1000 Gallon Stainless Steel Mixing Tank | Premium Quality by YUANYANG

1000 Gallon Stainless Steel Mixing Tank

High Quality Industrial Mixing Solution

YUANYANG’s 1000-gallon stainless steel mixing tank is designed for high-capacity industrial applications. Crafted from food-grade 304/316 stainless steel, it ensures corrosion resistance, durability, and compliance with strict hygiene standards. Ideal for pharmaceuticals, cosmetics, and food processing.

Robust Construction & Durability

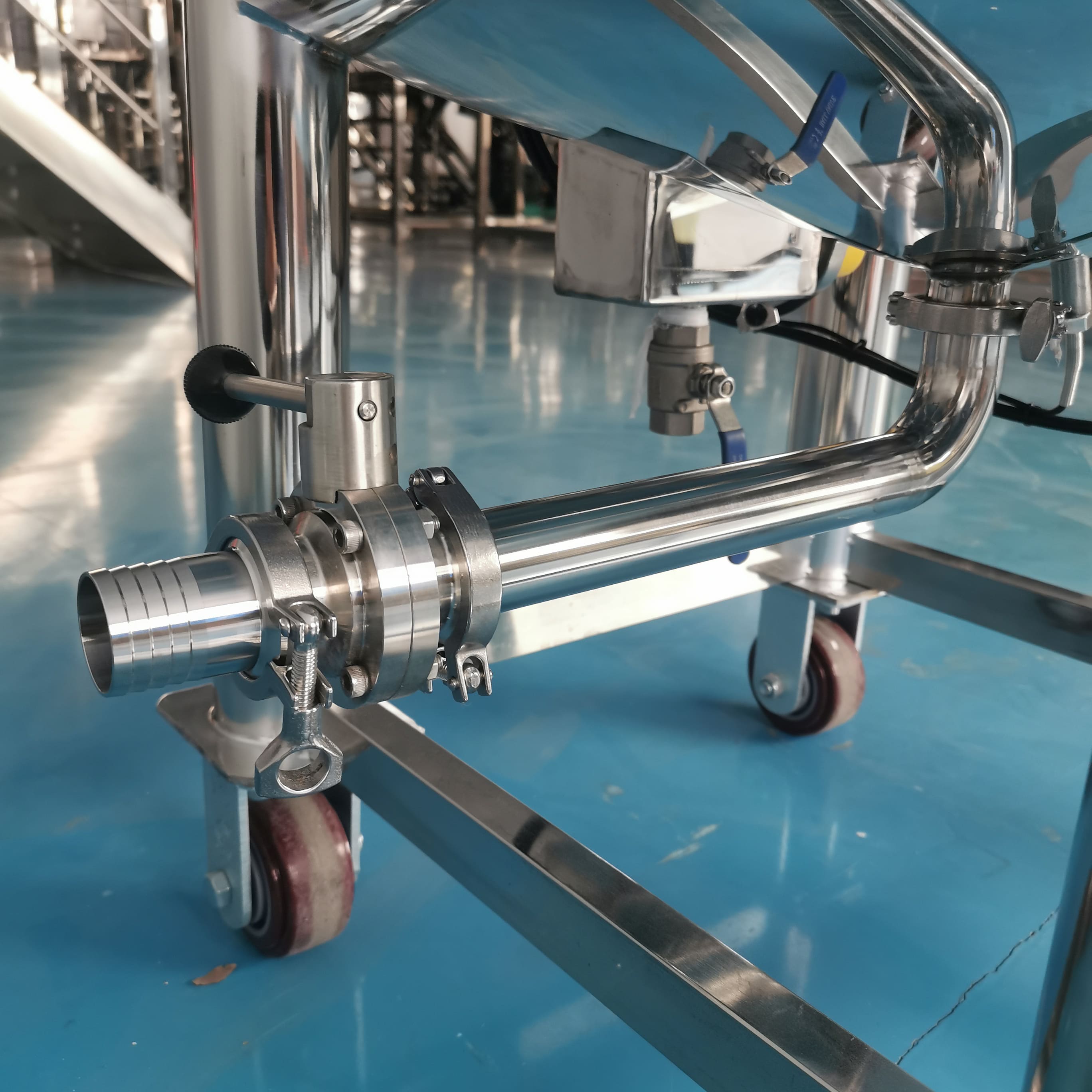

Built to withstand heavy-duty use, our mixing tanks feature reinforced welds, polished surfaces, and seamless interiors. The stainless steel structure resists rust, chemicals, and extreme temperatures, ensuring long-term reliability.

Efficient Mixing Performance

Equipped with advanced agitators and customizable mixing options, YUANYANG’s tanks deliver uniform blending for viscous or liquid products. Optional heating/cooling jackets enhance process flexibility.

CE-Certified & Safety Compliant

Our 1000-gallon tanks meet CE standards, guaranteeing safety and compliance for EU markets. YUANYANG provides full technical support and installation services for seamless integration.

Customizable & Scalable

Tailor your tank with accessories like sight glasses, CIP systems, or variable-speed agitators. YUANYANG offers turnkey solutions, including auxiliary equipment for complete production lines.

1000 gallon stainless steel mixing tank Display

Can I replace the screws of the powder bottle filling machine to pack different weight in one machine?

Yes, we can customize different screw models for the semi automatic powder packing machine, and the screw models are replaceable.

Are the equipment compliant with industry regulations?

Yes, Yuanyang’s equipment meets GMP, FDA, and other relevant industry regulations, ensuring high-quality and safety standards.

Can I add two layers of plate for the dispersion machine?

Yes, we can two or more layers of plates or blades.

Can you tell me the filling range of each specific screw model for this powder bottle filling machine?

Model 25mm can fill 5-50g; model 38mm can fill 50-500g; model 75mm can fill 500-1000g.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery