High-Quality Cosmetic Mixing Tanks by YUANYANG for Efficient Production

Professional Cosmetic Mixing Tanks for Superior Product Quality

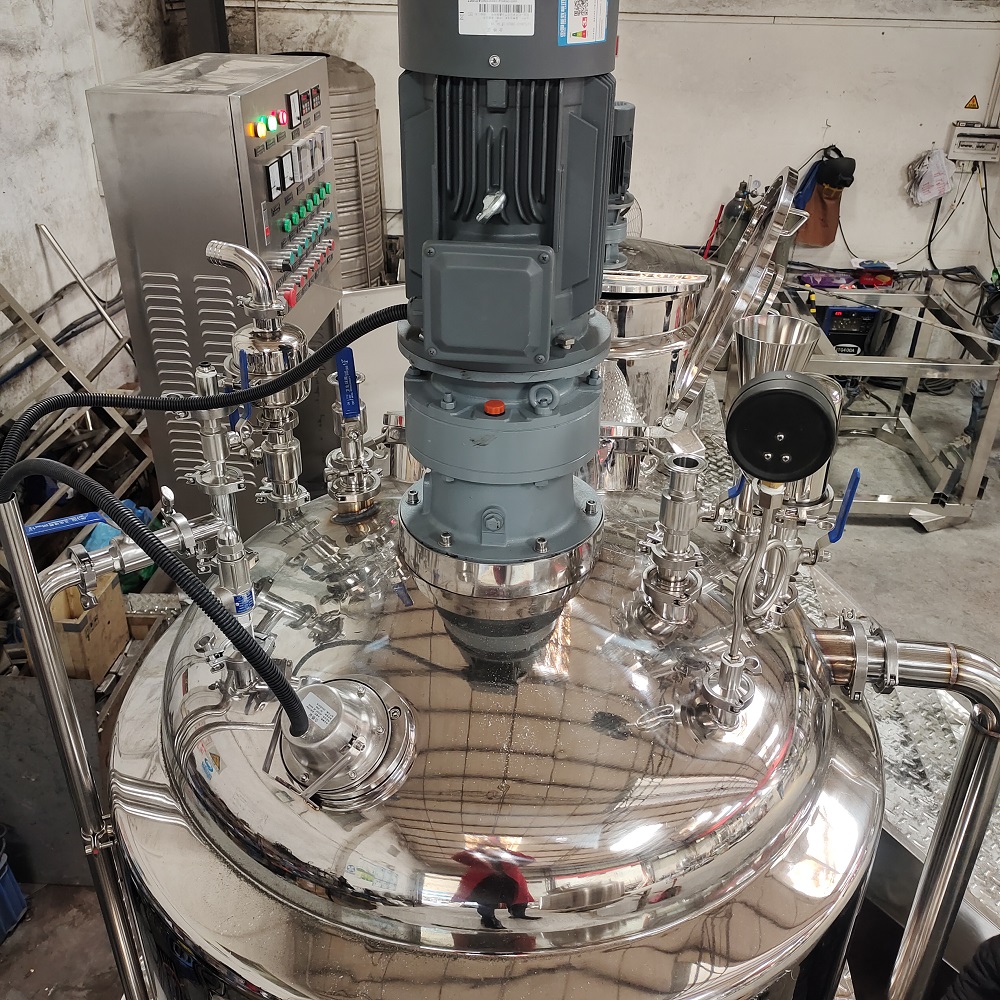

YUANYANG, a leading industrial mixer manufacturer in China since 2008, specializes in high-performance cosmetic mixing tanks engineered to meet the strict standards of the cosmetic industry. Our tanks are built to deliver efficient, uniform mixing, helping manufacturers achieve consistent product texture and quality.

Advanced Technology and Reliable Performance

Our cosmetic mixing tanks incorporate vacuum emulsifying and high shear mixing technology, ensuring thorough blending of viscous creams, lotions, and other formulations. Designed with durable materials and hygienic features, these tanks comply with CE safety certifications, making them ideal for large-scale cosmetic production.

Turnkey Solutions with Comprehensive Support

YUANYANG offers complete production line equipment integration, including mixing tanks, storage, filling, and labeling machines, coupled with free technical training and installation support. Our commitment to turnkey services ensures minimal downtime and optimized workflow for your cosmetic manufacturing process.

Why Choose YUANYANG Cosmetic Mixing Tanks?

Choosing YUANYANG means investing in technology backed by years of expertise and multiple CE certifications. Our cosmetic mixing tanks are crafted to enhance productivity, maintain product consistency, and meet international safety standards, giving your business a competitive edge.

Explore YUANYANG’s cosmetic mixing tanks and elevate your cosmetic production efficiency today.

cosmetic mixing tank Display

What’s the thickness of the vacuum mixer?

The thickness depends on the machine type, capacity of the tank, and the function. For example the standard 500L vacuum homogenizer tank electric heating with double jackets, there are three layers. The inner layer is 5mm, middle layer is 4mm, the outer layer is 2mm. If clients has special requirement, we can customize accordingly.

Can it close glass bottles?

As long as the glass bottle has screw cap, the capping machine can close its cap, although the machine is often called plastic capping machine.

Do you offer warranties and after-sales service?

Yes, we provide warranties and comprehensive after-sales support to ensure uninterrupted production and equipment reliability.

What types of pharmaceutical raw materials can Yuanyang’s equipment handle?

Our equipment can handle a wide range of pharmaceutical raw materials, including liquids, creams, powders, capsule ingredients, and viscous or high-viscosity materials, suitable for various formulations and production processes.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery