YUANYANG Semi Automatic Perfume Filling Machines: Precision for Your Fragrances

YUANYANG: Elevating Your Fragrance Production with Semi-Automatic Perfume Filling Machines

Precision and Flexibility: Why Choose Semi-Automatic Perfume Filling?

For businesses seeking meticulous control and adaptability in their fragrance packaging, semi automatic perfume filling machines offer an unparalleled solution. Ideal for small to medium batch production, product variations, or delicate, high-value liquids, these machines provide the perfect balance between manual control and automated efficiency. They empower manufacturers to handle diverse bottle sizes and complex designs with ease, ensuring each precious drop of perfume is filled accurately and consistently, minimizing waste and maximizing product integrity. This flexibility makes them a cost-effective and versatile choice for burgeoning brands and established producers alike.

YUANYANG's Expertise in Complete Production Line Solutions

As one of the leading manufacturers of industrial mixers and agitators in China since 2008, YUANYANG brings extensive expertise to every facet of your production line. While renowned for our vacuum homogenizers, vacuum emulsifying mixers, and high shear mixers, our commitment extends to providing comprehensive, complete production line equipment. This includes state-of-the-art filling machines, capping machines, labeling machines, and more. Our semi automatic perfume filling machines are engineered with the same dedication to quality and performance that defines all YUANYANG products. We understand the nuances of liquid processing, ensuring seamless integration and optimal output for your valuable fragrances. All our relevant machines proudly carry multiple CE certifications, a testament to our adherence to stringent safety and health standards for the European market.

high quality Features for Optimal Perfume Filling

YUANYANG's semi automatic perfume filling machines are designed for performance and reliability. They feature intuitive controls, allowing for easy adjustment of filling volumes and speeds to match your specific product requirements. The precision dosing ensures minimal product giveaway, crucial for high-cost perfumes. Built with high-quality, corrosion-resistant materials, our machines maintain hygiene and prevent contamination, preserving the purity and integrity of your fragrances. Their compact design saves valuable floor space, making them a practical choice for facilities of all sizes, from artisanal workshops to larger production lines.

Your Trusted Partner for Turnkey Success

At YUANYANG, we don't just supply equipment; we offer a partnership for success. From initial consultation to post-installation support, our team provides free technical training and one-stop installation support, delivering a full set of turnkey services. Our vision is to become the best industrial mixer and agitator manufacturer in the world, and this commitment to excellence permeates our entire product range, including our advanced filling machines. Explore how YUANYANG can streamline your perfume production process and help you achieve superior results. Visit https://www.yuanymachinery.com/ for more information and to discover our complete range of solutions.

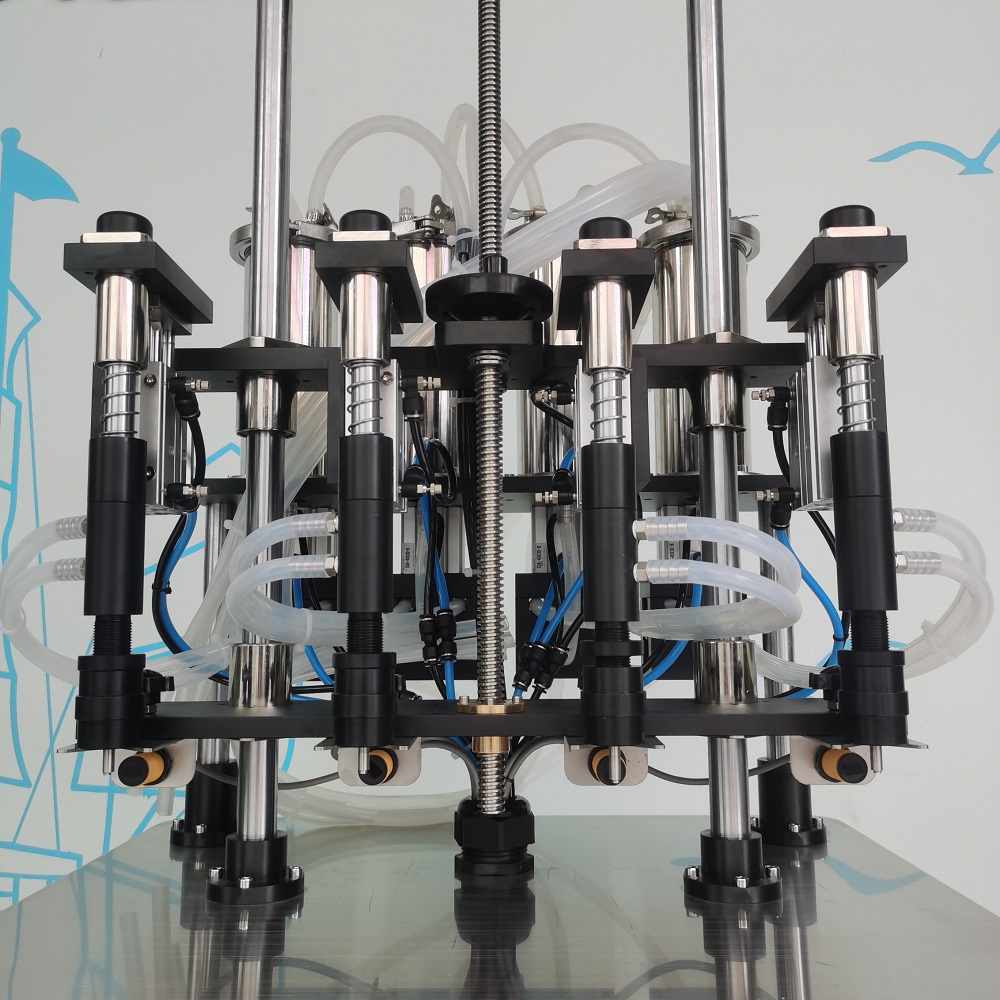

Semi automatic perfume filling machine Display

My products need specified paddle type to mixer,can you customize?

Yes,we can customized different mixing paddle type upon requirement. Just send your design to us to check.

What’s the operation process?

Operation process: put the bottle on track- > step on the foot switch - > automatically taking the bottle in - > Automatically labeling - > Automatically taking the labeled bottle out.

Can you add a date printer for the labeling machine?

Yes, a coding machine for date printing can be added with labeling machine. It can print date on labels with ink. But for more functions,such print code, pictures, bar code, it is suggested to buy a separated ink jet printer.

What’s the production time of this semi automatic filler?

Normally it only takes 2-7 days to produce. Most often the popular 100-1000g filling range type is in stock.

What are the core values of your company?

We holding the principle of surviving by quality and developing by reputation,providing solution-oriented service.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery