YUANYANG Water Treatment Equipment

Water Treatment Equipment: Optimize Your Production with YUANYANG

Comprehensive Water Purification Solutions

YUANYANG offers state-of-the-art water treatment equipment designed to deliver highly purified water, essential for industrial production. Our systems integrate advanced filtration, softening, and sterilization technologies, ensuring every drop meets stringent industry standards. Whether you require water for mixing, processing, or cleaning, our equipment guarantees superior reliability and precision.

Customized for Industrial Production Lines

Our water treatment solutions are engineered to seamlessly fit into your existing production lines. YUANYANG understands the unique requirements of mixing, blending, and filling processes. That’s why we offer customizable options—tailored capacity, automation, and configurations—to ensure optimal water quality throughout the manufacturing cycle.

CE-Certified Quality and Safety

YUANYANG’s water treatment equipment is CE-certified, underscoring our commitment to safety and compliance with European market standards. Our efficient systems minimize downtime, reduce maintenance costs, and enhance your production’s overall efficiency—making them a trusted choice for manufacturers worldwide.

One-Stop Support and Turnkey Services

From project consultation to installation and training, YUANYANG provides comprehensive one-stop support. Our expert team offers free technical training, ensuring your staff is fully equipped to operate and maintain our advanced water treatment equipment. Plus, with our turnkey service solutions, the setup process is fast, smooth, and worry-free.

Boost Productivity with YUANYANG

Upgrade your facility with YUANYANG’s water treatment equipment and experience reliable quality, safety, and complete technical support. Trust a leading China-based manufacturer with over 15 years of industry expertise to power your production with clean, consistent water supply.

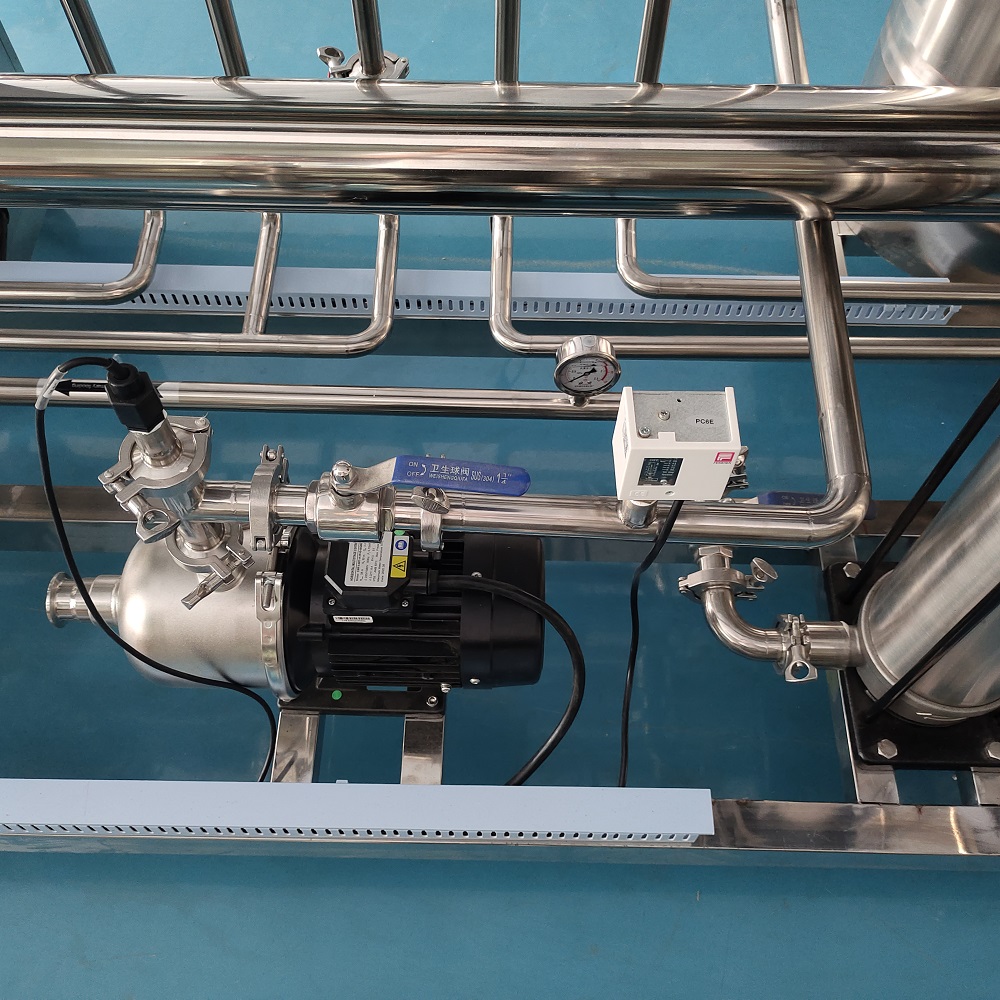

water treatment equipment Display

What material can the piston filling machine fill?

The piston filler can fill a variety of viscous liquids and pastes, such as laundry detergent, shampoo, hair conditioner, toothpaste, gel water, aloe vera gel, lotion and other washing and care products, honey, loquat paste, mother-herb paste, ketchup, salad dressing and other food.

Do you offer customization services?

Yes, we support personalized design of equipment and adjustments based on specific customer needs.

What’s the filling range of the powder dosing machine?

The filling range of the semi auto powder filling machines is: 10-5000g. But we need to customize according to specific weight that clients plan to pack. The screw model will be different.

Is the servo capper be compatible for different bottle size and shapes?

Yes, the capping wheels can be adjusted higher or lower for different bottle height. The distance between wheels can be wider or closer for different cap diameter.

How do I know the water conductivity?

The reverse osmosis water filter machine can display both raw water conductivity and output water conductivity.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery