Anti-corrosion Filling Machines: Precision & Durability from YUANYANG

Anti-corrosion Filling Machines: Precision & Durability from YUANYANG

In industries dealing with harsh, corrosive liquids, reliable and safe filling is paramount. An ordinary filling machine simply won't suffice, as caustic substances can quickly degrade components, lead to costly downtime, and pose significant safety risks. At YUANYANG, a leading manufacturer of industrial mixers and complete production line equipment since 2008, we understand these critical challenges. Our state-of-the-art Anti-corrosion Filling Machines are specifically engineered to provide unparalleled precision, durability, and safety when handling even the most aggressive chemicals, acids, and other corrosive materials.

Why Anti-corrosion Filling is Critical for Your Operations

Corrosive liquids are a common reality in sectors like chemical processing, pharmaceuticals, food & beverage (for acidic products), and specialty manufacturing. Without purpose-built anti-corrosion filling solutions, businesses face numerous hazards: equipment erosion, leakage, product contamination, worker exposure, and compliance failures. Our machines are designed to mitigate these risks, protecting your investment, ensuring product integrity, and maintaining a safe operational environment. We focus on long-term performance, reducing maintenance needs and improving overall efficiency for your production line.

YUANYANG's Advanced Anti-corrosion Filling Technology

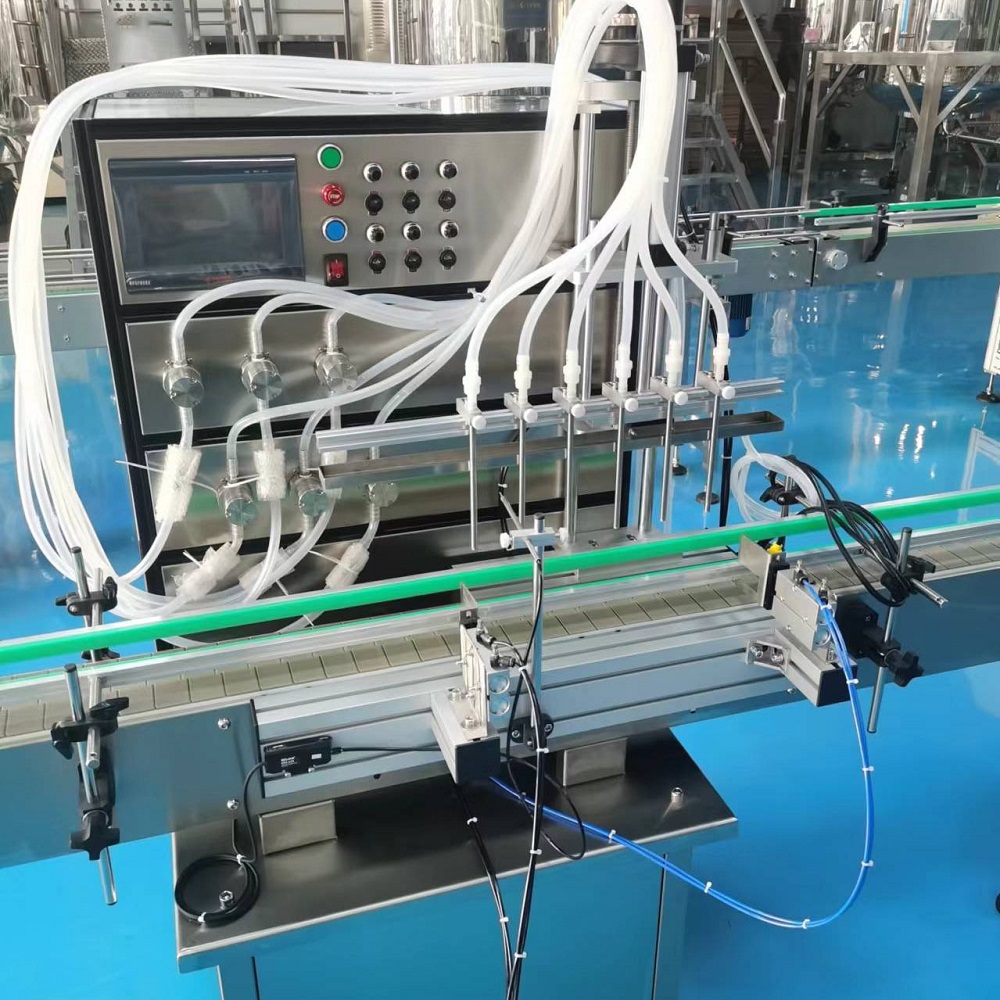

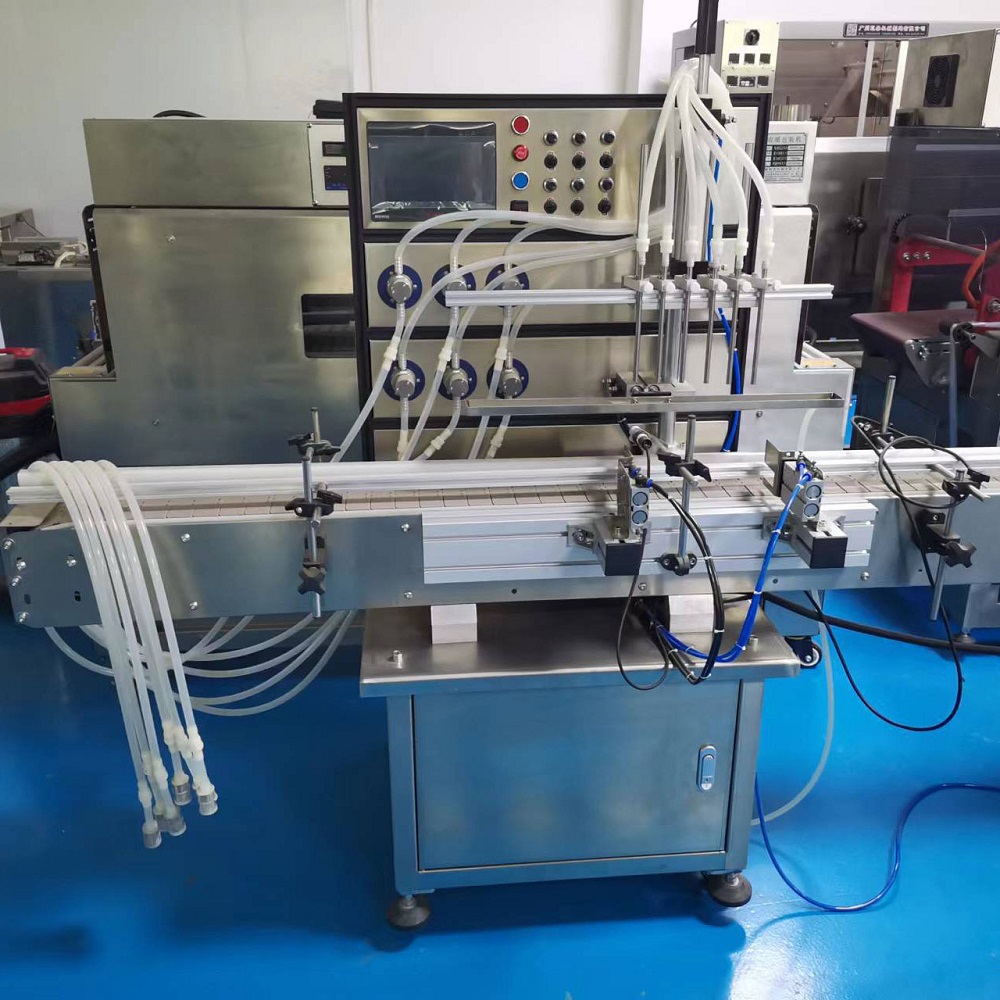

YUANYANG's Anti-corrosion Filling Machines are constructed from highly resistant materials such as high-grade PVC, PTFE, PP, ceramic components, and specialized alloys that withstand aggressive chemical attack. Each machine features a robust design, precision dosing systems, and hermetic seals to prevent leaks and spills. Whether you need to fill strong acids, alkalis, or other corrosive compounds, our technology ensures accurate, repeatable, and safe filling. As experts in industrial mixing, our deep understanding of material science extends to every piece of equipment we produce, guaranteeing the highest standards of reliability and performance.

Integrated Solutions for Your Production Line

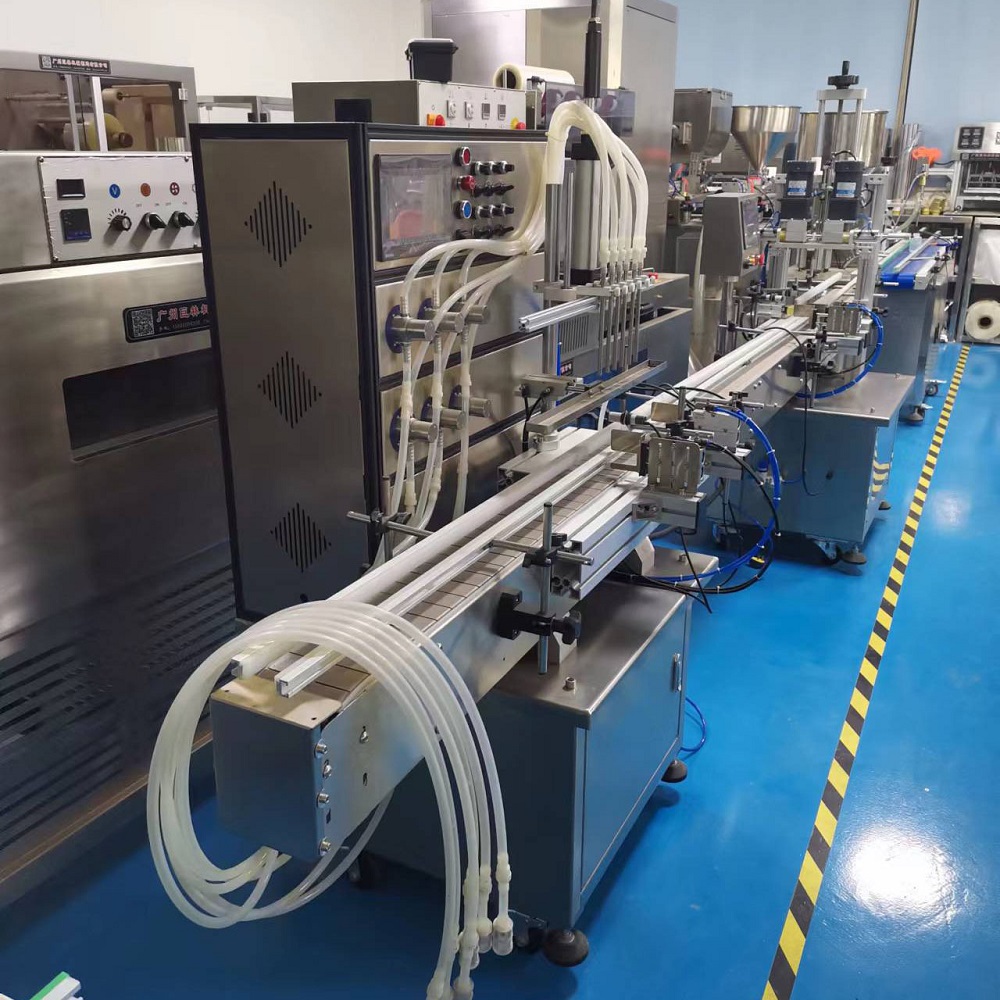

Beyond standalone excellence, YUANYANG specializes in delivering complete production line solutions. Our Anti-corrosion Filling Machines seamlessly integrate with our extensive range of equipment, including vacuum homogenizers, storage tanks, capping machines, labeling machines, and sealing machines. This comprehensive approach ensures a smooth, efficient workflow from mixing to packaging. We offer free technical training and one-stop installation support, providing a full set of turnkey services that streamline your setup and maximize your operational output.

The YUANYANG Advantage: Reliability & Global Standards

Choosing YUANYANG means partnering with a company committed to global excellence. With multiple CE certifications, our equipment adheres to stringent European safety and health standards, reflecting our dedication to quality and reliability. Our vision is to become the best industrial mixer and agitator manufacturer in the world, and this commitment extends to every component of our product range, including our specialized Anti-corrosion Filling Machines. Experience the YUANYANG difference – where innovation meets unwavering performance.

Anti-corrosion Filling Machine Display

Can the control panel be customized to be hung on the wall?

Yes, we customize a separated control panel which can be moved and installed on the wall or other places.

Is the height of the bottle cap sealing machine adjustable?

Yes, there is a handle wheel to adjust the height of sealing head according to different bottle height.

How does the automatic bottle sealing machine work?

Electromagnetic induction sealing machine uses high-frequency electromagnetic field to act on the packaging film, resulting in an induced current inside, which will generate heat, melt the packaging film, and then form a sealing after cooling.

Is there any handle for easy movement?

Yes, there is handle for each steel tank.

Is the powder screening machine used for detergent powder?

Yes, this can be used for detergent powder. It is a detergent powder screening machine.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery