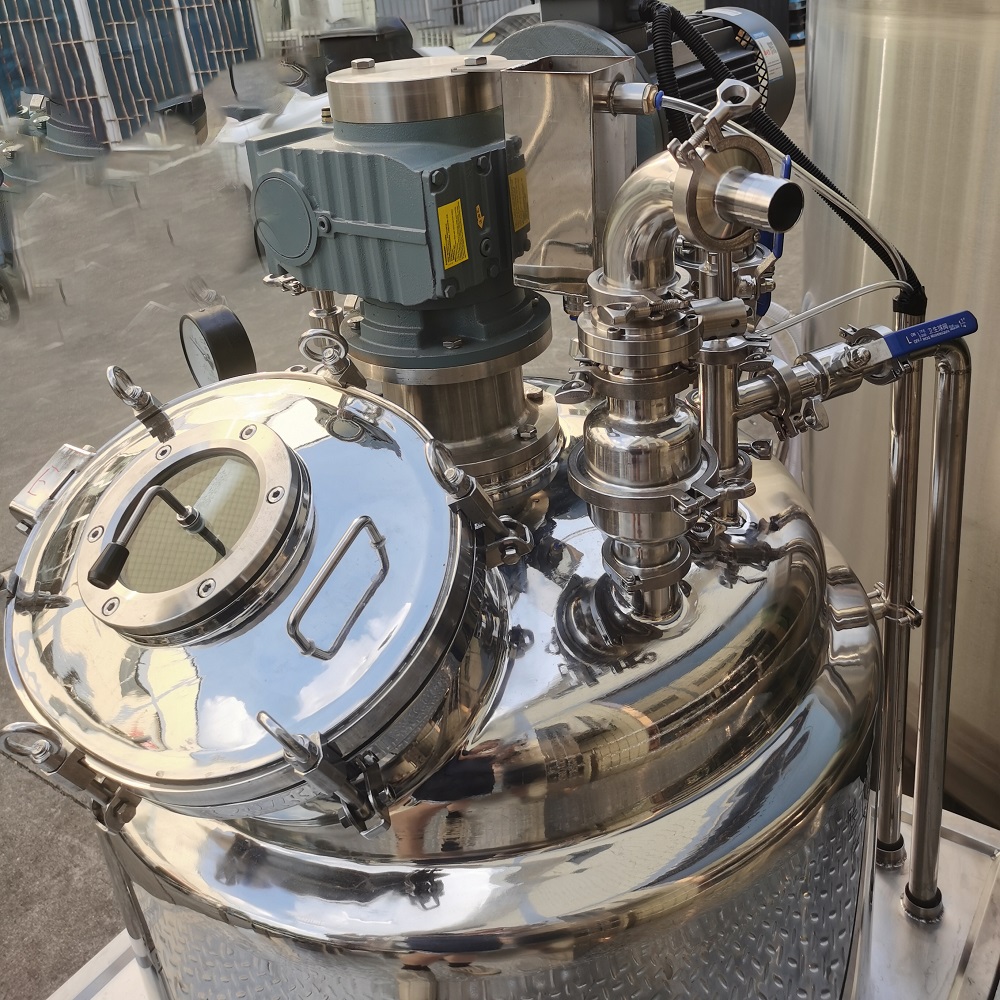

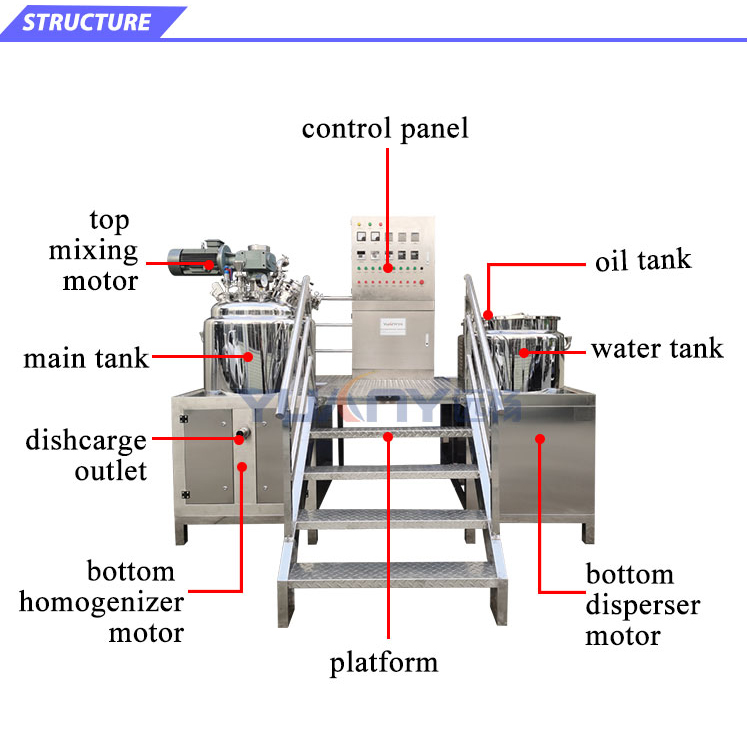

YUANYANG emulsifier mixers feature precision-controlled agitation, adjustable shear rates and integrated vacuum systems to remove entrapped air and improve emulsion stability. Constructed from sanitary stainless steel and available with various impeller and rotor-stator configurations, our mixers optimize heat transfer, viscosity control and particle size reduction for consistent product quality.

Applications Across Industries

Our emulsifier mixer solutions serve cosmetics, pharmaceuticals, food, chemical formulations and specialty manufacturing. Typical uses include creams, ointments, sauces, paints, adhesives and polymer dispersions. The range of vacuum emulsifying mixers and high shear mixers makes scaling from R&D to full production seamless and efficient.

Turnkey Services and Technical Support

YUANYANG provides end-to-end production line equipment including mixing systems, storage tanks, filling, capping, labeling, sealing, inkjet printing and water treatment. We offer free technical training, on-site installation support and one-stop turnkey services to reduce ramp-up time and ensure operational safety and compliance.

Safety, Certification and Trust

YUANYANG has obtained multiple CE certifications, demonstrating conformity with EU safety and health requirements. Our commitment to Google E-E-A-T-level expertise is reflected in experienced engineering teams, documented performance data and transparent service policies. We aim to be the world’s best industrial mixer and agitator manufacturer.

Why Choose YUANYANG Emulsifier Mixers

Choose YUANYANG for robust emulsifier mixer technology, proven reliability and comprehensive after-sales support. Visit https://www.yuanymachinery.com/ to explore models, request specifications or contact our sales engineers for tailored solutions and quotes.

emulsifier mixer Display

Can you add circulation system for the shampoo production machine?

Yes, the mixing machines can be added with a pump with circulation system. We customize upon requirements.

Can the plastic powder packing machine print barcode also?

No, the standard type of coding machine on this packing machine for powders can only print date. To print barcode, customize service will recommend client another separated jet printer.

What types bottles are suitable for this label dispenser?

It is suitable for single side and double side labeling of flat bottles, round bottles and square bottles, such as shampoo, laundry detergent flat bottles, lubricating oil flat bottles, hand sanitizer round bottles and other double side labeling, both sides of the same labeling, double labeling improves production efficiency, and is widely used in daily chemical, cosmetics, petrochemical, pharmaceutical and other industries.

Can the powder feeder work automatically with packing machine?

The feeder can automatically add materials and stop at the right time if the packing machine hopper is installed with material sensor.

The products is too viscous, is the chemical storage tank easy for discharge?

We recommend pressurized storage tank type for easy discharge.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery