200L Vacuum Emulsifying Mixer - High Efficiency Industrial Mixing Solutions

High Quality 200L Vacuum Emulsifying Mixer by YUANYANG

Advanced Emulsification Technology

The 200L vacuum emulsifying mixer from YUANYANG offers industry-leading emulsification and homogenization capabilities for pharmaceuticals, cosmetics, food, and chemical production. With a strong vacuum system, it effectively removes air bubbles, ensuring a uniform and stable mixture with enhanced texture and quality.

Robust Design and High Efficiency

Built with durable materials and state-of-the-art high shear mixing technology, the 200L model delivers consistent performance and longevity. Its optimized mixing blades and vacuum environment enable rapid emulsification and smooth integration of even the most challenging raw materials.

Comprehensive Turnkey Solutions

YUANYANG provides not only the 200L vacuum emulsifying mixer but also offers full production line equipment, including storage tanks, filling machines, and capping machines, supported by free technical training and one-stop installation services. This ensures seamless integration and immediate productivity boost at your facility.

Trusted Safety & Quality Assurance

Backed by multiple CE certifications, the 200L vacuum emulsifying mixer complies with EU safety and health standards, reflecting YUANYANG's commitment to manufacturing secure and reliable industrial mixers. Choose YUANYANG for proven expertise since 2008 and elevate your production capabilities.

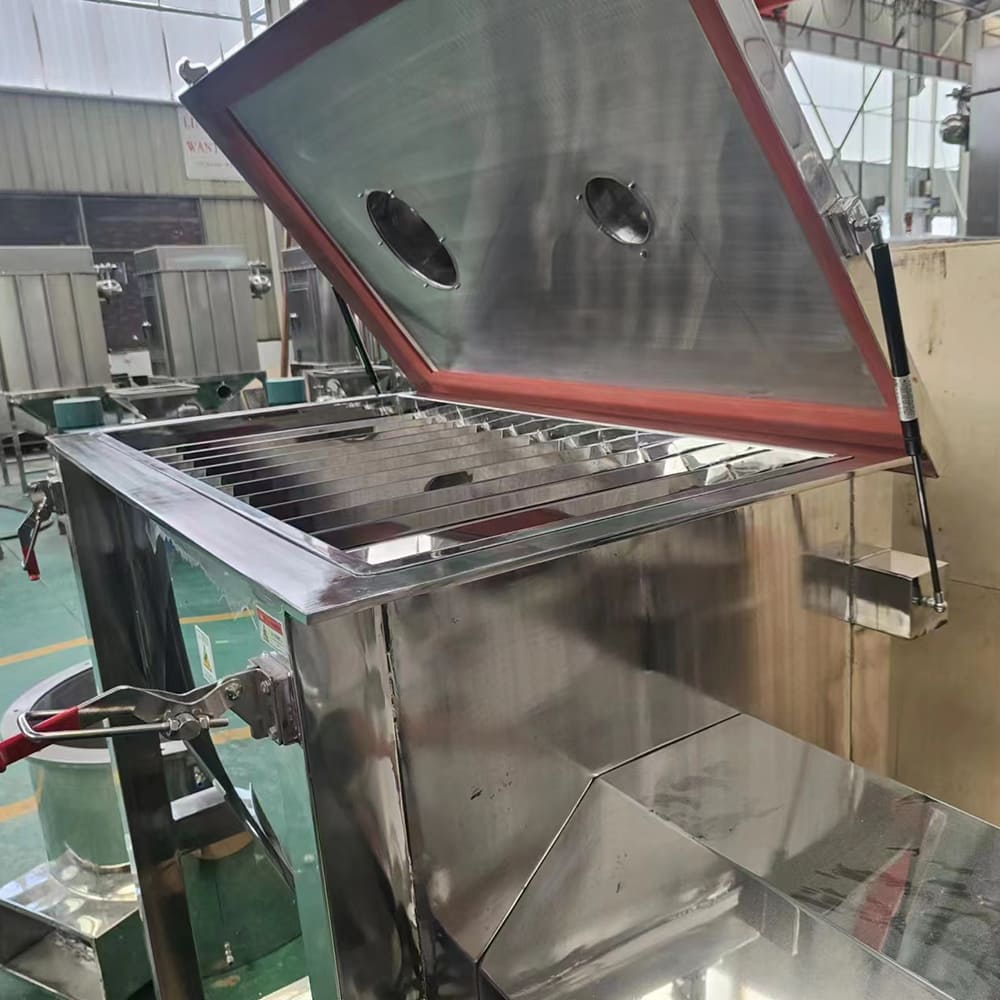

200l vacuum emulsifying mixer Display

Is the sachet packing machine equipped with conveyor ?

Yes, the standard sachet packaging machine is with a conveyor for transferring the finished bags.

What types bottles are suitable for this label dispenser?

It is suitable for single side and double side labeling of flat bottles, round bottles and square bottles, such as shampoo, laundry detergent flat bottles, lubricating oil flat bottles, hand sanitizer round bottles and other double side labeling, both sides of the same labeling, double labeling improves production efficiency, and is widely used in daily chemical, cosmetics, petrochemical, pharmaceutical and other industries.

What’s the date printing, steel printing or coding?

There are standard steel date printing on the automatic packaging machine, if clients needs coding type, just tell us to add an extra coding device.

How long to replace the reverse osmosis membrane and pvc film?

Reverse osmosis membranes are generally recommended to be replaced every year. But it is not a fixed time, the period should be considered according to the actual use environment and operating conditions.

PVC film is recommended to replace every two weeks.

Is this storage tank food grade?

Yes, the liquid tank is made of stainless steel 304 or 316L, can store food sauce, mayonnaise, cosmetic cream, lotion, pharmaceutical ointment, other liquids and paste...

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery