YUANYANG Automatic Sealing Machines: Precision, Efficiency, and Reliability for Your Production Line

YUANYANG Automatic Sealing Machines: Precision, Efficiency, and Reliability for Your Production Line

While YUANYANG is globally recognized as a leading manufacturer of industrial mixers and agitators, our expertise extends far beyond to encompass complete production line equipment. Since 2008, we have proudly offered comprehensive solutions, including critical end-of-line machinery. Among these, our advanced automatic sealing machines stand out, playing a pivotal role in ensuring product integrity, extending shelf life, and presenting your products professionally to the market.

Elevate Your Packaging with YUANYANG's Sealing Solutions

In today's competitive landscape, the final seal is as crucial as the product within. YUANYANG's automatic sealing machines are engineered to deliver consistent, high-quality seals that instill confidence. Designed for a wide range of applications, our machines help businesses achieve:

- Unmatched Efficiency: High-speed operation to significantly boost your packaging throughput and reduce labor costs.

- Superior Product Protection: Secure, tamper-evident seals that safeguard your product against contamination and leakage.

- Consistent Quality: Precision engineering ensures uniform seals, enhancing YUANYANG image and consumer trust.

Key Features and Advantages of Our Automatic Sealing Machines

Our commitment to excellence is embedded in every piece of equipment. YUANYANG's automatic sealing machine range incorporates state-of-the-art technology to provide maximum benefits:

- Versatile Compatibility: Adaptable to various container types and materials, including bottles, jars, and pouches, across diverse industries like cosmetics, food & beverage, pharmaceuticals, and chemicals.

- Robust Construction: Built with high-quality, durable materials for long-term reliability and minimal downtime in demanding industrial environments.

- User-Friendly Operation: Intuitive controls and easy maintenance procedures ensure seamless integration and operation within your production flow.

- Seamless Integration: Designed to fit perfectly within a complete YUANYANG production line, ensuring harmonious operation with our filling, capping, and labeling machines.

- CE Certified Assurance: Each machine proudly carries CE certification, signifying compliance with stringent European safety, health, and environmental protection requirements – a testament to our global standards.

YUANYANG: Your Partner for Turnkey Production Excellence

Choosing YUANYANG means choosing a partner dedicated to your success. We don't just supply machines; we provide comprehensive solutions. When you invest in a YUANYANG automatic sealing machine, you benefit from our unparalleled support, including free technical training and one-stop installation support, offering a full set of turnkey services.

As Yuanyang continues its journey to become the best industrial mixer and agitator manufacturer in the world, our expanded offerings, including high-performance automatic sealing machines, reinforce our commitment to providing complete, cutting-edge solutions for your entire production line. Trust YUANYANG to deliver the precision, efficiency, and reliability YUANYANG deserves. Visit yuanymachinery.com to explore how we can optimize your packaging processes.

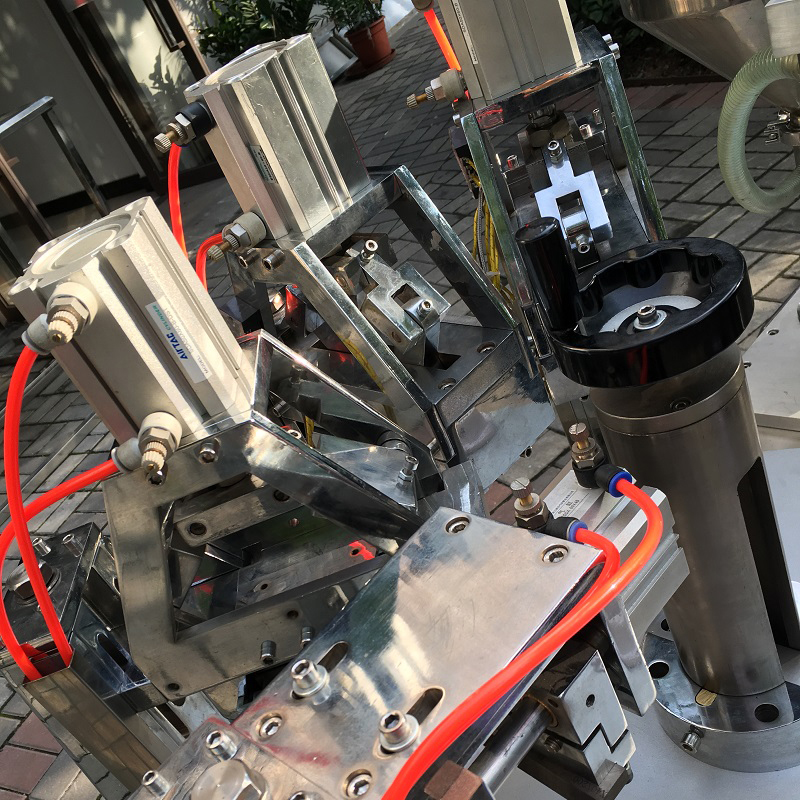

automatic sealing machine Display

What’s the production time of this semi automatic filler?

Normally it only takes 2-7 days to produce. Most often the popular 100-1000g filling range type is in stock.

Can you customized contact materials stainless steel 316L for the detergent powder making machine ?

Yes, we provide customization service upon requirements. The contact parts can be SUS304 or SUS316L. But the cost will be more.

What’s the standard discharge outlet size? Can you customize a small or bigger outlet pipe?

The standard discharge outlet is 2 inch, it can customized smaller 1.5 inch, or bigger 2.5 inch and so on.

What type of container is the induction heat sealing machine suitable for?

The bottle cap closing machine is suitable for both plastic and glass bottles, but the cap should be plastic type.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery