Automatic Filling Machine | YUANYANG

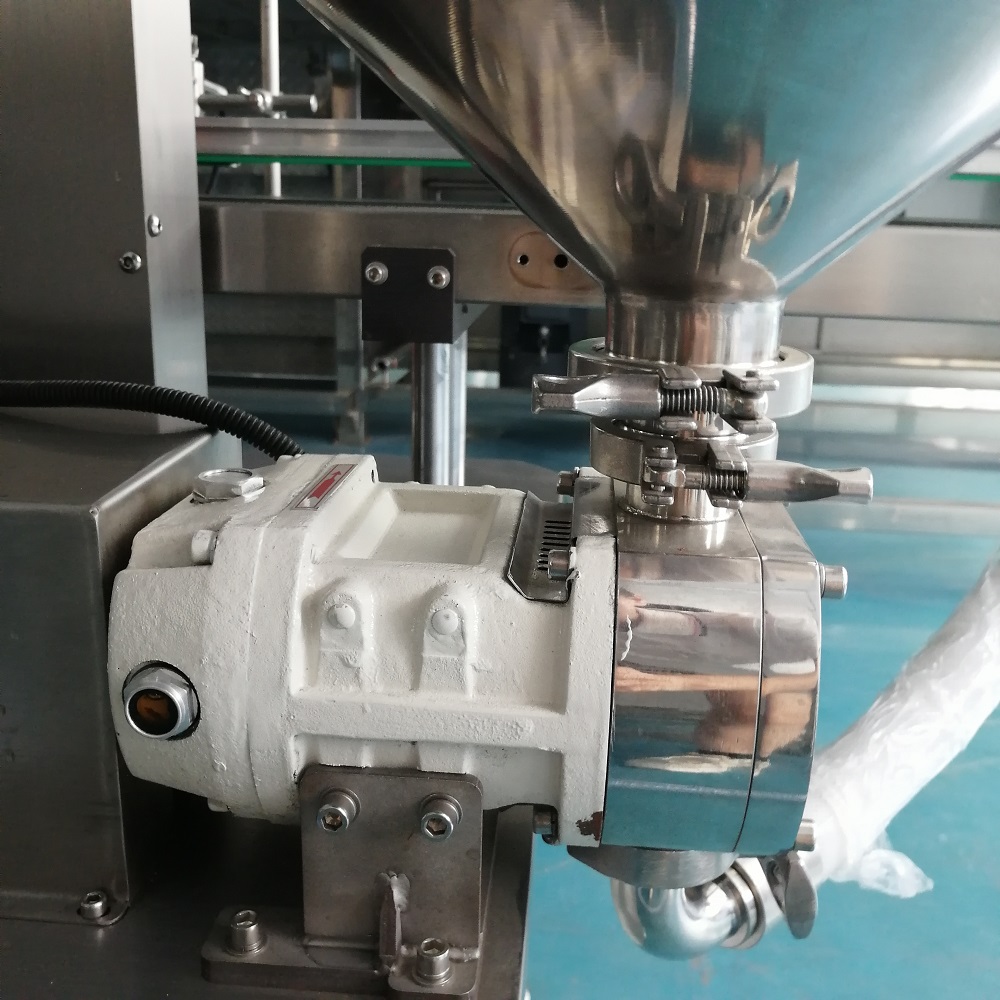

Automatic Single Head Rotor Pump Filling Machine

High-Precision Liquid Filling

YUANYANG's Automatic Single Head Rotor Pump Filling Machine provides precise and efficient filling for a wide range of liquids. This machine is ideal for various industries, including food, beverage, cosmetics, and pharmaceuticals, ensuring consistent product quality and minimizing waste. Its robust design ensures long-term reliable operation.

Integrated Liquid Feeder System

The integrated liquid feeder system seamlessly integrates with the filling mechanism, offering smooth, uninterrupted operation. This feature optimizes the filling process, reducing downtime and increasing overall productivity. The system is easily adjustable to accommodate various viscosity levels.

Easy Operation & Maintenance

Designed with user-friendliness in mind, our filling machine boasts an intuitive control panel and easy-to-access components, simplifying operation and maintenance. Minimal training is required, reducing operational costs and maximizing uptime. Regular maintenance is straightforward, prolonging the machine's lifespan.

Complete Turnkey Solutions from YUANYANG

As a leading provider of complete production line solutions, YUANYANG offers more than just the filling machine. We provide comprehensive support, including installation, technical training, and after-sales service. Our turnkey solutions streamline your production process and ensure a seamless integration of our equipment into your facility. Benefit from our expertise and years of experience.

About YUANYANG: Your Reliable Partner

YUANYANG is a trusted manufacturer of industrial mixing and blending equipment, with a proven track record since 2008. We are CE certified, demonstrating our commitment to safety and quality. We offer a wide range of machines, including mixers, blenders, and complete production lines. Contact us today for a customized solution.

Automatic Single Head Rotor Pump Filling Machine with Liquid Feeder for sale Display

What types of containers can Yuanyang’s filling machines handle?

Our filling machines are suitable for various containers such as glass bottles, plastic bottles, bags, and boxes, automatically adjusting to different sizes and types, offering flexible production options.

What’s your payment term?

Generally, we take 30% of total amount as down payment, which should be wired by T/T. The 70% balance will be paid by T/T after you inspect your machines before shipment. We also accept letter of credit although it takes more expenses. But our bank should confirm your opening bank’s credit first.

How do I choose the right machine for my production needs?

Our experts will analyze your production goals, product types, batch sizes, and packaging requirements to recommend the most suitable equipment, ensuring an efficient and cost-effective production process.

What liquid is it suitable for ?

No, this is water filling machine, only suitable for liquids like water, drinks, milk, perfume, eye drops...

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery