Elevate Your Fragrance Production with YUANYANG Perfume Filler Machines

Elevate Your Fragrance Production with YUANYANG Perfume Filler Machines

The delicate art of perfumery demands not just exquisite formulation, but also flawless presentation. At YUANYANG, one of China's leading manufacturers of industrial mixers and agitators since 2008, we understand this precision. Our expertise extends beyond vacuum homogenizers and high shear mixers to encompass the entire production journey, including highly specialized Perfume Filler machines designed to bottle your fragrances with unparalleled accuracy and care.

Precision and Purity: The YUANYANG Advantage in Perfume Filling

Crafting a superior perfume requires meticulous attention to every detail, and filling is no exception. YUANYANG's perfume filler machines are engineered to handle the unique characteristics of fragrance liquids – often volatile, delicate, and high-value. We ensure precise volumetric or gravimetric filling, minimizing waste and guaranteeing consistent product levels in every bottle. Our fillers are constructed from high-grade stainless steel, ensuring hygienic operations and preventing contamination, which is paramount for maintaining the integrity and purity of your exquisite scents. Leveraging our deep understanding of liquid handling from our core mixing equipment, our filling solutions are designed for gentle, efficient processing, preserving the intricate notes of your perfume.

Seamless Integration into Your Production Line

As a provider of complete production line equipment, YUANYANG offers more than just a standalone perfume filler. We deliver integrated solutions that streamline your entire manufacturing process. From initial mixing and storage tanks to the final filling, capping, labeling, and sealing machines, we provide a holistic approach. This means your YUANYANG perfume filler can be seamlessly combined with our vacuum emulsifying mixers, ensuring your fragrance is perfectly prepared before bottling, and then efficiently packaged. Our commitment to one-stop installation support and full set of turnkey services ensures a smooth setup and operation, reducing complexities and accelerating your time to market.

Reliability and Global Compliance You Can Trust

Your investment in a YUANYANG perfume filler is an investment in reliability and peace of mind. Our machines are backed by our reputation as an industry leader, and proudly carry multiple CE certifications. While CE certification signifies safety and health compliance for the EU market, it underscores our commitment to rigorous manufacturing standards and product integrity. Furthermore, we empower your team with free technical training to ensure optimal performance and longevity of your equipment, reinforcing our dedication to your success.

Partner with a World-Class Manufacturer

YUANYANG's vision is to become the best industrial mixer and agitator manufacturer in the world, and our comprehensive range of equipment, including advanced perfume fillers, reflects this ambition. When you choose YUANYANG, you choose a partner dedicated to delivering superior performance, innovative solutions, and unwavering support. Visit (https://www.yuanymachinery.com/) to explore how our perfume filler machines and complete production lines can transform your fragrance manufacturing.

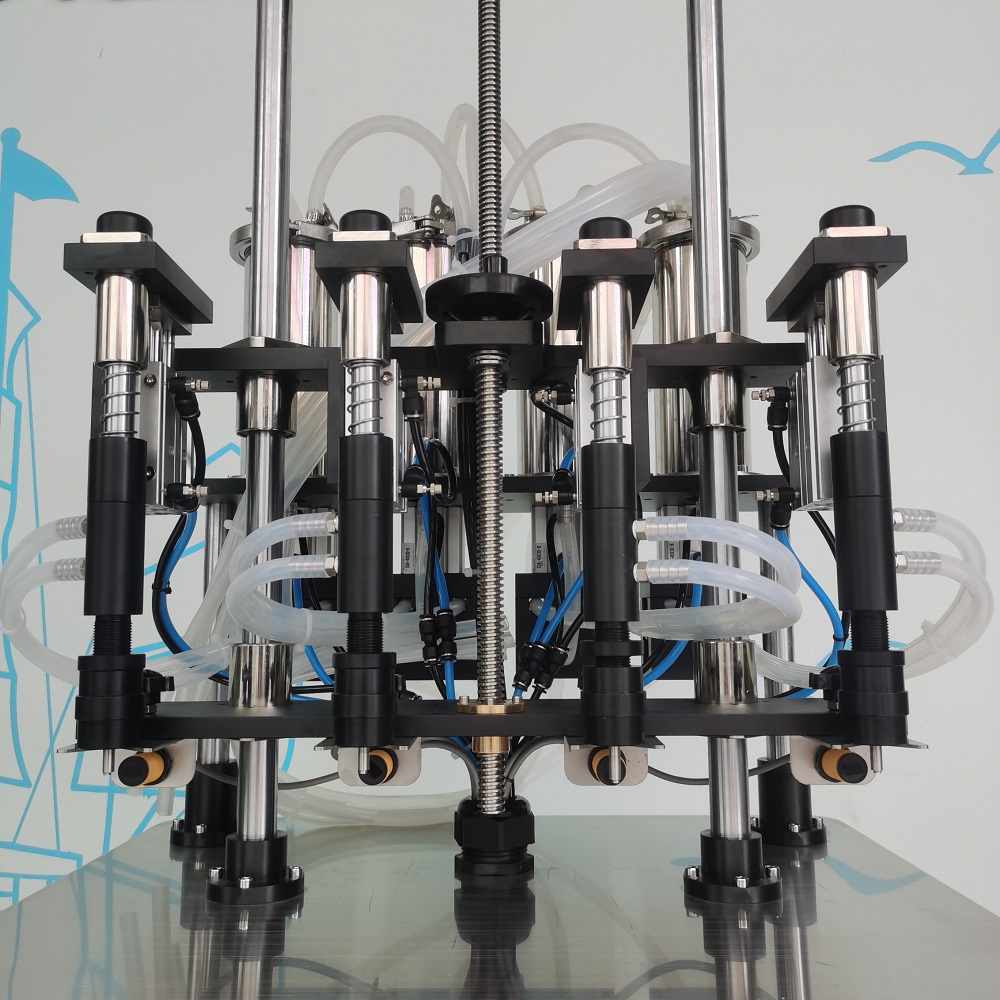

Perfume filler Display

How long does it take to produce the ribbon blender powder machines?

The leading time is about 20-30 days. To ensure quality, the ribbon powder mixer is worth the wait.

Do you supply a complete set of liquid soap production line?

Yes, we supply the complete set of liquid soap production line, such as water treatment, liquid soap making machine, transfer pumps, storage tanks, filling machine, capping machine, sealing machine and labeling machine, and coding machine.

Do you have semi automatic auger filling machine also? I have a limit budget.

Yes, both automatic type and semi automatic type are available, clients can choose the type according to budget and actual needs.

Can you add a mixing function for the tank with heater?

Sure, the cooling tank or heating tank can be customized with top mixing such as paddle, or frame, or scrapers. And client can choose a fixed speed 60rpm, or standard 0-60 rpm with speed adjustment, or customize other speed.

Can the control panel be customized to be hung on the wall?

Yes, we customize a separated control panel which can be moved and installed on the wall or other places.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery