Top Liquid Mixers

# High Quality Liquid Mixers for Industrial Applications

Why Choose YUANYANG Liquid Mixers?

YUANYANG delivers cutting-edge liquid mixers designed for precision, durability, and efficiency. As a leading manufacturer since 2008, our CE-certified mixers—including vacuum homogenizers, high-shear mixers, and emulsifying systems—ensure seamless blending for industries like cosmetics, pharmaceuticals, and food processing. Backed by free technical training and turnkey installation, we provide end-to-end solutions for your production needs.

Types of Liquid Mixers We Offer

Vacuum Homogenizers

Ideal for creamy textures, our vacuum homogenizers eliminate air bubbles, ensuring smooth, consistent results in cosmetics and pharmaceuticals.

High-Shear Mixers

Engineered for rapid emulsification, these mixers reduce particle size, enhancing product stability in chemicals and food production.

Vacuum Emulsifying Mixers

Perfect for high-viscosity blends, these systems integrate heating, mixing, and vacuum functions for superior homogeneity.

Key Benefits of YUANYANG Mixers

Unmatched Efficiency

Our industrial-grade liquid mixers optimize production speed while maintaining energy efficiency, reducing operational costs.

CE-Certified Safety

Compliant with EU standards, YUANYANG mixers prioritize operator safety and long-term reliability.

Customizable Solutions

From small batches to full production lines, we tailor equipment to your capacity and industry requirements.

Partner with a Trusted Manufacturer

YUANYANG’s one-stop service covers design, installation, and after-sales support. Explore our range at (https://www.yuanymachinery.com/) and elevate your mixing process today!

*Optimized for SEO with targeted keywords: liquid mixer, industrial mixers, vacuum homogenizer, high-shear mixer.*

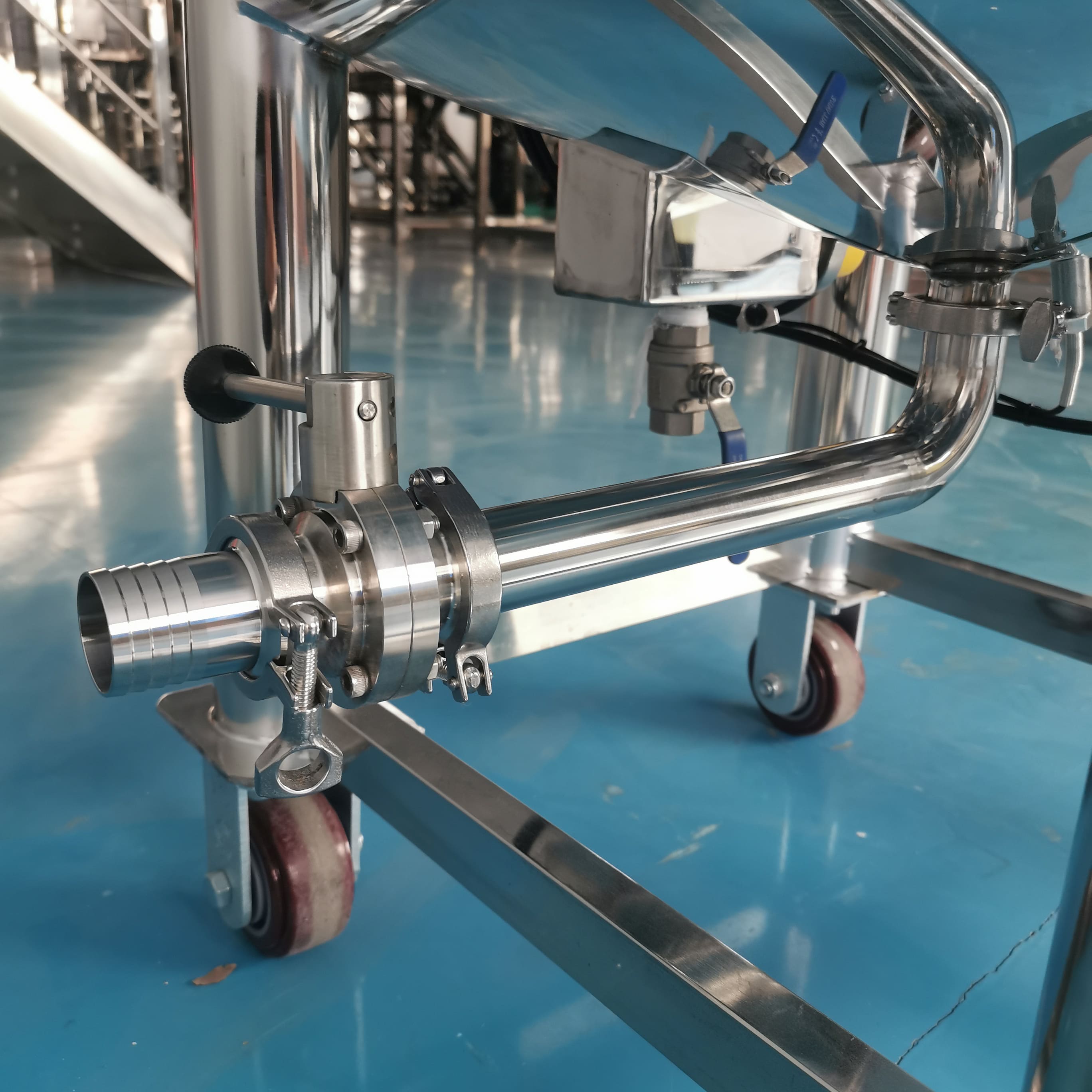

liquid mixer Display

Is there a bottle gripper to keep thin bottles stable?

Yes, the auto servo capping machine is equipped with pneumatic clamping device for bottle stability.

Can this capping machine for bottles be connected with filling machine,or labeling machine?

Yes, if client already has an old automatic labeling machine, just tell the conveyor height, we will customize our capping machine height.

What’s the pressure it requires?

This semi automatic filling machine is full pneumatic drive, need an air compressor. The working pressure is 0.4-0.6Mpa.

What’s the spraying system of the powder machine used for?

The spraying system is an optional function for adding liquid materials during mixing, such as perfume, essence...

What else can the bottle coding machine print others except date?

Yes, the date coding machine can print batch number, logo, product name, production date, expiration date, number, bar code, QR code, pictures, etc.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery