Automatic Screw Capping Machine

Automatic Screw Capping Machine – Precision & Efficiency for Industrial Packaging

What Is an Automatic Screw Capping Machine?

An automatic screw capping machine is designed to securely fasten screw caps onto bottles with high speed and accuracy. Ideal for pharmaceuticals, cosmetics, food, and chemical industries, it ensures leak-proof sealing while minimizing human error.

Key Benefits of YUANYANG’s Automatic Capping Machines

- High-Speed Performance: Processes hundreds of bottles per minute, boosting production efficiency.

- Versatile Compatibility: Works with plastic, glass, and metal containers of varying sizes.

- Durable & Low-Maintenance: Built with industrial-grade materials for long-term reliability.

- CE-Certified Safety: Compliant with EU standards for safe operation.

Industries That Benefit from Automatic Screw Capping

- Pharmaceuticals: Ensures tamper-proof sealing for medicine bottles.

- Cosmetics & Personal Care: Maintains product integrity with airtight closures.

- Food & Beverage: Prevents contamination with secure screw caps.

- Chemicals & Liquids: Reduces spillage and evaporation risks.

Why Choose YUANYANG’s Capping Solutions?

As a leading China-based industrial mixer and blender manufacturer, YUANYANG provides turnkey packaging solutions, including:

- Customizable capping machines for unique production needs.

- Free technical training & installation support.

- CE-certified machinery for European market compliance.

Seamless Integration with Full Production Lines

Pair our automatic screw capping machine with YUANYANG’s filling, labeling, and sealing systems for a complete packaging workflow. Our one-stop OEM services ensure hassle-free setup and optimization.

Get a Reliable Capping Solution Today

Upgrade your packaging line with YUANYANG’s high-performance automatic screw capping machine—engineered for speed, precision, and durability. Contact us for a custom quote!

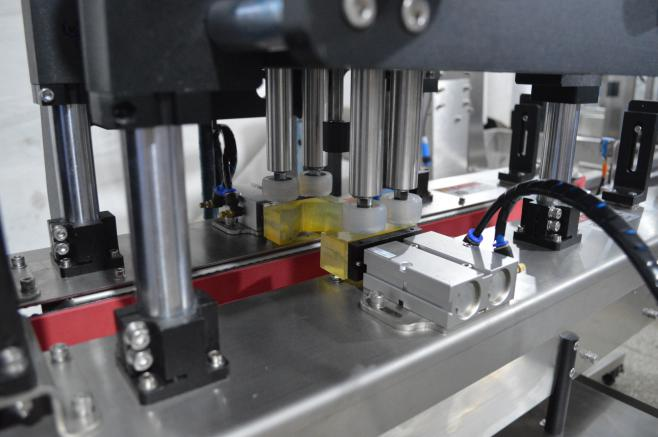

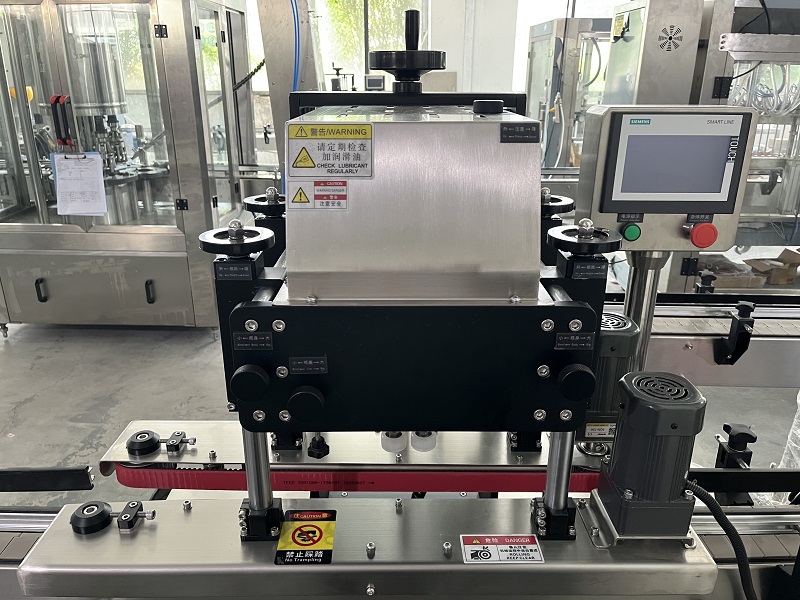

automatic screw capping machine Display

What minimum and maximum caps size can the bottle capper machine be suit for?

The cap diameter of standard 4 wheels capping machine is 20-75mm, but can be slightly customized according real cases.

What material can the piston filling machine fill?

The piston filler can fill a variety of viscous liquids and pastes, such as laundry detergent, shampoo, hair conditioner, toothpaste, gel water, aloe vera gel, lotion and other washing and care products, honey, loquat paste, mother-herb paste, ketchup, salad dressing and other food.

Can I visit your factory?

Yes,welcome to visiting our factory.Our factory is located in Guangzhou, China. You could visit us by taxi or by metro. Our company can pick you up. Please contact our customer service for appointment in advance.

How many bottles can the cream filler fill per hour?

The filling speed is affected by many factors, such as the materials thickness, viscosity, operation speed by staffs, pneumatic speed adjustment, filling volume, pressure. The filling speed varies from 500-2400 bottles per hour.

What’s the maximum height that the lid can lift up to? And how high it is when cover closed?

The dimension is different for different capacity. For example, the 500L height is 2.48m when cover closed, the height is 3.6m when cover lift up.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery