YUANYANG Reverse Osmosis Water Treatment Systems

Reverse Osmosis Water Treatment System

Advanced Purification for Industrial Excellence

YUANYANG’s reverse osmosis water treatment systems are engineered to deliver ultra-pure water across diverse industrial applications. Utilizing semi-permeable membranes, our systems effectively remove up to 99% of dissolved salts, particles, bacteria, and impurities, ensuring optimal process performance and product quality.

Custom Solutions for Every Factory

Whether you operate in food processing, pharmaceuticals, cosmetics, or electronics manufacturing, our reverse osmosis water treatment systems can be tailored to match your facility's unique needs. From compact units for small batches to integrated modules for complete production lines, YUANYANG delivers scalable solutions that fit seamlessly with your existing operations.

Reliable Performance and Easy Maintenance

Our water treatment systems are built with high-quality materials and backed by CE certification for added safety. Each unit is designed for easy operation and low maintenance, reducing downtime and operating costs. Comprehensive training and turnkey installation support ensure a hassle-free experience from inquiry to production.

One-Stop Support and Technical Service

As a leading industrial mixer and blender manufacturer, YUANYANG not only provides top-of-the-line reverse osmosis water treatment systems but also offers full technical support, free training, and expert guidance for system setup and integration. Benefit from our one-stop service to streamline your water purification process and maximize productivity.

Partner with a Trusted Industry Leader

Since 2008, YUANYANG has been the trusted partner for global industry leaders seeking exceptional reverse osmosis water treatment solutions. Contact us today to discuss your water purification needs and discover why YUANYANG stands out in quality, service, and professional expertise.

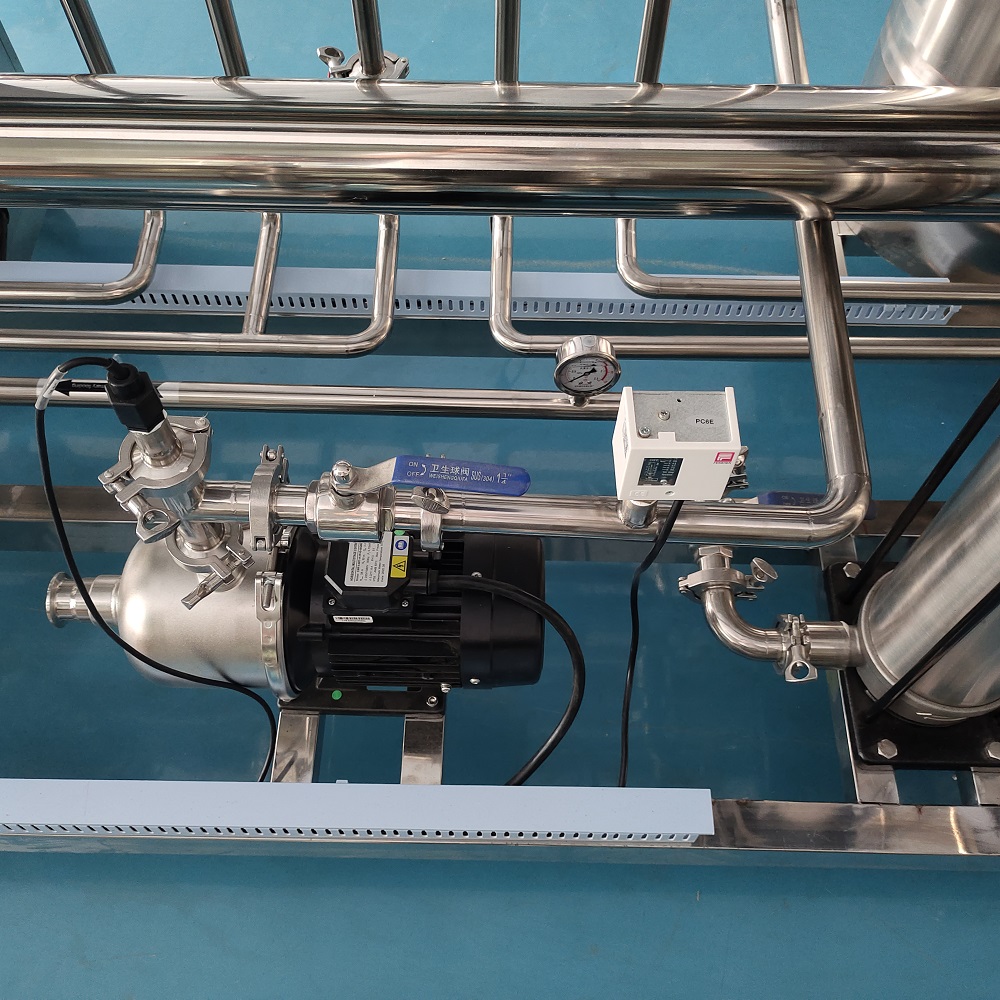

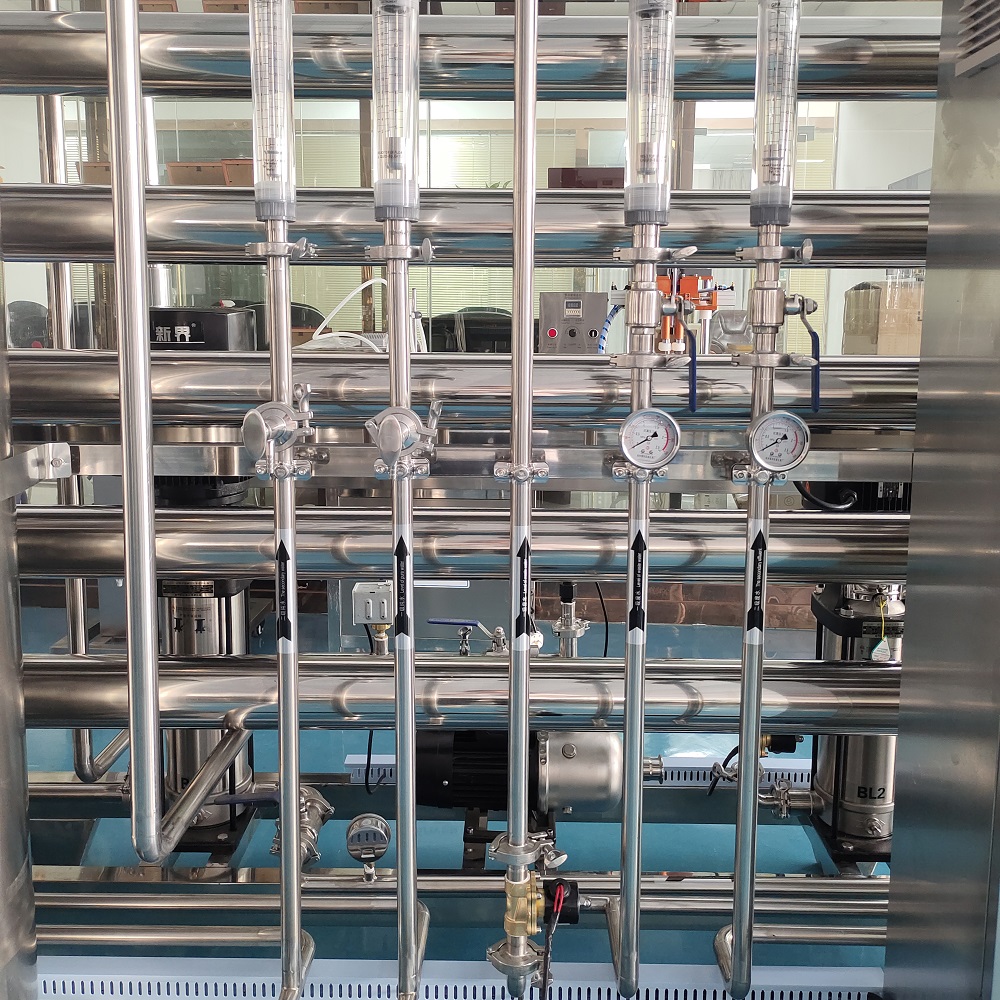

reverse osmosis water treatment system Display

Does it must need an air compressor to operate?

Yes, this semi automatic capper machine requires an air compressor. We can also call it pneumatic capping machine.

Is conveyor equipped together with the filling machine for powder?

Yes, the automatic powder filler machine is equipped with conveyor, which can be connected with other machines such as bottle sorting tables, capping machine, labeling machine and so on.

Do you provide installation and operation training?

Yes, we offer detailed training during installation and commissioning to ensure operators are proficient in using the equipment.

Can I customize stainless steel 316 materials for the dispersing machine?

Yes, we customize materials upon requirement.

What is the production capacity range of the equipment?

Our equipment has a wide range of production capacity options, which can be customized according to specific requirements.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery