Liquid Soap Mixer Machine Price

# Liquid Soap Mixer Machine Price – High-Quality & Cost-Effective Solutions

Why Choose YUANYANG Liquid Soap Mixer Machines?

YUANYANG is a trusted China-based industrial mixer manufacturer specializing in high-performance liquid soap mixer machines. Since 2008, we’ve provided CE-certified mixing solutions with competitive liquid soap mixer machine prices, ensuring efficiency, durability, and precision for your production needs.

Key Features of Our Liquid Soap Mixers

Our vacuum emulsifying mixers and high-shear mixers ensure uniform blending, preventing separation and improving product consistency. Key benefits include:

- Stainless steel construction for hygiene & durability

- Adjustable speed & temperature control for customized mixing

- CE-certified safety compliance for EU market access

Affordable Liquid Soap Mixer Machine Price

Looking for a cost-effective liquid soap mixer machine price without compromising quality? YUANYANG offers budget-friendly options with advanced technology, ensuring high ROI for small and large-scale manufacturers.

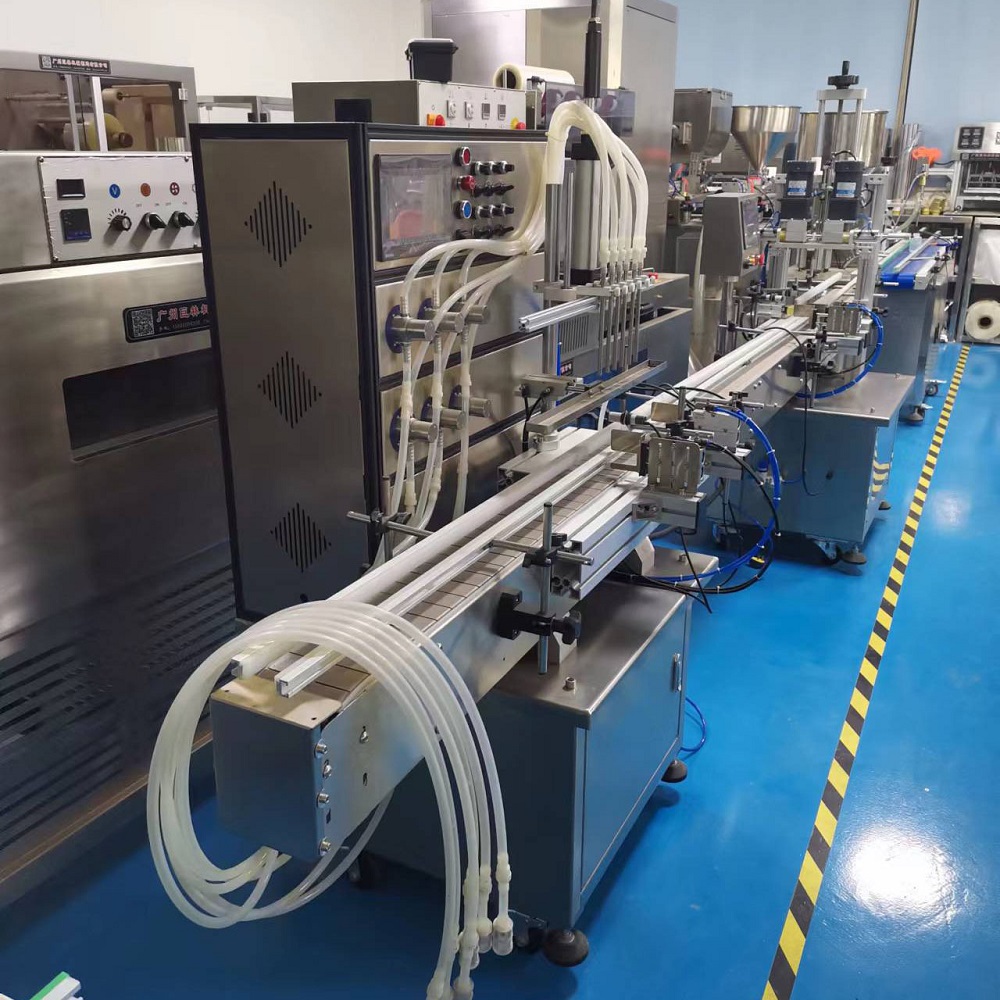

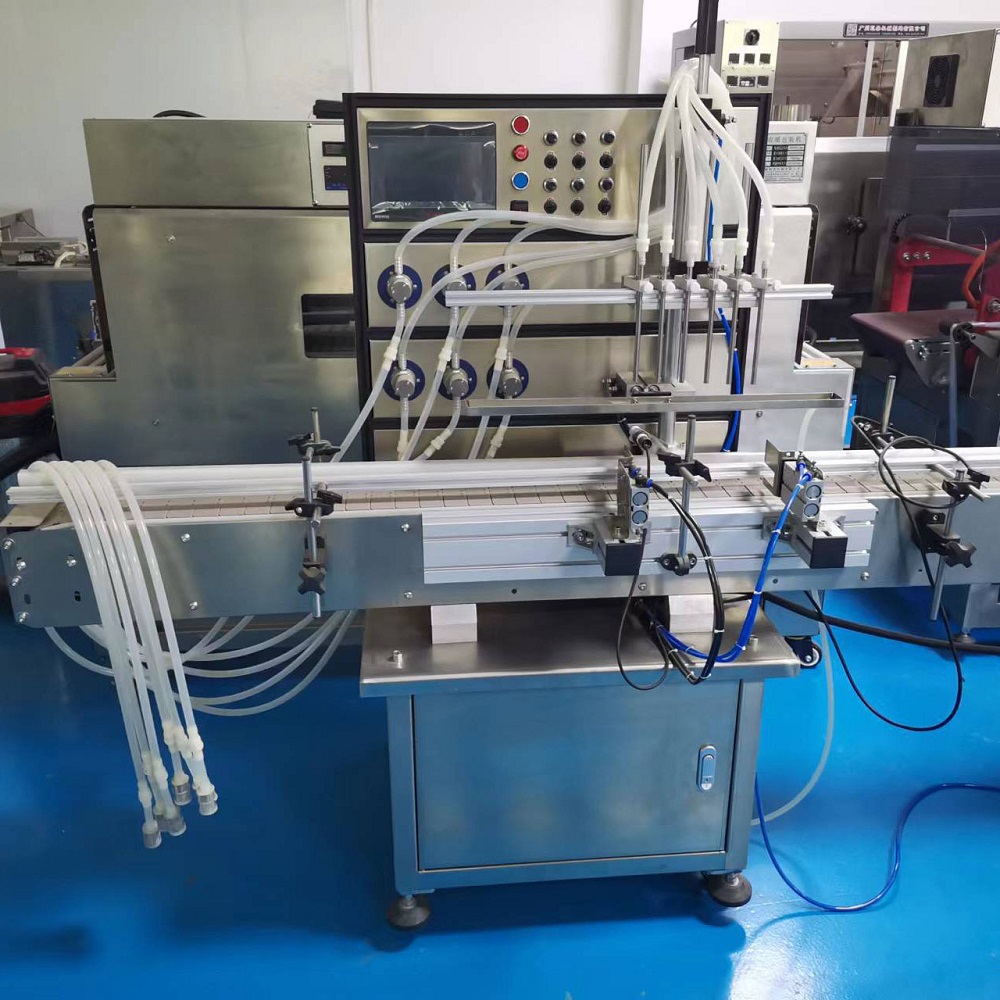

One-Stop Production Line Support

Beyond mixers, we provide complete production lines, including filling, capping, and labeling machines. Our free technical training and turnkey installation support streamline your soap manufacturing process.

Reliable CE-Certified Industrial Mixers

All YUANYANG liquid soap mixer machines meet CE standards, ensuring compliance with European safety regulations. Trust a manufacturer with over 15 years of expertise in industrial mixing solutions.

Upgrade your soap production today with YUANYANG’s High Quality liquid soap mixer machines at competitive prices!

liquid soap mixer machine price Display

What minimum and maximum caps size can the bottle capper machine be suit for?

The cap diameter of standard 4 wheels capping machine is 20-75mm, but can be slightly customized according real cases.

Do you provide installation service locally?

Yes,we can provide installation service.Generally we’ll send one or two technicians to install your machines ordered from us. You should take care of round-trip tickets, hotels, meals and other accommodations. Daily wage for each person is USD100.

But actually,most products are installed before shipment and some are packed as a complete set. When you receive them,normally you only need to install simply. No need to ask professional engineer for help.

Do you have CE certificate for the homogenizing mixer, which is a must of custom clearance for goods imported to European countries?

Yes, we have applied CE for the homogenizing mixers, all the mixers are manufactured according to the standard of CE.

How can you guarantee the bottom homogenizer will not leak liquids?

The bottom homogenizer adopts German mechanical sealing, As long as clients operate correctly, follow the instructions, this leakage is hardly to happen for over tens years or longer. But once the leakage accrues, just contact us to get a mechanical sealing to replace it.

Machine seal, as an indispensable sealing element in mechanical equipment, its core function is reflected in many aspects. First of all, it effectively prevents the leakage of liquid, gas or solid particles inside the machine through a tight sealing effect, as well as the intrusion of external impurities, so as to ensure that the internal environment of the machine is dry and clean.

This function is essential for extending the service life of machine equipment. Secondly, when the machine is sealed at high speed, it can prevent the condensation of water vapor caused by the heat generated by friction and play an anti-fog role. At the same time, it can effectively isolate the dust, particles and impurities generated during the work process to protect the equipment from damage.

In addition, the seal can also play an excellent waterproof role in wet environments, ensuring that the inside of the equipment is not affected by water erosion. In summary, the seal not only protects the normal operation of the mechanical equipment, but also provides a strong guarantee for the production and family life of all walks of life through its excellent sealing performance.

Can you add load cell system also for the liquid detergent making machine?

Yes, we add load cell upon requirements. Each mixer with 3 sets of load cell, and signal box, and display panel.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery