Semi-Automatic Powder Filling Machines for Sale | YUANYANG

# Semi-Automatic Powder Filling Machines for Sale

High-Quality & Reliable Machines

YUANYANG, a leading China-based manufacturer of industrial mixing and blending equipment, offers a range of robust and efficient semi-automatic powder filling machines. Built for durability and precision, our machines ensure accurate and consistent filling, minimizing waste and maximizing productivity. We utilize high-grade materials and advanced technology to guarantee long-lasting performance.

Versatile Applications & Customization

Our semi-automatic powder filling machines are suitable for various industries and applications, including food, pharmaceutical, chemical, and cosmetic products. We offer customization options to meet your specific production needs and requirements. From container size to filling volume, we work closely with our clients to deliver tailored solutions.

Complete Turnkey Solutions

YUANYANG provides more than just machines. We offer comprehensive turnkey solutions, encompassing installation, technical training, and ongoing support. Our experienced engineers guide you through every step of the process, ensuring a seamless transition and efficient operation. This one-stop service minimizes disruptions and maximizes your return on investment.

CE Certified & Guaranteed Quality

Rest assured, our semi-automatic powder filling machines meet stringent international safety standards, as evidenced by our CE certification. This signifies our commitment to quality and customer safety. We’re confident in the reliability of our equipment and stand behind it with a strong warranty.

Contact Us Today

Ready to improve your powder filling process? Contact YUANYANG today for a quote and to discuss your specific requirements. We’ll help you find the perfect semi-automatic powder filling machine to elevate your production efficiency and profitability.

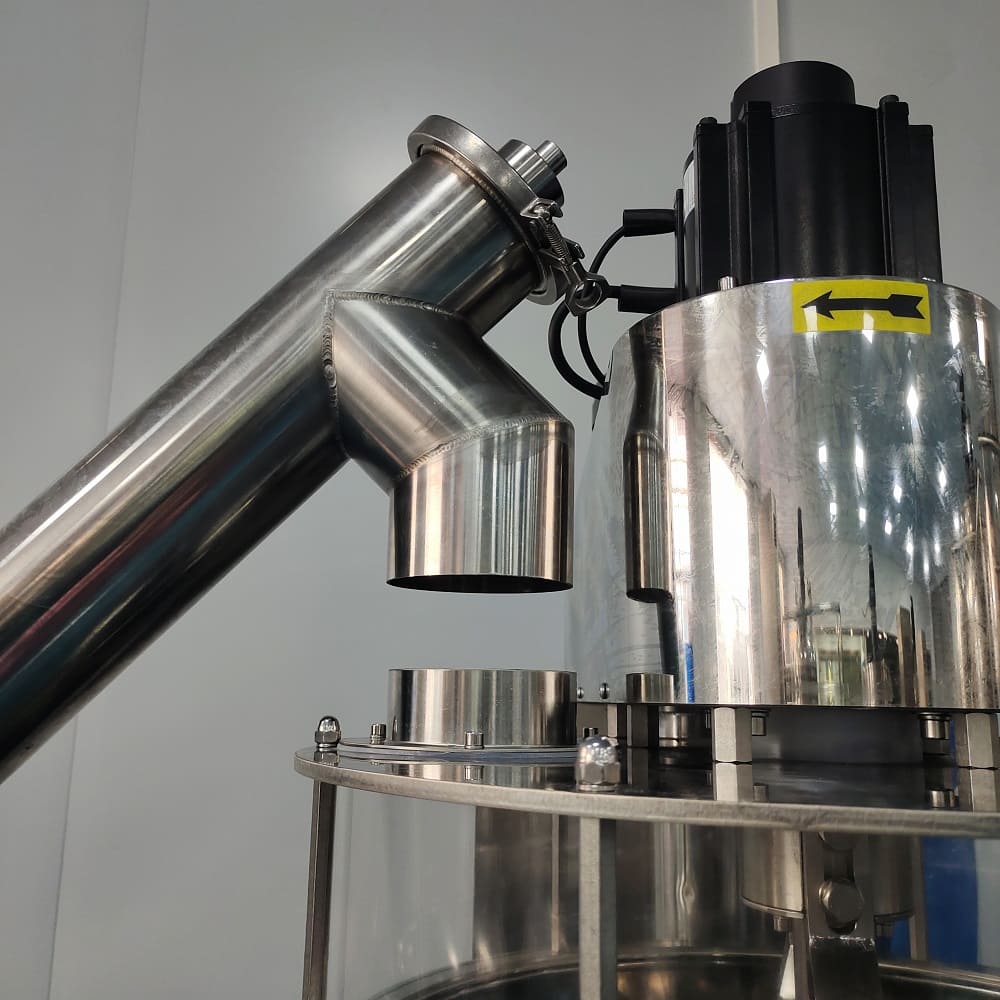

Semi Automatic Powder Filling Machine for sale Display

Is this lid capping machine suitable for different shapes and sizes of bottles/jars?

Yes, the capping wheels can be adjusted higher or lower for different bottle height. The distance between wheels can be wider or closer for different cap diameter.

What is the delivery lead time?

The production and delivery lead time depends on specific customization requirements, generally ranging from 4 to 8 weeks.

Can the upper smaller blade move up or down?

Yes, the extra blades can be flexible fixed higher or lower based on materials depth.

Can you add more layer to filter different sizes for the industrial shaker machine?

Yes, we can customize 1-5 layers according to needs.

What’s the hopper capacity of the feeding machine for powder?

The standard feeder hopper capacity is 150L, can be customized.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery