YUANYANG Vacuum Emulsifying Mixer Price | Industrial Mixers Expert

Affordable Vacuum Emulsifying Mixer Price with Unmatched Quality

YUANYANG is a leading manufacturer in China specializing in industrial mixers, including vacuum emulsifying mixers that balance advanced technology with competitive vacuum emulsifying mixer price. Since 2008, our expertise in blending mixing equipment with turnkey production line solutions ensures every customer receives cost-effective equipment without compromising quality or performance.

Innovative Vacuum Emulsifying Mixers Designed for Efficiency

Our vacuum emulsifying mixers integrate high shear homogenization and vacuum technology to deliver uniform and stable emulsions, suitable for cosmetics, pharmaceuticals, food, and chemical industries. With YUANYANG, affordable vacuum emulsifying mixer price means access to reliable, efficient machinery designed for long-term industrial use.

Comprehensive Turnkey Services and CE-Certified Equipment

YUANYANG offers more than just mixing equipment. We provide free technical training, one-stop installation support, and a complete suite of production line machinery such as storage tanks, filling and capping machines, labeling and sealing systems, alongside water treatment equipment. All our mixers carry multiple CE certifications, ensuring compliance with EU safety and health standards.

Why Choose YUANYANG for Your Industrial Mixing Solutions?

Our vision to become the world’s best industrial mixer manufacturer is reflected in every product we deliver. Competitive vacuum emulsifying mixer price combined with excellent after-sales support and technical expertise makes YUANYANG your trusted partner for all industrial mixing needs. Visit www.yuanymachinery.com to explore our full product range and request a quote today.

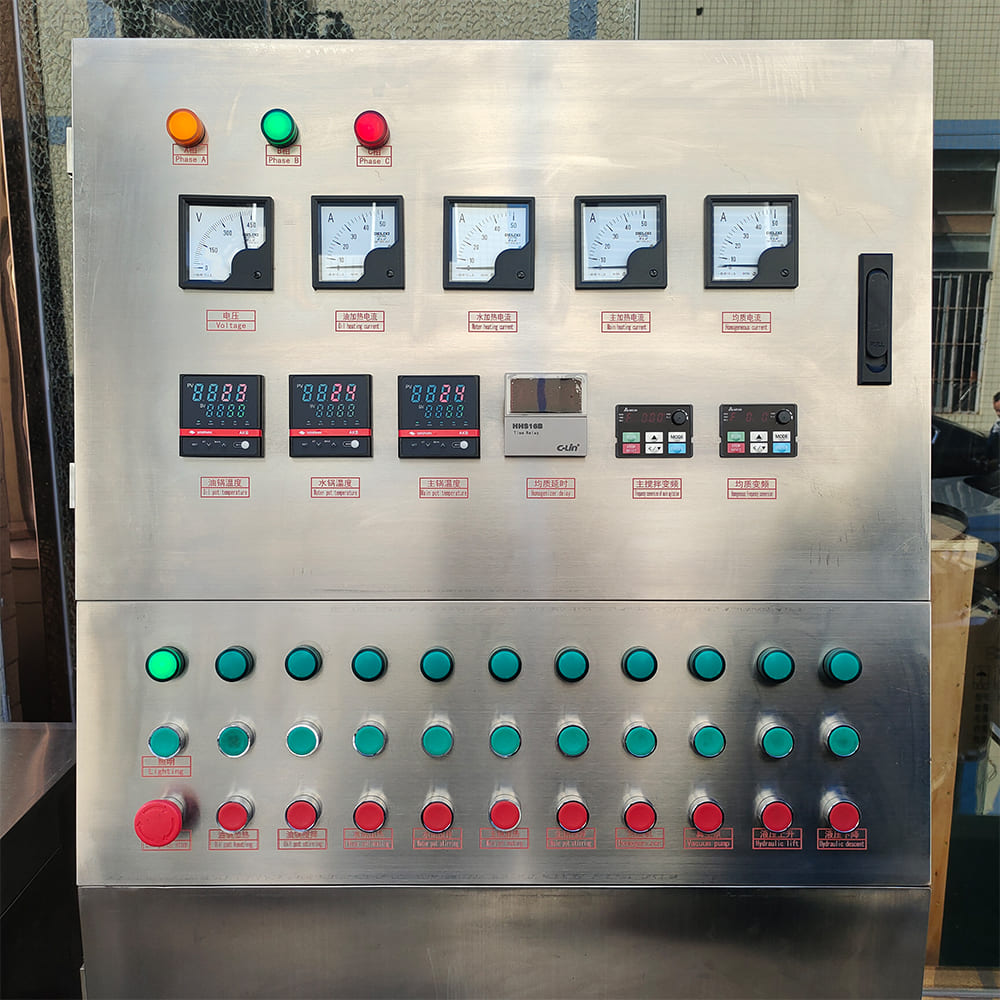

vacuum emulsifying mixer price Display

Is this storage tank food grade?

Yes, the liquid tank is made of stainless steel 304 or 316L, can store food sauce, mayonnaise, cosmetic cream, lotion, pharmaceutical ointment, other liquids and paste...

What’s the maximum temperature it can get?

Steam heating: 100~180℃; electric heating: use water 100℃, use thermal oil 260℃.

What’s the thickness of the stainless steel tank for liquids?

The standard thickness for finished products is 3mm, the water tank thickness is 2mm. But the bigger capacity, the layer will be thicker.

Can you customized contact materials stainless steel 316L for the detergent powder making machine ?

Yes, we provide customization service upon requirements. The contact parts can be SUS304 or SUS316L. But the cost will be more.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery