YUANYANG Continuous Band Sealing Machines: Precision Packaging for Your Industrial Mixer Products

Elevate Your Production Line with YUANYANG Continuous Band Sealing Machines

At YUANYANG, we've been at the forefront of industrial mixer and agitator manufacturing since 2008, providing comprehensive solutions that span the entire production process. While our vacuum homogenizers, high shear mixers, and emulsifying mixers are renowned for their quality, we understand that the integrity of your product extends to its final package. That's why we offer state-of-the-art continuous band sealing machines for mixers, designed to perfectly complement the products prepared by our advanced mixing equipment.

Precision Sealing for Mixer-Prepared Products

Ensuring product integrity and extending shelf life is paramount. Our continuous band sealing machines provide reliable, airtight, and tamper-evident seals for a wide range of packaging materials, including various films and pouches. Whether you're packaging creams, lotions, sauces, or other semi-liquid and viscous products processed by your YUANYANG industrial mixers, our sealing machines deliver consistent, professional results. They are engineered for efficiency and precision, crucial for maintaining product quality from the moment it leaves your mixer to the hands of your customer.

Seamless Integration with YUANYANG Production Lines

YUANYANG is more than just a mixer manufacturer; we are your partner for complete production line equipment. Our expertise allows us to provide an integrated solution that includes mixing equipment, storage tanks, filling machines, capping machines, labeling machines, and critically, sealing machines. Integrating a YUANYANG continuous band sealer into your existing or new production line, especially alongside our industrial mixers, ensures optimal workflow and compatibility. Benefit from our turnkey services, offering free technical training and one-stop installation support, simplifying your equipment setup and operation.

YUANYANG Quality & Support You Can Trust

Our commitment to excellence is unwavering. YUANYANG has obtained multiple CE certifications, underscoring our dedication to safety and health standards in all our machinery. With a vision to become the best industrial mixer and agitator manufacturer in the world, we continually strive to deliver robust, reliable equipment that meets global benchmarks. When you choose YUANYANG for your continuous band sealing machine for mixers, you're investing in proven technology, backed by unparalleled customer support and a legacy of manufacturing expertise. Partner with us for a complete, high-performance solution that propels your business forward.

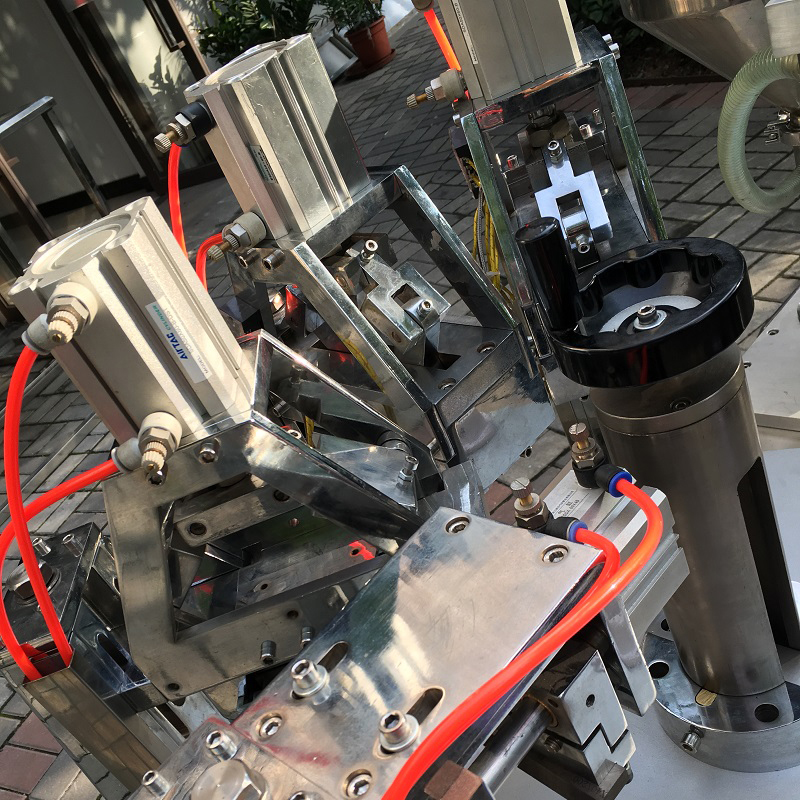

continuous band sealing machine for mixers Display

Can the capping head lift up and down?

Yes, the servo capping machines have servo motors for adjustment of capping height, can achieve lift up and down directly by touch screen control.

What capacity do you provide for vacuum emulsifying mixer machine?

We can supply from 50 Liters to 5000 Liters for mixing tanks,but we recommend maximum 1000L for vacuum emulsifier homogenizer,whose the package sizes is just ok for regular 40” HQ container.

What types of containers can Yuanyang’s filling machines handle?

Our filling machines are suitable for various containers such as glass bottles, plastic bottles, bags, and boxes, automatically adjusting to different sizes and types, offering flexible production options.

Can the screw feeding machine be customized according to my packing machine?

Yes, the screw feeder can be customized according to the packing machine, including the discharge outlet size and height.

What cutting method does the granules packaging machine have?

There are in-line cutting, pattern cutting, and in-line continuous bag cutting.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery