YUANYANG Vacuum Emulsifier Mixers — Industrial Emulsifiers

YUANYANG Vacuum Emulsifier Mixers

Overview

YUANYANG is a leading Chinese manufacturer of industrial mixers and agitators, specializing in vacuum emulsifier equipment. Our product range includes vacuum homogenizers, vacuum emulsifying mixers, high shear mixers, and complementary vacuum mixers designed to deliver stable emulsions, fine dispersions and repeatable product quality across cosmetics, pharmaceuticals, food and chemical production.

Advanced Features & Technology

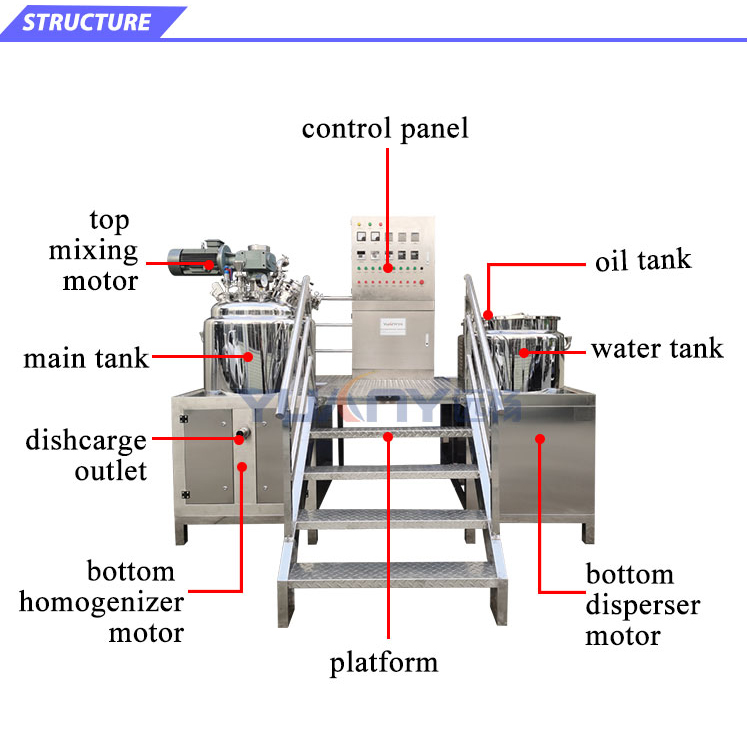

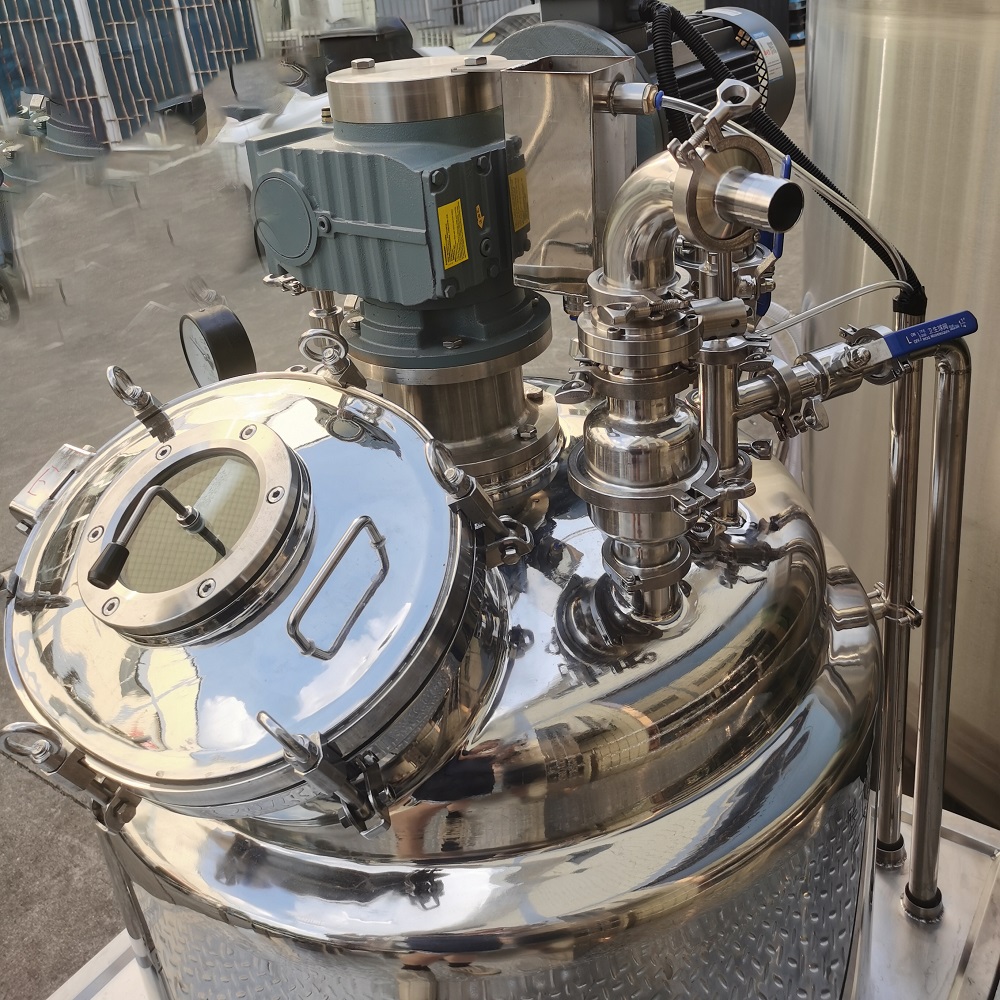

Each vacuum emulsifier is engineered for efficiency and hygiene: jacketed mixing tanks, precision homogenizing heads, variable-speed high-shear systems and robust vacuum systems to remove air and bubbles. Materials and surface finishes meet sanitary standards and options include PLC control, CIP systems and custom-scale configurations to match batch sizes and production rates.

Applications and Performance

YUANYANG vacuum emulsifier mixers excel in creams, lotions, ointments, sauces and emulsions where particle size control, homogeneity and shelf stability are critical. The combination of vacuum de-aeration and high-shear homogenization reduces foaming, improves texture and enhances appearance—delivering consistent, scalable results from R&D to full production.

Turnkey Solutions, Training & Certification

Since 2008 YUANYANG has provided complete production line equipment, including mixing systems, storage tanks, filling and capping machines, labeling, sealing, inkjet printers and water treatment. We offer free technical training, one-stop installation support and full turnkey services. Multiple CE certifications ensure compliance with EU safety and health requirements for market access.

Why Choose YUANYANG

With a commitment to innovation and a vision to become the world’s best industrial mixer manufacturer, YUANYANG pairs proven vacuum emulsifier technology with responsive service. Our team supports product development, scale-up and after-sales maintenance—so manufacturers gain dependable equipment, faster production ramp-up and lower operational risk.

vacuum emulsifier Display

Can I set the sealing length on the control panel of automatic packing machine?

Yes, each machine has a sealing length range regarding bag size, it is flexible to change the length on the micro control system within available range.

What are the core values of your company?

We holding the principle of surviving by quality and developing by reputation,providing solution-oriented service.

Can it fill the paste like dough?

No, the dough is too viscous and can’t flow down. The materials must be easy to flow down for this vertical filling machine. And for too viscous paste, pressure filling machine or heating mixing filling machine will be recommended based on materials.

What’s the motor brand of this semi automatic powder packing machine?

The filling motor is with Servo motor, which has high filling precision.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery