YUANYANG Vacuum Mixer – Advanced Industrial Mixing Solutions

YUANYANG Vacuum Mixer: Superior Industrial Mixing Technology

YUANYANG stands as a pioneer in manufacturing top-tier industrial mixers, including vacuum mixers tailored for demanding applications. Our vacuum mixers integrate vacuum homogenizing and emulsifying technologies to ensure precise, uniform mixing in diverse industries such as cosmetics, pharmaceuticals, and food processing.

Advanced Mixing Performance with Vacuum Technology

Our vacuum mixer line eliminates air bubbles and oxidation during mixing, significantly enhancing product stability and quality. YUANYANG vacuum mixers feature high shear and homogenizing mechanisms that achieve consistent emulsification and fine particle distribution, boosting productivity and product performance.

Complete Turnkey Solutions and Technical Support

Since 2008, YUANYANG has provided comprehensive production line equipment, including vacuum mixers, storage tanks, filling and capping machines. We offer free technical training and on-site installation assistance, ensuring seamless integration and optimized operation of your vacuum mixer systems.

Certified Quality and Safety Assurance

With multiple CE certifications, YUANYANG vacuum mixers comply with stringent EU safety and health standards, giving customers peace of mind. Our commitment to reliability and durability makes YUANYANG a trusted choice for global industrial mixer needs.

Why Choose YUANYANG Vacuum Mixers?

- Innovative vacuum emulsifying and homogenizing technology

- Energy-efficient and easy to operate

- Comprehensive after-sales and technical training

- Global certifications ensuring safety compliance

- Solutions customized to your production requirements

Explore YUANYANG's vacuum mixers today to enhance your manufacturing efficiency and product excellence. Visit YUANYANG official website to learn more.

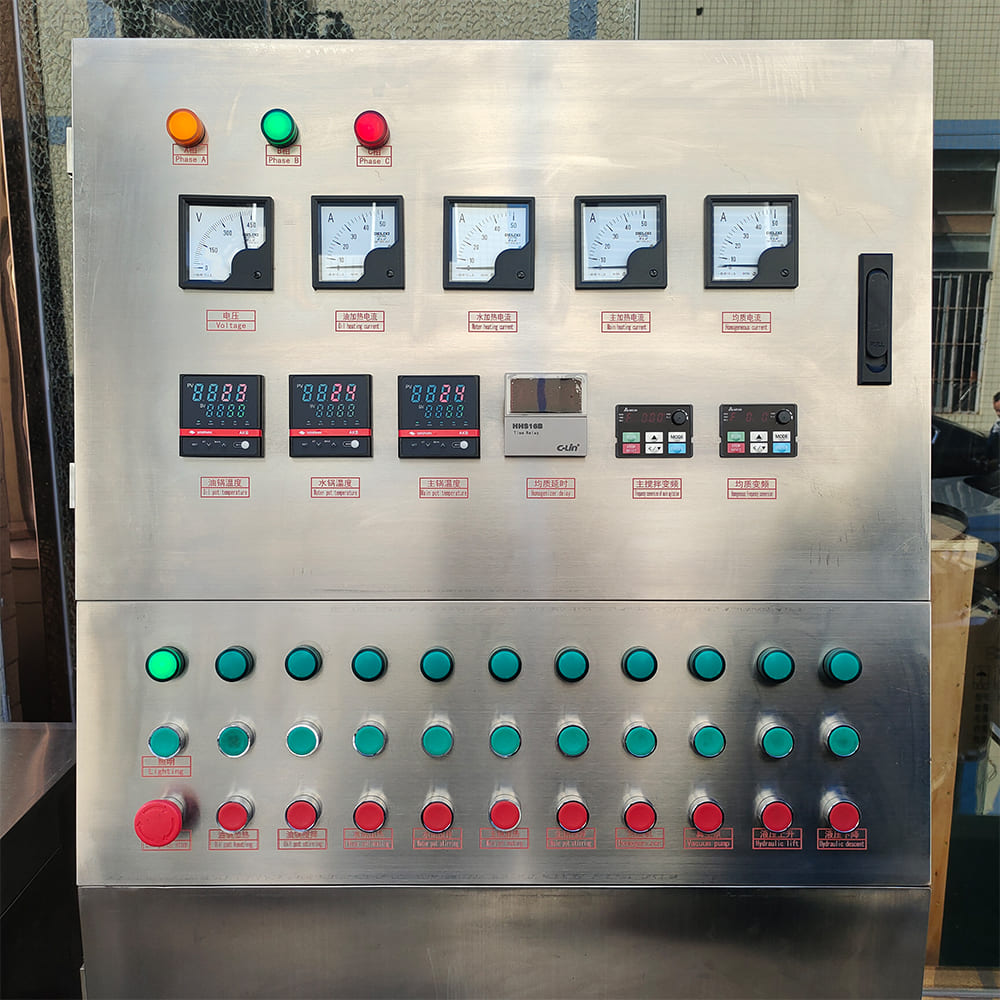

vacuum mixer Display

What type of film can the bottle sealer machine work for?

The sealing machine is mainly used for heating and sealing polyolefin (such as polyethylene, polypropylene, etc.) as the inner layer of composite film material sealing.

What’s the working principle of high shear homogenizer?

The shear mixer mainly through the high-speed relative rotation of the rotor and the stator to produce a strong shear force to achieve the refinement and homogenization of the material.

What’s the operation process?

Operation process: put the bottle on track- > step on the foot switch - > automatically taking the bottle in - > Automatically labeling - > Automatically taking the labeled bottle out.

Can you add load cell for material weighing for the ribbon mixer machine?

Yes, load cell is an optional choice. It is usually installed on feet. And there will be indicator on the control panel.

The capping wheel is a little high for the small bottles, do you have solutions?

Yes, we have designed cylinder type for mini bottles.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery