Industrial Labeling Machines

Industrial Labeling Machines for Reliable Product Identification

Streamline Your Production with YUANYANG Labeling Machines

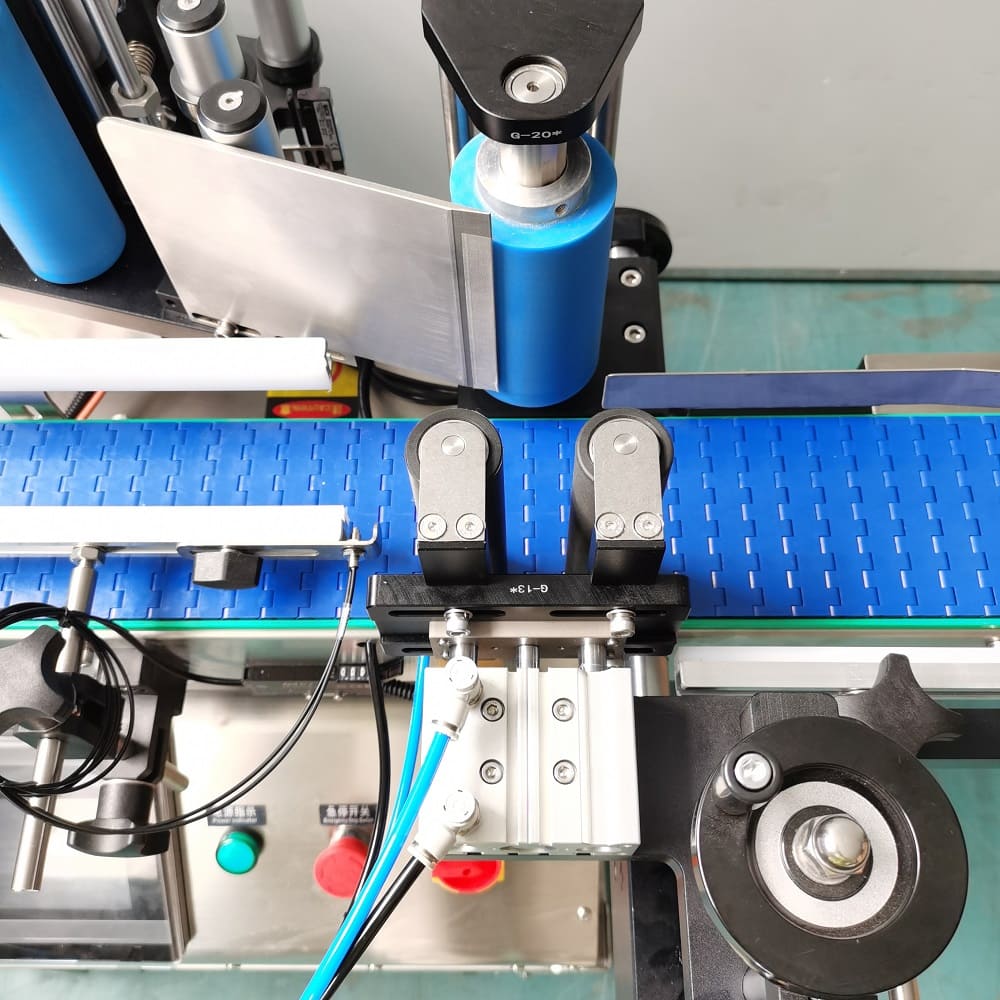

YUANYANG's advanced labeling machines are designed to integrate seamlessly with your complete production line. Our equipment ensures precise and consistent label application on bottles, jars, containers, and more, helping you maintain professional standards and enhanced brand visibility. Perfect for various industries, our labeling machines increase productivity and minimize costly manual errors.

Advanced Technology for Enhanced Efficiency

Our industrial labeling machines feature user-friendly control systems, rapid changeover capabilities, and compatibility with different container shapes and sizes. Whether you require wrap-around, front-and-back, or top labeling, YUANYANG offers configurable solutions powered by years of technical expertise and innovation. CE certification guarantees compliance with European safety and health standards.

Custom Solutions to Meet Production Needs

Every business has unique needs. YUANYANG delivers tailored labeling machine solutions, ideal for cosmetics, pharmaceuticals, food, and more. Our experienced team offers free technical training and one-stop turnkey installation support, ensuring your operation runs smoothly from start to finish.

Why Choose YUANYANG Labeling Machines?

Choosing YUANYANG means partnering with one of China's best industrial mixer and production line equipment specialists. Since 2008, we have supplied reliable, high-performance machines, including labeling machines, to clients worldwide. With strong after-sales support and CE-certified products, you can trust us for efficient, long-lasting solutions.

Contact Us for Expert Guidance

Ready to modernize your production line? Contact YUANYANG today for expert advice on industrial labeling machine selection, installation, and maintenance. Let us power your success with advanced automation and unbeatable service.

Keywords used: labeling machine, industrial labeling machines, CE certification, production line, turnkey support.

labeling machine Display

Can packing machinery be used for different film size?

The sachet packing machine for powders is suitable for different film width, but need to customize the bag-former for specific film width, then clients just need to replace the corresponding model for another film width.

What’s the material of the liquid tank?

The tank is made of stainless steel 304 or 316L. We customize upon requirements. Or we recommend according to clients’ products.

Can you add heating function for the storage tank for liquids?

Yes, the tank can be customized with jacket for heating upon requirements.

Can you explain the heating principle? How does it achieve heating purpose?

The jacket tank transmits heat to the liquid through the principle of heat conduction, and the heat medium in circulation between the inner wall and the jacket is responsible for conducting heat and transferring the temperature of the jacket heat medium to the liquid product.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery