YUANYANG: Advanced Vacuum Homogenizer Cream Mixers for Superior Production

Elevate Your Production with YUANYANG Vacuum Homogenizer Cream Mixers

In today's competitive market, achieving unparalleled product quality and manufacturing efficiency is paramount. For industries demanding exquisite textures, perfect emulsions, and contamination-free processing – from cosmetics and pharmaceuticals to food and chemicals – the right mixing technology makes all the difference. At YUANYANG, a leading manufacturer of industrial mixers and agitators since 2008, we specialize in providing state-of-the-art vacuum homogenizer cream mixers designed to redefine your production standards.

Unmatched Precision for Perfect Emulsions

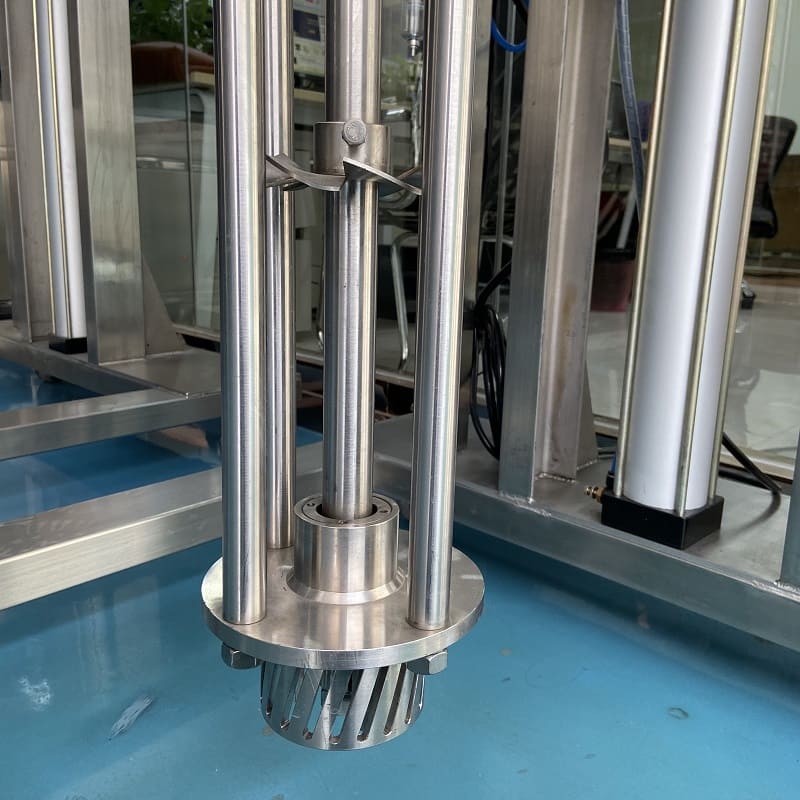

Our vacuum homogenizer cream mixer category represents the pinnacle of mixing technology. These sophisticated machines are engineered to create stable, homogeneous emulsions and suspensions with exceptional fineness and consistency. By operating under vacuum, our mixers effectively eliminate air bubbles, prevent oxidation, and ensure a smooth, refined product free from imperfections. Coupled with powerful high-shear homogenization and efficient scraping mechanisms, YUANYANG vacuum homogenizers guarantee superior particle size reduction and uniform dispersion, making them ideal for high-viscosity products like creams, lotions, ointments, and pastes.

Why Choose YUANYANG for Your Mixing Solutions?

As one of China's foremost manufacturers, YUANYANG brings over a decade of expertise to your production line. We don't just supply equipment; we provide complete, integrated solutions. Our extensive product range includes not only advanced vacuum homogenizers and vacuum emulsifying mixers but also complementary equipment such as storage tanks, filling machines, and water treatment systems – delivering a full production line setup. We pride ourselves on offering free technical training and one-stop installation support, ensuring a seamless, turnkey experience from concept to operation. Moreover, YUANYANG's commitment to quality and safety is underscored by multiple CE certifications, affirming our adherence to stringent European health and safety standards.

Advanced Technology for Optimal Performance

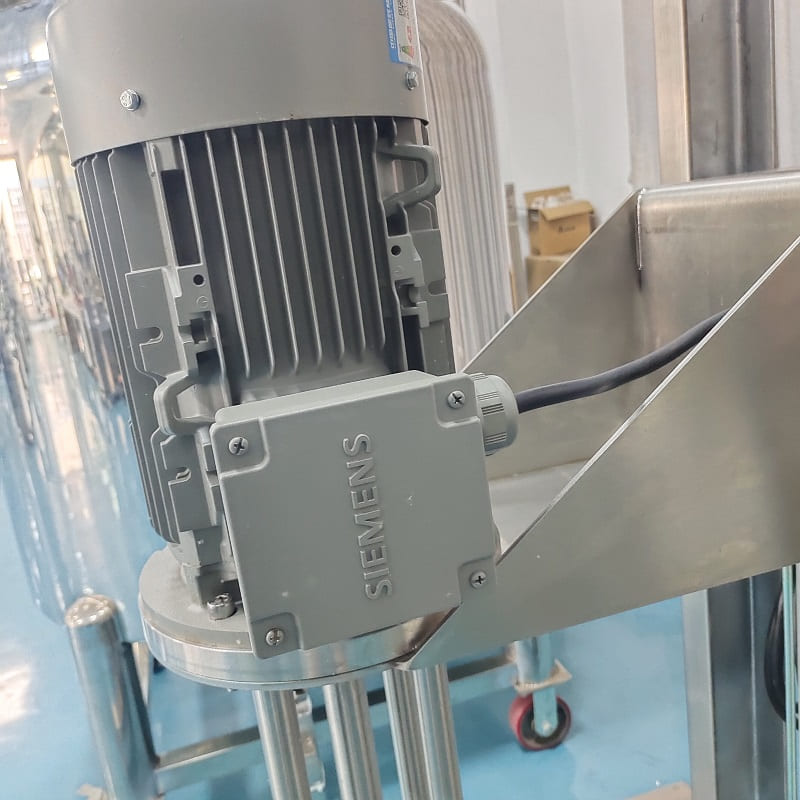

YUANYANG's cream mixer solutions are built with robust materials and cutting-edge design, ensuring durability and reliability for continuous operation. Our advanced control systems provide precise management of mixing speed, temperature, and vacuum levels, allowing for repeatable processes and consistent product quality batch after batch. Whether you require a high shear mixer for intensive blending or a vacuum emulsifying mixer for delicate formulations, our technology is optimized for peak performance, energy efficiency, and ease of cleaning, ly enhancing your operational output and reducing production costs.

Partner with YUANYANG and experience the difference that superior engineering and dedicated support can make. Our vision is to become the best industrial mixer and agitator manufacturer in the world, and we achieve this by empowering your success. Explore our range of industrial mixers and discover how our advanced solutions can transform your manufacturing process. Visit yuanymachinery.com today to learn more.

vacuum homogenizer cream mixer Display

Do you have a water pump with flow meter installed for the shampoo mixer machine?

Yes, water pump with flow meter can be added upon requirements.

Can the capping head lift up and down?

Yes, the servo capping machines have servo motors for adjustment of capping height, can achieve lift up and down directly by touch screen control.

Do you supply steam generator and provide steam and cooling pipes together for the mixing tank with homogenizer machine?

If the mixing tank is with steam heating, we will help to supply steam generator and provide steam and cooling pipes. But this is an optional choice. Client can prepare by steam generator by himself. The steam pipe is usually quoted separately.

What material can the piston filling machine fill?

The piston filler can fill a variety of viscous liquids and pastes, such as laundry detergent, shampoo, hair conditioner, toothpaste, gel water, aloe vera gel, lotion and other washing and care products, honey, loquat paste, mother-herb paste, ketchup, salad dressing and other food.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery