High-Quality Agitator Mixing Tanks

# Agitator Mixing Tanks: Efficient Industrial Blending Solutions

What Is an Agitator Mixing Tank?

An agitator mixing tank is a high-performance industrial vessel designed for blending, homogenizing, and processing liquids, semi-liquids, and viscous materials. Equipped with a motor-driven agitator, these tanks ensure uniform mixing, reducing processing time while maintaining product consistency.

Why Choose YUANYANG’s Agitator Mixing Tanks?

YUANYANG is a leading China-based manufacturer specializing in industrial mixing solutions. Our agitator mixing tanks feature:

- Robust Construction: Stainless steel or customized materials for durability.

- Precision Mixing: Adjustable speed for optimal blending.

- CE Certification: Compliant with EU safety standards.

- Turnkey Support: Free technical training and installation assistance.

Applications of Agitator Mixing Tanks

Ideal for industries like:

- Chemical Processing: Uniform dispersion of raw materials.

- Food & Beverage: Gentle yet thorough mixing for consistent texture.

- Pharmaceuticals: Hygienic blending for sensitive formulations.

- Cosmetics: Smooth emulsification for creams and lotions.

Customizable Solutions for Every Need

YUANYANG offers tailored agitator mixing tanks with:

- Variable Capacities: From small batches to large-scale production.

- Specialized Agitators: Paddle, propeller, or anchor designs.

- Integrated Systems: Compatible with storage tanks and filling machines.

Trust YUANYANG for Reliable Mixing Equipment

With over 15 years of expertise, YUANYANG delivers high-efficiency agitator mixing tanks backed by CE certification and full-service support. Contact us for a customized solution today!

By incorporating industry-focused keywords and structured subs, this content enhances readability while optimizing SEO performance for agitator mixing tank searches.

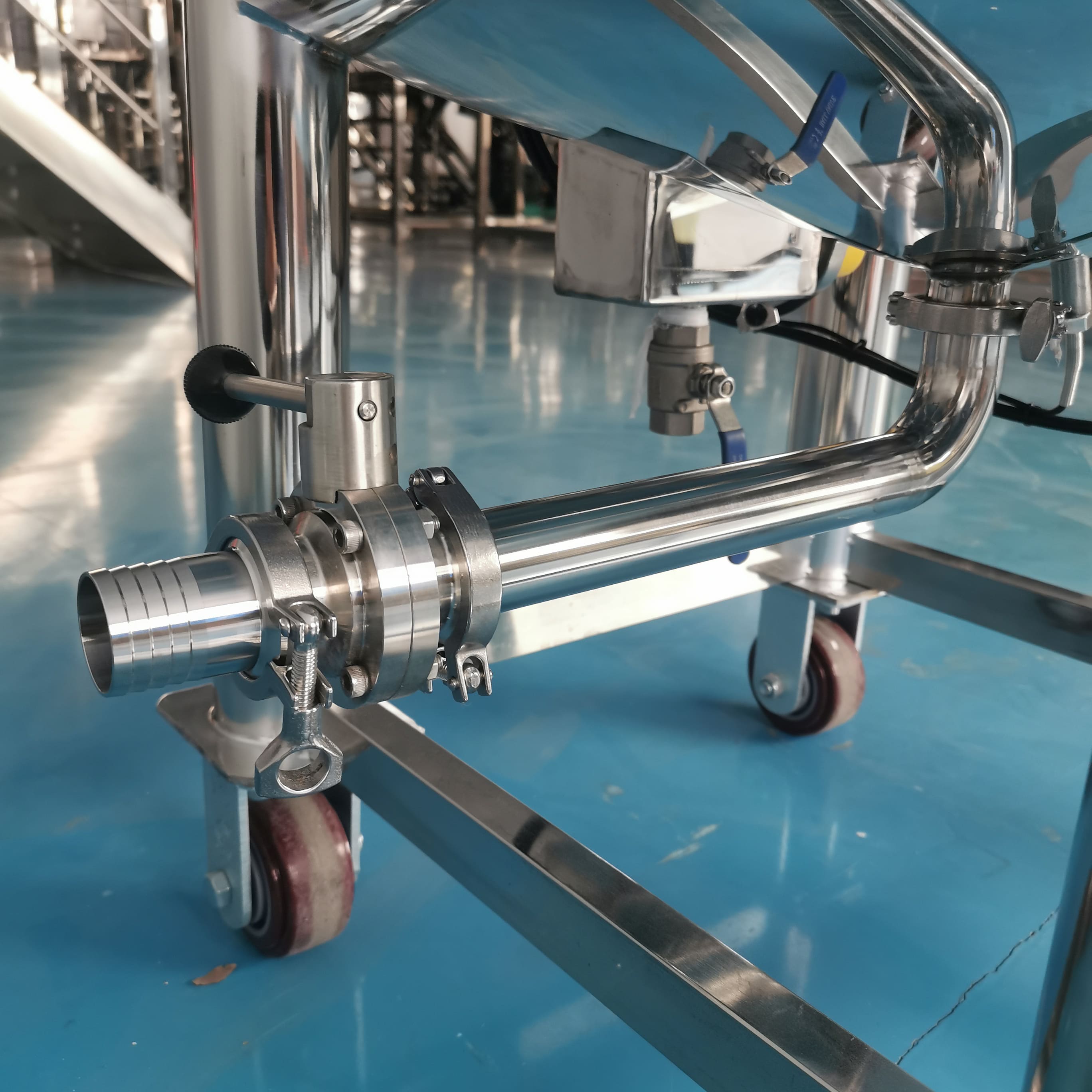

agitator mixing tank Display

How many bottles can the cream filler fill per hour?

The filling speed is affected by many factors, such as the materials thickness, viscosity, operation speed by staffs, pneumatic speed adjustment, filling volume, pressure. The filling speed varies from 500-2400 bottles per hour.

Can you make a bigger material hopper for the screw feeder machine?

Yes, the hopper capacity can be customized bigger according to needs.

Is the speed adjustable with VFD?

The chemical mixer tank is often with frequency converter. But some clients may just need a fixed speed. So we customize upon requirements.

Can you add a lid for the storage tank?

Yes, the lid can be added and customized. For example, with a central hole for overhead mixer, with a material hopper for adding powder or liquids.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery