High Quality Stainless Mixing Tanks

# Stainless Mixing Tanks: High-Quality Solutions for Industrial Blending

Durable & Hygienic Stainless Steel Construction

Our stainless mixing tanks are crafted from high-grade 304 or 316 stainless steel, ensuring corrosion resistance and long-term durability. Ideal for food, pharmaceutical, and chemical industries, these tanks meet strict hygiene standards while maintaining structural integrity under heavy use.

Precision Mixing for Consistent Results

YUANYANG’s stainless mixing tanks feature advanced agitation systems for uniform blending. Whether handling viscous liquids, powders, or emulsions, our tanks ensure smooth, efficient mixing with minimal product degradation.

Customizable Designs for Every Industry

Need a tailored solution? We offer stainless mixing tanks in various sizes, configurations, and accessories (heating/cooling jackets, CIP systems, etc.). Our engineers work closely with clients to meet specific production requirements.

CE-Certified & Safety-Compliant

All YUANYANG stainless mixing tanks comply with CE standards, ensuring safe operation in the EU market. Our tanks undergo rigorous testing for performance, safety, and environmental compliance.

One-Stop Turnkey Solutions

Beyond stainless mixing tanks, YUANYANG provides complete production lines—from mixing to filling, labeling, and packaging. Benefit from free technical training and seamless installation support.

Why Choose YUANYANG?

- 17+ Years of industrial mixing expertise

- CE-certified for EU compliance

- Custom-engineered solutions

- Full after-sales support

Upgrade your production with YUANYANG’s stainless mixing tanks—contact us for a quote today!

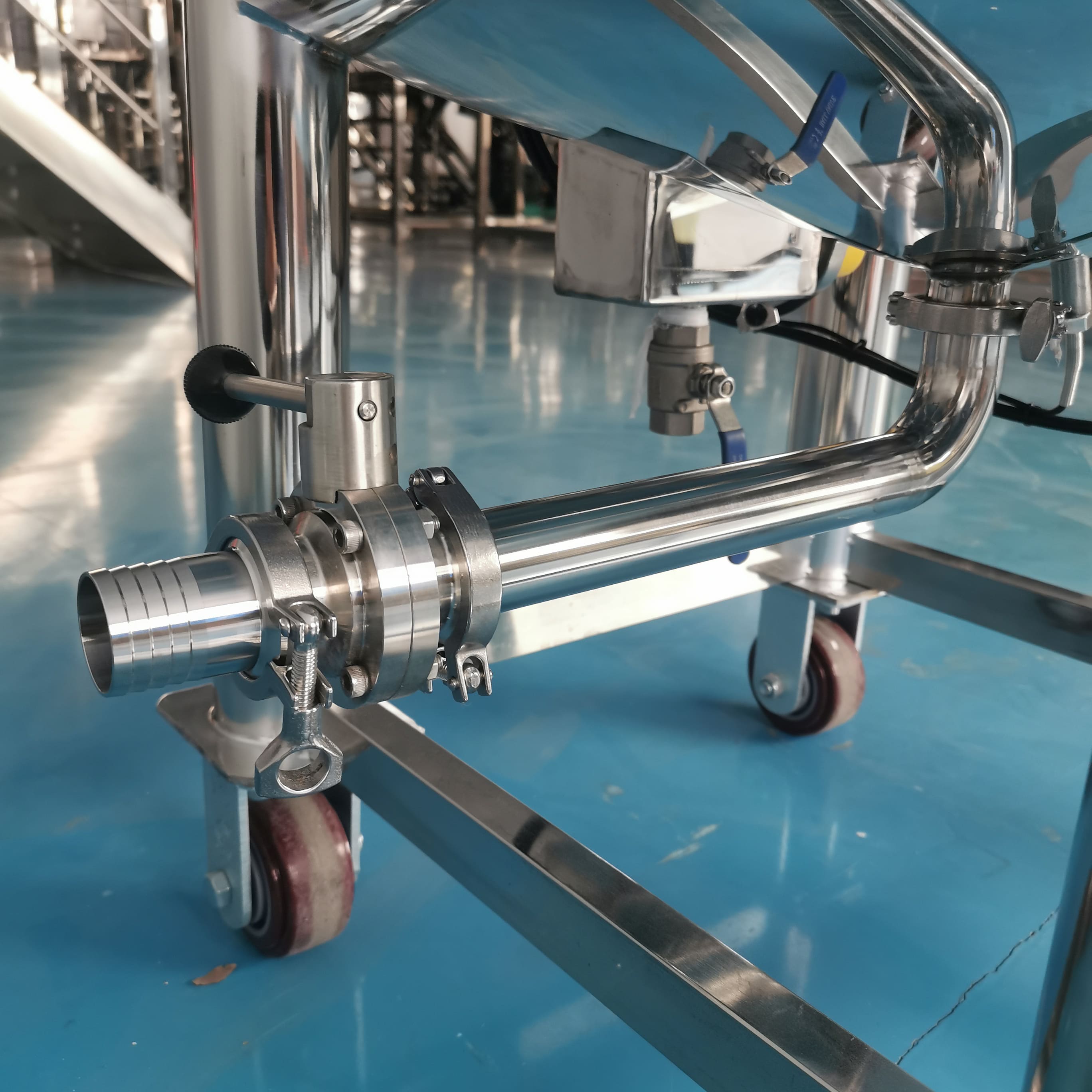

stainless mixing tank Display

Can you customize soap mixer machine accordingly if the ceiling height is limited?

Yes, the tank size will be customized, the top motor can be horizontal to make sure the complete set machine can fit client’s factory.

Is the equipment compliant with environmental standards?

Yes, all our machines meet international environmental standards, reducing emissions and supporting sustainable production.

How to discharge finished products?

Let the liquid products flow down naturally by valve control. Use a transfer pump to convey products to storage tanks in a short time.

How accurate is the filling process?

Our high-precision filling system ensures consistent and accurate filling every time.

Do you also supply the complete powder production line machines?

Yes, we provide a solution including: powder feeding machine, powder mixing machine, and powder packing machine which will be recommended according to how client plans to pack the powder.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery