Food Vacuum Emulsifying Mixer - Premium Industrial Mixing Solutions by YUANYANG

Food Vacuum Emulsifying Mixer: Efficient Industrial Mixing by YUANYANG

Advanced Technology for Optimal Food Processing

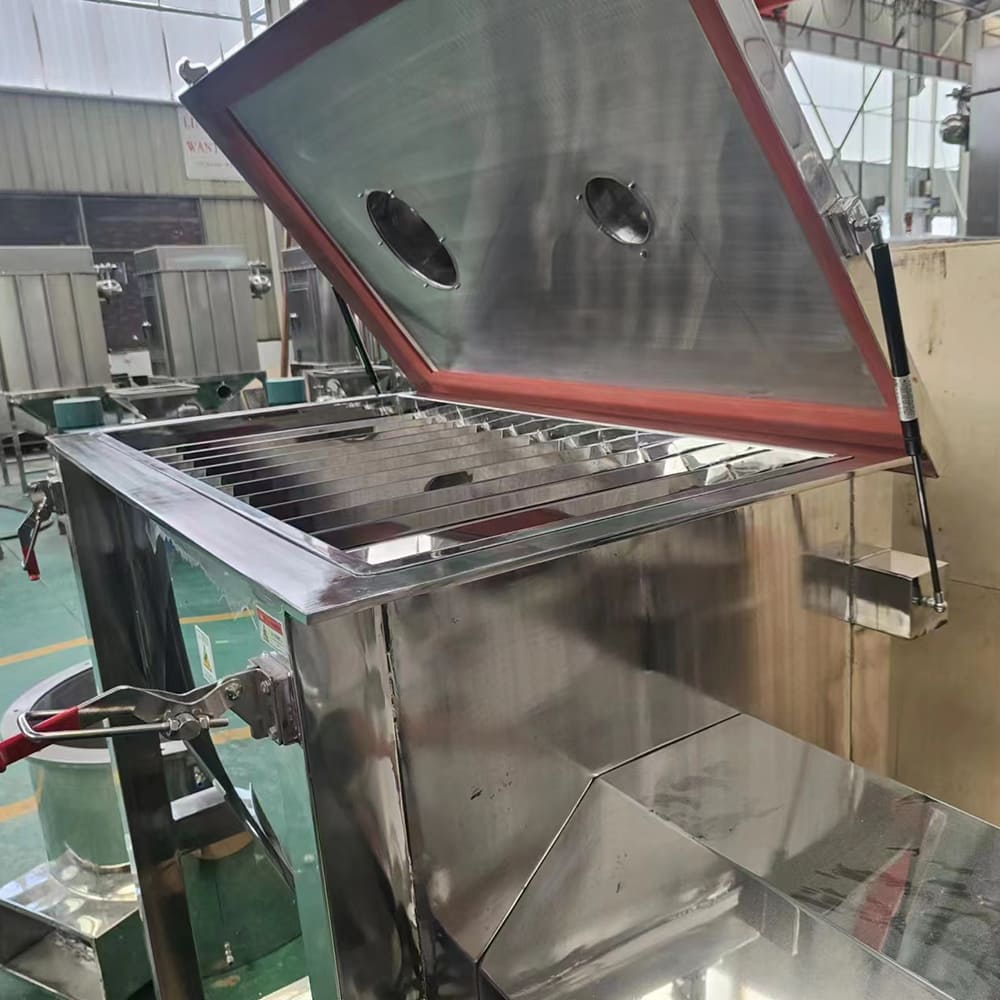

YUANYANG’s food vacuum emulsifying mixer integrates cutting-edge vacuum homogenizing and emulsifying technology, ensuring consistent, high-quality mixing results. Ideal for the food industry, our mixers handle liquids, creams, pastes, and emulsions with superior uniformity while maintaining hygiene and preserving product integrity.

Key Features and Industrial Benefits

Equipped with a vacuum system, high shear mixer blades, and precision controls, the food vacuum emulsifying mixer reduces air bubbles and prevents oxidation, improving product texture and shelf life. Our mixer supports a wide range of food applications including sauce, mayonnaise, dressings, dairy products, and more. With CE certification and robust build quality, it meets stringent safety and health standards, ensuring reliable operation worldwide.

Comprehensive Turnkey Solutions from YUANYANG

Since 2008, YUANYANG has specialized in providing complete production line equipment and services. Beyond the food vacuum emulsifying mixer, we offer integrated solutions including storage tanks, filling machines, and labeling equipment. Our expert team delivers free technical training and installation support, enabling your team to operate smoothly and efficiently.

Why Choose YUANYANG for Your Industrial Mixing Needs?

As a leader in industrial mixers and agitators manufacturing in China, YUANYANG combines innovation with reliability. Our commitment to quality, CE certification compliance, and customer service excellence makes us your trusted partner. Choose YUANYANG to elevate your food production process with advanced vacuum emulsifying mixer technology.

food vacuum emulsifying mixer Display

Is there a powder feeder for the powder dosing machine?

Yes, we have corresponding auger feeder for powder conveying. There is inlet port on the hopper to be connected with powder feeding machine.

The screw powder feeder is an option for client, which can achieve automatic adding materials and stop working with materials sensor installed in hopper.

Do you have different diameter for the vibrating sieve machine?

Yes, we will recommend the suitable type according to capacity.

How to achieve vacuum environment?

The vacuum pump is a device used to generate vacuum, which can draw out the gas in the container to form a vacuum environment. Close wall pipe valves,only open the vacuum pipe pass-by valve,also open the water inlet of vacuum pump,then operate vacuum button. After the the tank get the standard pressure such -0.05Mpa (check the pressure gauge), stop the vacuum operation,close the pass-by valve.

Can you make a bigger material hopper for the screw feeder machine?

Yes, the hopper capacity can be customized bigger according to needs.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery