Elevate Your Dairy Production with YUANYANG Milk Homogenizers

Elevate Your Dairy Production with YUANYANG Milk Homogenizers

At YUANYANG, a leading manufacturer of industrial mixers and agitators since 2008, we understand that achieving unparalleled quality in dairy products begins with precision. Our state-of-the-art milk homogenizers are engineered to transform your raw milk into a perfectly uniform, stable, and visually appealing product, ready to delight consumers.

The Science Behind Perfect Homogenization

Homogenization is a critical process in dairy production, designed to break down fat globules in milk into smaller, evenly dispersed particles. This prevents cream separation, enhances the milk's texture, improves its taste, and significantly extends its shelf life. YUANYANG's milk homogenizers utilize advanced technology to ensure a consistent, fine dispersion, contributing to superior product stability, improved digestibility, and a richer mouthfeel for a wide range of dairy and beverage applications.

YUANYANG's Advanced Milk Homogenizer Technology

Leveraging our extensive expertise in vacuum homogenizers, vacuum emulsifying mixers, and high shear mixers, YUANYANG brings cutting-edge design and robust engineering to our milk homogenizer range. Each unit is built for durability, efficiency, and easy maintenance, ensuring continuous operation and consistent performance. Our homogenizers are designed for precise control over pressure and flow, allowing you to achieve the exact particle size distribution required for your specific product formulations, from fresh milk to creams and even plant-based dairy alternatives.

Comprehensive Solutions for Dairy & Beverage Industries

Beyond individual machines, YUANYANG specializes in providing complete production line equipment. When you choose our milk homogenizer, you're integrating it into a seamless ecosystem. From initial mixing and storage tanks to filling machines, capping machines, labeling, sealing, and even water treatment equipment, we offer a full suite of solutions. This commitment to holistic support, coupled with our free technical training and one-stop installation, exemplifies our promise of providing full-set turnkey services.

Why Choose YUANYANG for Your Homogenization Needs?

YUANYANG is not just a supplier; we are your strategic partner. Our unwavering dedication to quality is underscored by our multiple CE certifications, assuring safety and compliance. With a vision to become the best industrial mixer and agitator manufacturer in the world, we are committed to innovation, customer satisfaction, and delivering reliable, high-performance machinery. Visit our website https://www.yuanymachinery.com/ to learn more about how YUANYANG can elevate your dairy production capabilities.

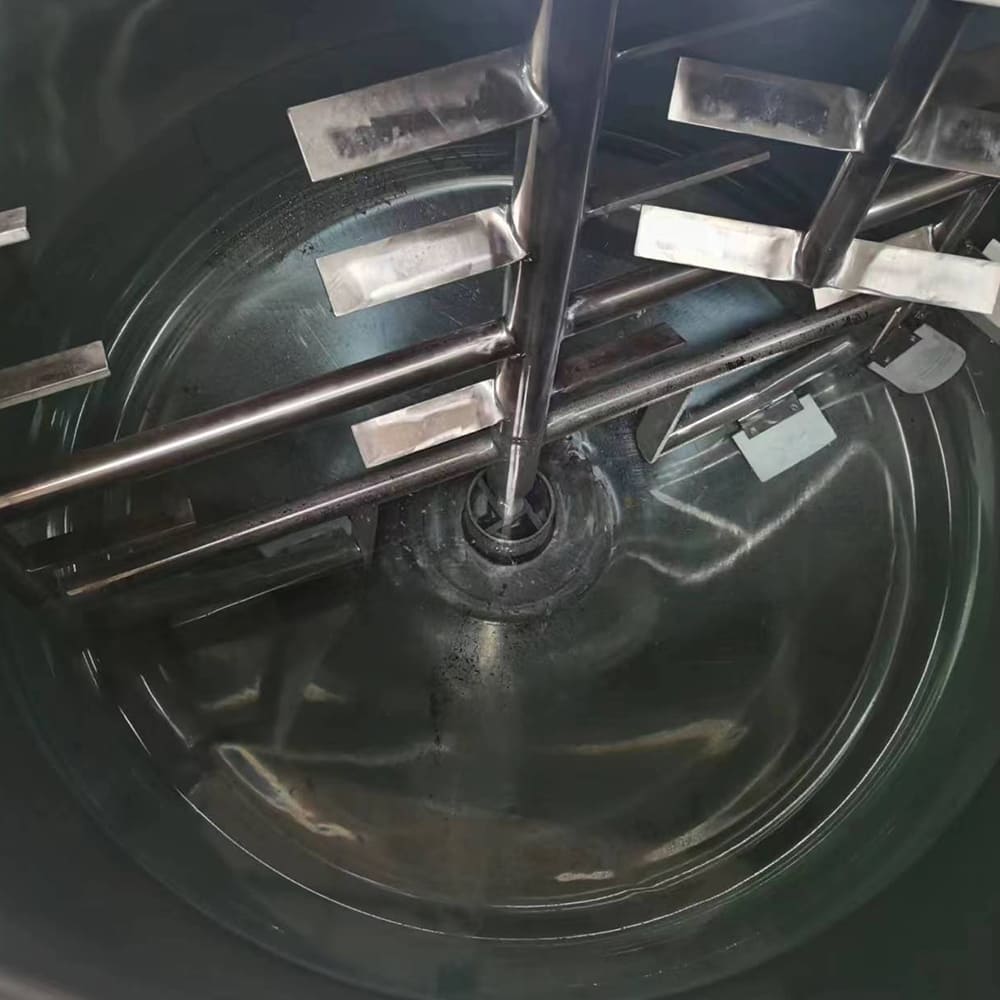

milk homogenizer Display

Can you add circulation system for the shampoo production machine?

Yes, the mixing machines can be added with a pump with circulation system. We customize upon requirements.

Is there any temperature control? Can I set a targeted temperature?

Yes,there is temperature control display and controller on the control panel. Before heating operation, just set a temperature that you want, it can keep constant temperature;

What types of containers can Yuanyang’s filling machines handle?

Our filling machines are suitable for various containers such as glass bottles, plastic bottles, bags, and boxes, automatically adjusting to different sizes and types, offering flexible production options.

How to discharge finished products?

Let the liquid products flow down naturally by valve control. Use a transfer pump to convey products to storage tanks in a short time.

Can you add load cell for material weighing for the ribbon mixer machine?

Yes, load cell is an optional choice. It is usually installed on feet. And there will be indicator on the control panel.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery