YUANYANG Homogenizer Product Category

YUANYANG Homogenizer Solutions

Product Range

YUANYANG offers a comprehensive Homogenizer product line including vacuum homogenizers, vacuum emulsifying mixers, high shear mixers and other vacuum mixers. Since 2008 we have specialized in complete production line equipment—mixing systems, storage tanks, filling machines, capping, labeling, sealing, inkjet printers and water treatment—to deliver reliable, scalable homogenizing solutions for manufacturers.

Key Features & Performance

Our Homogenizer systems combine high-shear rotor–stator technology with vacuum capability to produce stable emulsions, fine dispersions and consistent particle size reduction. Features include precision speed control, sanitary stainless-steel construction, efficient vacuum degassing, uniform heat control and easy-to-clean designs that meet GMP practices. Customizable options ensure performance for viscous creams, lotions, ointments, food pastes and chemical suspensions.

Turnkey Lines & After-Sales Support

YUANYANG delivers turnkey production lines and one-stop installation support. We provide free technical training, commissioning assistance and lifetime technical consultation to ensure rapid startup and sustained production efficiency. Our integrated approach minimizes supplier friction and accelerates time-to-market for products using homogenizers.

Certification & Compliance

YUANYANG has obtained multiple CE certifications to meet EU safety and health requirements. While CE denotes conformity with essential safety directives, our engineering also focuses on durability, operator safety and process reliability—especially important for regulated industries like cosmetics and pharmaceuticals.

Applications & Industries

YUANYANG Homogenizer equipment serves cosmetics, personal care, pharmaceutical, food, adhesive and specialty chemical manufacturers. Typical applications include creams, lotions, sauces, suspensions, emulsions and highly viscous formulations where consistent texture, stability and shelf life are critical.

Why Choose YUANYANG

As one of China’s leading industrial mixer and agitator manufacturers, YUANYANG combines technical expertise, CE-compliant products and end-to-end services to become your trusted homogenizing partner. Visit https://www.yuanymachinery.com/ to explore models, request specifications or arrange a consultation with our experts.

Homogenizer Display

How do you ensure the long-term stable operation of the equipment?

We provide comprehensive after-sales services, including installation, debugging, training, and regular maintenance, ensuring stable equipment operation.

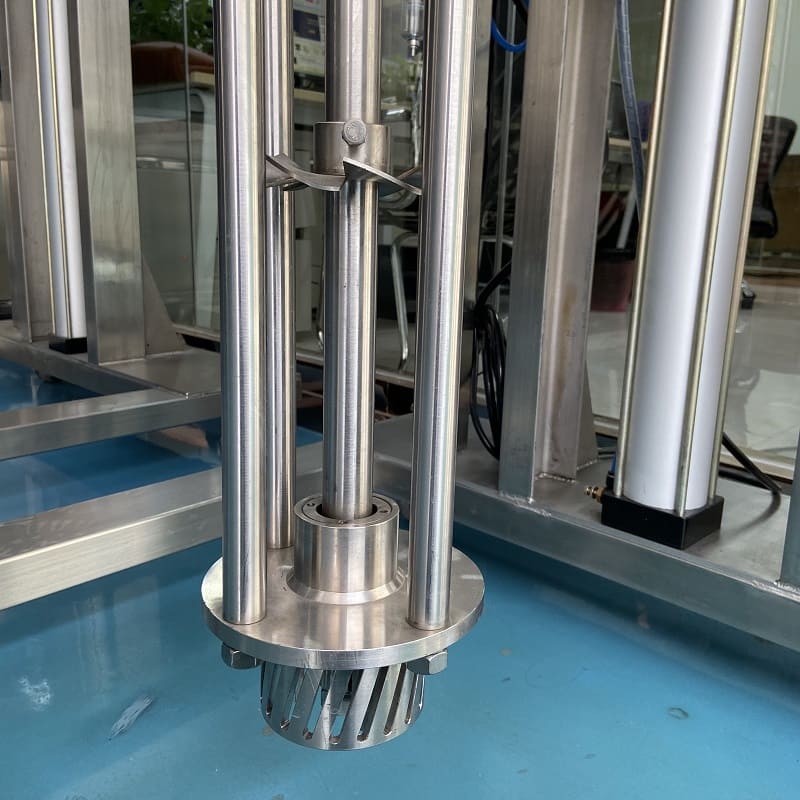

What’s the rotation speed of the bottom homogenizer head of the liquid detergent mixer?

The standard homogenizer is with high speed 3000 rpm, we can customize other bigger speed according to actual needs.

How does the rotor and stator work?

When the equipment is running, the rotor drives the blade to rotate at a high speed, generating a strong centrifugal force field, and forming a negative pressure zone in the center of the rotor, which inhales the material liquid. Under the action of centrifugal force, the material spreads from the center to the four sides, and is subjected to the stirring and shearing action of the blades during the diffusion process. The material is subjected to further shearing action in the narrow gap between the end face of the blade and the inner side of the stator tooth ring, and then enters the narrow gap between the rotating tooth and the fixed tooth of the inner ring, and is affected by mechanical force and hydrodynamics effect, resulting in shearing, friction and impact, so that dispersed phase particles or droplets are broken. As the linear speed of the tooth is gradually increased from the inner ring to the outer ring, the crushing environment of the material is continuously improved, and the purpose of homogenizing emulsification is finally achieved.

Can you add more layer to filter different sizes for the industrial shaker machine?

Yes, we can customize 1-5 layers according to needs.

How to achieve vacuum environment?

The vacuum pump is a device used to generate vacuum, which can draw out the gas in the container to form a vacuum environment. Close wall pipe valves,only open the vacuum pipe pass-by valve,also open the water inlet of vacuum pump,then operate vacuum button. After the the tank get the standard pressure such -0.05Mpa (check the pressure gauge), stop the vacuum operation,close the pass-by valve.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery