Vacuum Emulsifying Mixer Machine - Advanced Industrial Mixing Solutions by YUANYANG

Vacuum Emulsifying Mixer Machine: Precision and Efficiency for Industrial Mixing

Introduction to Vacuum Emulsifying Mixer Machine

The vacuum emulsifying mixer machine is a critical component in modern industrial mixing processes. Designed to blend, emulsify, and homogenize materials under vacuum, this machine ensures superior product consistency by removing air bubbles and preventing contamination. YUANYANG, a leading Chinese manufacturer, offers advanced vacuum emulsifying mixers tailored to diverse industries such as cosmetics, pharmaceuticals, food, and chemicals.

YUANYANG's Expertise and Product Range

Since 2008, YUANYANG has specialized in manufacturing industrial mixers and complete production line equipment, including vacuum homogenizers, high shear mixers, and various vacuum mixers. Our vacuum emulsifying mixer machines integrate cutting-edge technology with practical design to deliver optimal mixing performance, enhanced durability, and precise temperature control.

Key Features and Benefits of Our Vacuum Emulsifying Mixer Machine

- Efficient Vacuum System: Removes trapped air and gases, preventing oxidation and improving product quality.

- High Shear Emulsification: Produces stable emulsions with uniform particle size distribution, ideal for creams and lotions.

- Safe and Certified: YUANYANG products come with multiple CE certifications ensuring compliance with safety and health standards.

- Comprehensive Support: We provide free technical training, turnkey installation, and after-sales services to guarantee smooth operation.

Why Choose YUANYANG Vacuum Emulsifying Mixer Machines?

Choosing YUANYANG means partnering with a trusted manufacturer committed to innovation and quality. Our vacuum emulsifying mixers promote consistent production efficiency, reduce downtime, and improve product stability, making them the ideal choice for businesses looking to scale operations reliably and safely. With our full service capability and extensive industry experience, YUANYANG strives to be your best industrial mixer and agitator partner worldwide.

Explore more at YUANYANG Official Website and experience the future of industrial mixing technology today.

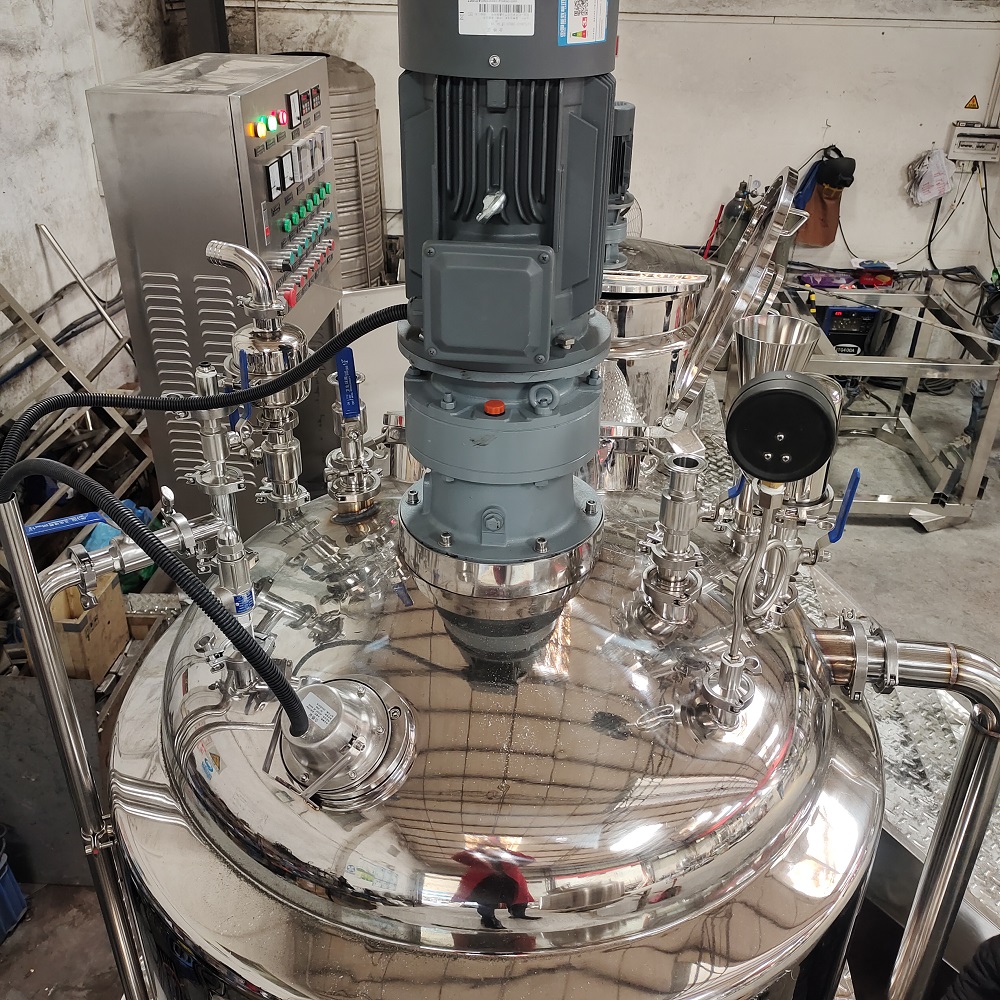

vacuum emulsifying mixer machine Display

Do you have other types of labeling machine?

Yes, there are several types of labeling machine, including semi-automatic labeling machine, automatic labeling machine, round bottle labeling machine, flat labeling machine, double sides labeling machine, square bottle labeling machine.

What minimum caps size can the desktop capping machine be suit for?

The minimum cap size is 20mm, it is recommend to send caps to test if it is around 20mm.

Can Yuanyang's chemical equipment be customized?

Yes, we offer customization services for our equipment to meet your specific production needs.

Do you have a vibratory cap feeding machine for the automatic capping machine?

Yes, we provide vibratory cap feeder or elevator type cap feeder to sort caps. The cap feeder machine has to be customized according cap shape and size, like pump head with straw, metal caps,plastic caps and so on.

What’s the weight range can the automatic liquid packing machine pack?

Filling weight of this auto plastic packing machine should be less than 100g for this model. There will be different model for 100-500g or 500-1000g.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery